- Language:

English ▼

English ▼

English ▼

English ▼ItemNo :

Lith-PD-JS03MOQ :

1Compliance:

CE CertifiedWarranty:

1 yearDelivery Time:

5 days

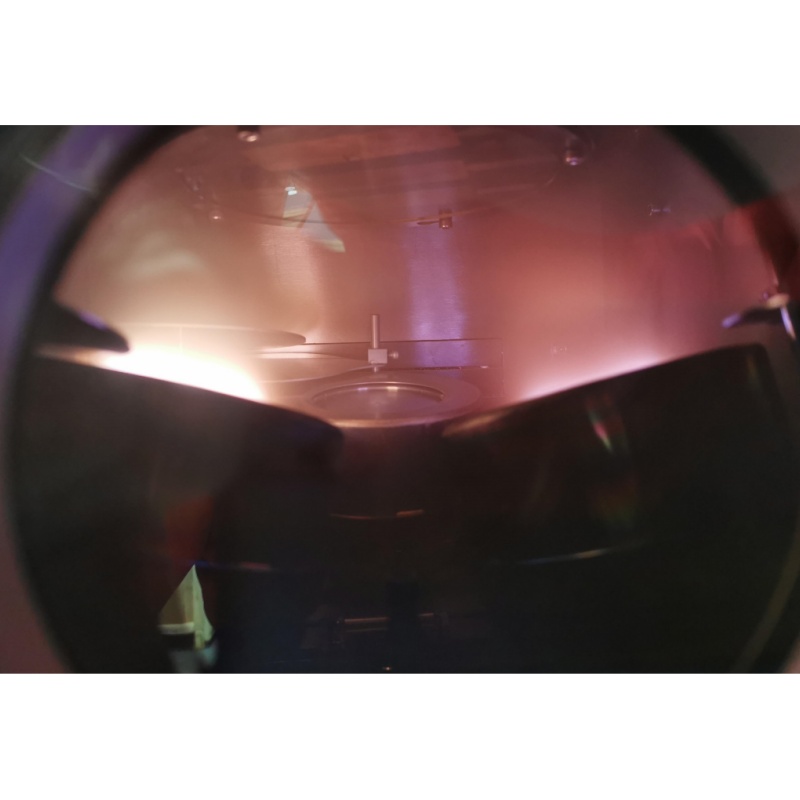

Model: Lith-PD-JS03-Multi-target For Multilayer Films Deposition

Product Overview

The Lith-PD-JS03 magnetron sputtering system is designed for scientific research institutions and university laboratories. Featuring core components system offers stable performance, high automation, and serves as a competitive alternative to imported equipment.

1. Versatile Sputtering Modes

·Compatible with both DC and RF sputtering sources, enabling deposition of metallic, non-metallic, and compound thin films.

·Supports multi-layer and composite film deposition for advanced material research.

2. Superior Film Quality

·Delivers excellent uniformity (±3%~5%) and repeatability for metals, semiconductors, and insulating materials.

3. Optimized Configuration

·Equipped with three 3-inch circular target guns, mounted in a co-focal upward sputtering arrangement.

·Adjustable sputtering area: 2–4 inches (compatible with 2–3 inch targets).

|

Parameter |

Value / Description |

|

System Dimensions (L×W×H) |

850 × 1100 × 1900 mm |

|

Chamber Dimensions (L×W×H) |

400 × 400 × 380 mm |

|

Substrate Stage |

Max temperature: 600°C (±5°C accuracy) |

|

Ultimate Vacuum |

≤ 5 × 10−5 Pa |

|

Pump-down & Holding |

≤ 8 × 10−4 Pa in 30 min; ≤ 8 Pa over 12 hours |

|

Uniformity |

Better than ±3%–5% |

|

Target Configuration |

3 guns (2–3 inch), 2–4 inch deposition area |

The Lith-PD-JS03 is ideal for depositing nitrides, oxides, and other functional films, catering to:

· Semiconductor research (e.g., conductive/dielectric layers).

· Optical coatings (anti-reflective, protective films).

· Advanced materials (multilayer structures, composite films).

1. Leveling: Ensure absolute horizontal alignment using a spirit level to guarantee film uniformity.

2. Connections: Securely attach power, cooling water, and vacuum pipelines, checking all seals for leaks.

3. Inspection: Verify no physical damage occurred during transit.

The system utilizes glow discharge of inert gases to generate ionized particles. These particles bombard the target surface, ejecting atoms/molecules that condense on the substrate to form thin films. Secondary electrons sustain plasma, enhancing deposition efficiency.

Why Choose?

· Reliability: Premium components ensure long-term stability.

· Flexibility: Dual-mode sputtering for diverse materials.

· Precision: Tight temperature/vacuum control for reproducible results.

![]()

![]()

![]()

PACKAGE:

1 Standard exported package: Internal anticollision protection, external export wooden box packaging.

2 Shipping by express, by air, by sea according to customers' requirements to find the most suitable way.

3 Responsible for the damage during the shipping process, will change the damage part for you for free.

DELIVERY TIME: 15-20 days after confirming order,detail delivery date should be decided according to production season and order quantity

ONLINE

ONLINE +86 13174506016

+86 13174506016 Louis@lithmachine.com

Louis@lithmachine.com +86 18559646958

+86 18559646958

18659217588

18659217588