- Language:

English ▼

English ▼

English ▼

English ▼

AXBattery Equipment Debuts at , Indian Agent Helps Expand Wide Market : -13 Indian Institute of Science Bengaluru India 11th- 14th January, 2026 Indian agent company:Adilab technologies pvt Ltd Recently, “”At the ,equipment attracted high attention from attendees. In order to better expand the market, TMAX's Indian agent actively communicated with industry partners at this conference and actively explored broader markets. They stated that they will utilize their own experience and resources to promote the sales and application of TMax

Read More

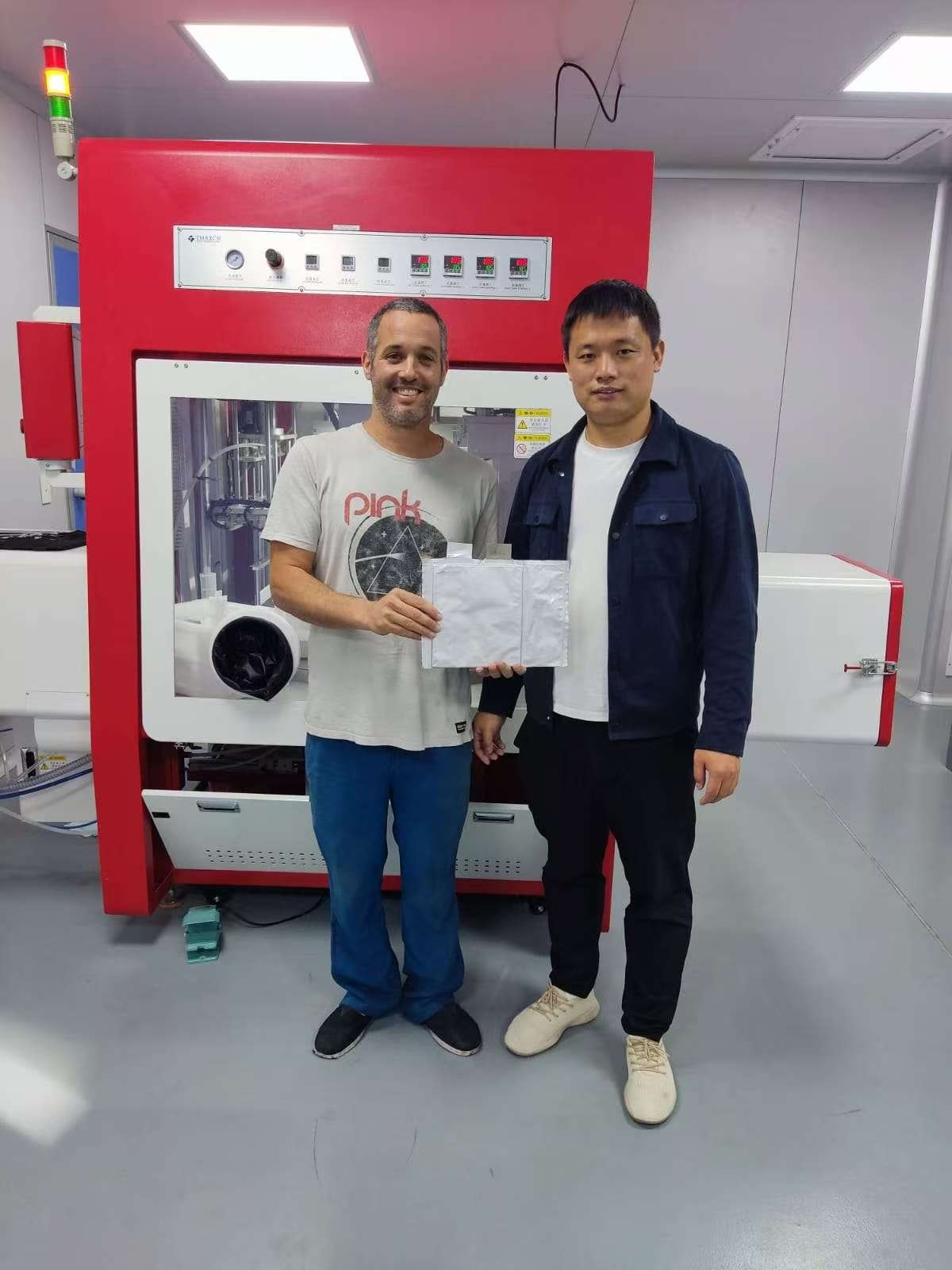

Pouch Cell Pilot Line Project-Installation&Debugging Successful Date:2026.1.19 In December 2025, TMAX successfully completed a one-month on-site commissioning and optimization of Argentina pouch cell production line project. Tmax’s engineering team conducted thorough system debugging,equipment performance to ensure maximum stability, consistency, and output efficiency. The outcome was exceptional: the facility has now commenced production of fully compliant pouch battery cell—meeting all agreed capacity, safety, and performance specifications. This milestone significantly strengthens Argentina’s battery manufacturing capability and elevates product quality standards across the value chain. Industry observers highlight this achievement as a catalyst for broader sectoral advancement—offering valuable benchmarks for academic research, industrial replication, and cross-border technology exchange. It also reinforces Argentina’s growing role in the global lithium-ion ecosystem. TMAX remains committed to long-term partnership. We welcome opportunities to support further upgrades—such as automation enhancements, capacity expansion, or next-generation cell integration—to help customer scale competitively in both regional and international markets.

Read More

430L Automatic Vacuum Ovens Delivered to Russia In December 2025, we successfully completed the shipment and delivery of 14 sets of 430L automatic vacuum ovens with three-layer independent heating to a customer in Russia, representing another milestone in our global project portfolio. Engineered for lithium-ion battery production, this vacuum oven is widely applied in the drying and baking of electrode sheets, battery cells, and cells before electrolyte injection. With precise temperature control, stable vacuum performance, and consistent operational reliability, it delivers excellent drying uniformity and process efficiency. Thanks to its strong performance and versatility in battery manufacturing applications, this vacuum oven has gained wide market acceptance and continues to be one of our most in-demand products worldwide.

Read More

