- Language:

English ▼

English ▼

English ▼

English ▼ItemNo :

Lith-TK-JS02MOQ :

1Compliance:

CE CertifiedWarranty:

1 yearDelivery Time:

5 days

Model: Lith-TK-JS02-Precision Thin Film Deposition for Nanotechnology

I. System Overview

Features & Applications

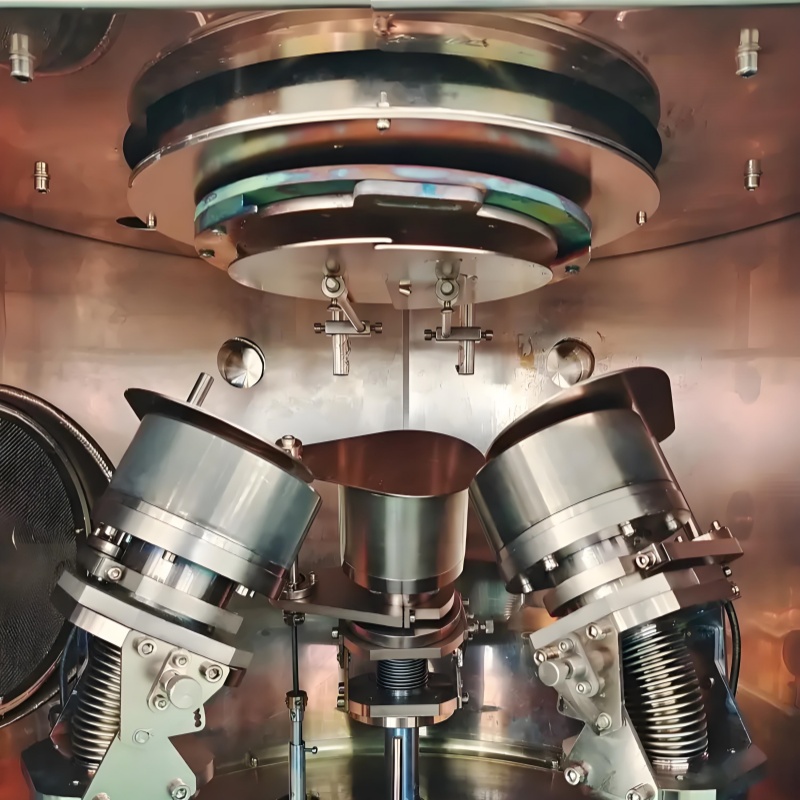

The Lith-TK-JS02 is a high-vacuum multi-target magnetron sputtering coating system, integrating advanced components such as:

· Sputtering chamber

· Magnetron sputtering targets

· DC/pulse sputtering power supply

· Auto-matching RF power supply

· Pulse bias power supply

· Sample heating system

· Vacuum & gas delivery systems

· PLC + touchscreen semi-automatic control system

With a compact, host-control integrated design, the system offers user-friendly operation and space efficiency. It is widely adopted in:

· Universities & research institutes for academic and R&D experiments.

· Industrial enterprises for exploratory trials and new product development.

Key Applications:

1. Nanoscale single-layer, multilayer, and composite films.

2. Deposition of diverse films:

o Metallic/Alloy (Ag, Al, Cu, NiCr, etc.)

o Semiconductor/Ceramic/Dielectric (TiO₂, TiN, CrN, ITO, SiO₂, etc.).

3. Flexible deposition modes: Single-target, sequential, or co-sputtering with three targets.

|

Parameter |

Specification |

|

Vacuum Chamber |

Ø500×H420 mm, 304 stainless steel, front-opening design. |

|

Vacuum System |

Hybrid molecular pump + rotary vane pump + high-vacuum valve; digital vacuum gauge. |

|

Ultimate Vacuum |

≤6.0×10⁻⁵ Pa (after 24-hour pumping, no load). |

|

Leak Rate |

≤0.8 Pa/h (pressure rise rate); ≤10 Pa after 12 hours without pumping. |

|

Pumping Speed |

≤15 min (ambient to 5.0×10⁻³ Pa, no load). |

|

Substrate Stage |

Ø150 mm, compatible with various substrate sizes. |

|

Rotation & Heating |

0–20 rpm rotation; heating range: RT–500±1°C (Shimaden PID closed-loop control). |

|

Sputtering Targets |

3× 3-inch permanent magnet co-focal targets (adjustable angle/height); RF/MF/DC compatible (supports magnetic materials); pneumatic shutter. |

|

Deposition Modes |

Independent/sequential/co-sputtering (bottom-up configuration). |

|

Pulse Bias Power |

-1000 V, 1 set. |

|

Film Uniformity |

≤±5% (within Ø100 mm area). |

|

Control System |

PLC + touchscreen HMI (semi-automatic). |

|

Safety Protections |

Alarms and safeguards for water shortage, overcurrent/voltage, circuit faults; logic interlock system. |

|

Dimensions (Main Unit) |

1900(L)×800(W)×1900(H) mm. |

1. Versatility – Supports diverse materials (metals, ceramics, semiconductors) and complex film structures.

2. Precision Control – PID temperature regulation (±1°C) and high film uniformity (±5%).

3. User-Oriented Design – Compact footprint, intuitive interface, and robust safety features.

4. Research-Grade Performance – High vacuum (10⁻⁵ Pa) and flexible sputtering modes ideal for R&D and pilot production.

![]()

![]()

![]()

PACKAGE:

1 Standard exported package: Internal anticollision protection, external export wooden box packaging.

2 Shipping by express, by air, by sea according to customers' requirements to find the most suitable way.

3 Responsible for the damage during the shipping process, will change the damage part for you for free.

DELIVERY TIME: 15-20 days after confirming order,detail delivery date should be decided according to production season and order quantity

ONLINE

ONLINE +86 13174506016

+86 13174506016 Louis@lithmachine.com

Louis@lithmachine.com +86 18559646958

+86 18559646958

18659217588

18659217588