- Language:

English ▼

English ▼

English ▼

English ▼ItemNo :

LITH-PCPLMOQ :

1Place of Origin:

ChinaWarranty:

2 yearsDelivery Time:

5 days

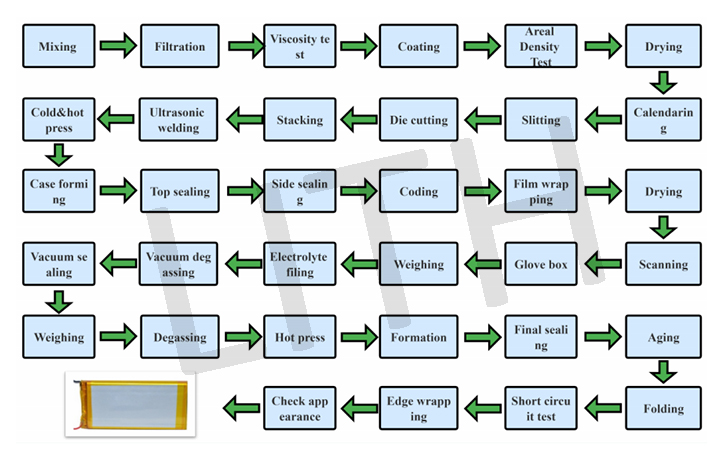

I. introduction

Pouch cell is a flexible and lightweight rechargeable battery. It features a flat, pouch-like package that holds the battery's active components. Pouch cells offer advantages such as high energy density, flexible form factor, excellent power delivery, lightweight design, improved thermal characteristics, and longer cycle life. These qualities make pouch cells a preferred choice for applications in portable electronics, electric vehicles, and renewable energy systems.