LITH Delivers 21 Sets of 21700 Cylindrical Battery Pack Assembly Equipment to a Key Ukrainian Customer In December 2025, one of our key customers in Ukraine placed orders for three batches of 21700 cylindrical battery pack assembly equipment, totaling 21 units, which have now been successfully delivered. The supplied equipment includes positive electrode insulation sticker machines, double-sided spot welding machines, cutting machines, aging cabinets, and heat shrink machines, providing a comprehensive solution for cylindrical battery pack assembly. This milestone achievement highlights our extensive experience and outstanding product quality, further strengthening the trust and recognition we have earned from customers around the world. Cylindrical battery packs, such as the 21700 series, are widely used in electric vehicles, energy storage systems, and portable electronic devices, demonstrating their versatility and strong market demand. If you are looking for reliable battery pack assembly solutions, feel free to contact us—we would be happy to discuss customized solutions tailored to your needs. Contact: louis@lithmachine.com WhatsApp: +86 18659217588 Wechat: 18659217588

Read More

In October 2025, LITH delivered a container battery pack assembly line machines to Thailand, which is the first batch of the project. It mainly includes: 5V 6A 512 Channel Grading Machine; Automatic Spot Welding Machine; 11 Channel Cell Sorter; Paper Sticking Machine; PVC Heat Shrinking Machine; Aging machine; BMS Tester, Comprehensive Tester, etc. https://www.lithmachine.com/cylindrical-battery-pack-assembly-line_c111 Cell Specification: 32700 model lithium iron phosphate (LiFePO4) cells are adopted.Maximum Cell Parameters: The rated voltage is 3.2V, the maximum voltage is 3.6V, the maximum capacity is 6500mAh, and the energy density is ≥150Wh/kg, which can meet the and power supply requirements in high-capacity demand scenarios. The 4-series design enables the battery pack to have a rated voltage of 12.8V (3.2V×4), and the 7-parallel design enables the battery pack to have a capacity of 45.5Ah (6500mAh×7). The series-parallel structure can be adjusted according to customer needs to adapt to different voltage and capacity requirements. Daily Production Capacity: The assembly line is designed to have a daily production capacity of 70-75 battery packs. At the same time, the equipment supports modular expansion.Quality Control: A "three-level quality inspection system" is established, covering incoming inspection of raw materials (cells), online inspection of each process in production, and aging testing and comprehensive testing of finished products. In addition, we provide equipment operation training, regular maintenance and other services to help customers stabilize the production process and continuously ensure product quality. If you need to further understand the following information or have other needs, please feel free to contact us: Detailed technical parameter manuals, operation instructions and maintenance plans for the equipment; Expansion solutions for battery pack application scenarios (such as energy storage system integration, power tool matching, etc.).

Read More ONLINE

ONLINE +86 13174506016

+86 13174506016 Louis@lithmachine.com

Louis@lithmachine.com +86 18559646958

+86 18559646958

18659217588

18659217588