II. Machine list

|

NO. |

Process |

Item name |

|

1 |

Cathode mixing |

Electrode mixer |

|

2 |

Anode mixing |

Electrode mixer |

|

3 |

Slurry feeding |

Slurry feeding system |

|

4 |

Cathode coating |

Slot die coater |

|

5 |

Anode coating |

Slot die coater |

|

6 |

NMP recycling |

NMP recycling system |

|

7 |

Cathode electrode rolling press |

Electrode Roller Press |

|

8 |

Anode electrode rolling press |

Electrode Roller Press |

|

9 |

Cathode slitting |

Electrode slitting machine |

|

10 |

Anode slitting |

Electrode slitting machine |

|

11 |

Cathode die cutting |

Electrode die cutter |

|

12 |

Anode die cutting |

Electrode die cutter |

|

13 |

Stacking |

Automatic stacking machine |

|

14 |

Hot press test |

Hot press testing machine |

|

15 |

Case forming |

Case forming machine |

|

16 |

Sealing |

Top and side sealing machine |

|

17 |

Drying |

Vacuum oven |

|

18 |

Filling |

Automatic electrolyte filling machine |

|

19 |

Formation |

Hot press formation machine |

|

20 |

final sealing |

Final sealing machine |

|

21 |

Grading |

Grading cabinet |

|

22 |

Power auxiliary |

Dehumidification system |

|

23 |

Vacuum pump |

|

|

24 |

Air compressor |

|

|

25 |

Deionized water machine |

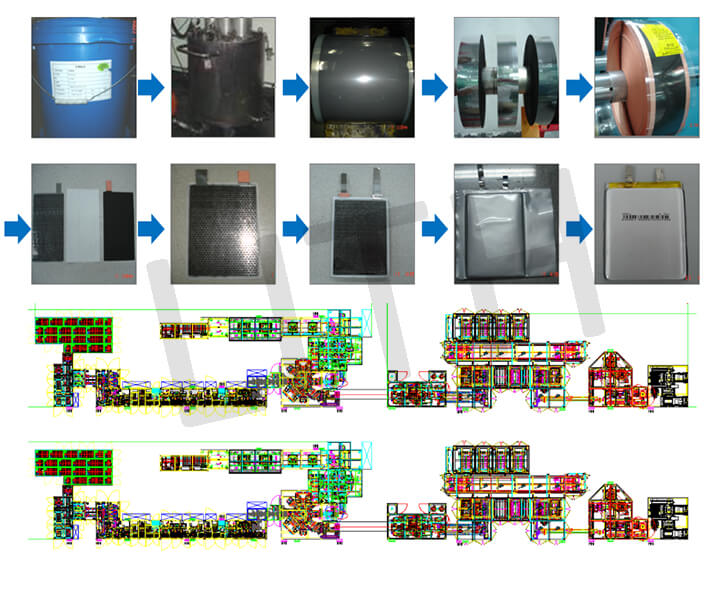

III. Plant display

V. Procurement process

Lith group follows a comprehensive procurement process to ensure a seamless experience for our customers.

Initial Consultation: We have an in-depth discussion with the customer to understand their battery production requirements, machine specifications, and budget constraints.

Proposal Preparation: Based on the consultation, we create a detailed proposal that outlines our recommended battery-making machines, pricing, delivery timelines, and additional services or support.

Proposal Presentation: We present the proposal, highlighting the features and benefits of our machines, addressing customer questions, and explaining how our solution meets their needs.

Negotiation and Agreement: We engage in negotiations to address concerns and modify the proposal if needed, aiming to reach a mutual agreement on pricing, terms, and conditions.

Purchase Order: The customer issues a purchase order (PO) that formalizes the agreement, specifying quantities, prices, delivery dates, and contractual obligations.

Order Fulfillment: We manufacture or source the battery-making machines according to agreed specifications, conducting quality control checks to ensure high performance and reliability.

Shipment and Delivery: We handle packaging, transportation, and customs clearance, providing tracking information and updates on the shipment's status.

Installation and Training: Our technicians offer installation services and comprehensive training on machine operation, maintenance, and troubleshooting.

Post-Sales Support: We provide ongoing customer support, including assistance with spare parts, maintenance, upgrades, and expansions, to ensure customer satisfaction.

By following this streamlined procurement process, we deliver high-quality battery-making machines tailored to our customers' requirements while providing excellent support throughout their lifecycle.

VI. Manufacturing Cycle and Planning

|

No. |

Project |

1st month |

2nd month |

3rd month |

4th month |

5th month |

6th month |

||||||

|

1 |

◎ Confirmation of idea/plan/specification |

|

|

|

|

|

|

|

|

|

|

|

|

|

2 |

◎ Customized design for key parts |

|

|

|

|

|

|

|

|

|

|

|

|

|

3 |

◎ Mechanical part design |

|

|

|

|

|

|

|

|

|

|

|

|

|

4 |

◎ Control part design |

|

|

|

|

|

|

|

|

|

|

|

|

|

5 |

◎ Procurement of processed parts/outsourced parts |

|

|

|

|

|

|

|

|

|

|

|

|

|

6 |

◎ Mechanical assembly |

|

|

|

|

|

|

|

|

|

|

|

|

|

7 |

◎ Electrical debugging |

|

|

|

|

|

|

|

|

|

|

|

|

|

8 |

◎ Single test |

|

|

|

|

|

|

|

|

|

|

|

|

|

9 |

◎ Linkage trial operation and on-site customer placement |

|

|

|

|

|

|

|

|

|

|

|

|

|

10 |

◎ Trial run/final acceptance |

|

|

|

|

|

|

|

|

|

|

|

|

![]()

![]()

![]()

PACKAGE:

1 Standard exported package: Internal anticollision protection, external export wooden box packaging.

2 Shipping by express, by air, by sea according to customers' requirements to find the most suitable way.

3 Responsible for the damage during the shipping process, will change the damaged part for you for free.

DELIVERY TIME:15-20 days after confirming the order, detail delivery date should be decided according to

production season and order quantity.

ONLINE

ONLINE +86 13174506016

+86 13174506016 Louis@lithmachine.com

Louis@lithmachine.com +86 18559646958

+86 18559646958

18659217588

18659217588