- Language:

English ▼

English ▼

English ▼

English ▼ItemNo :

Lith-BY-JS06MOQ :

1Compliance:

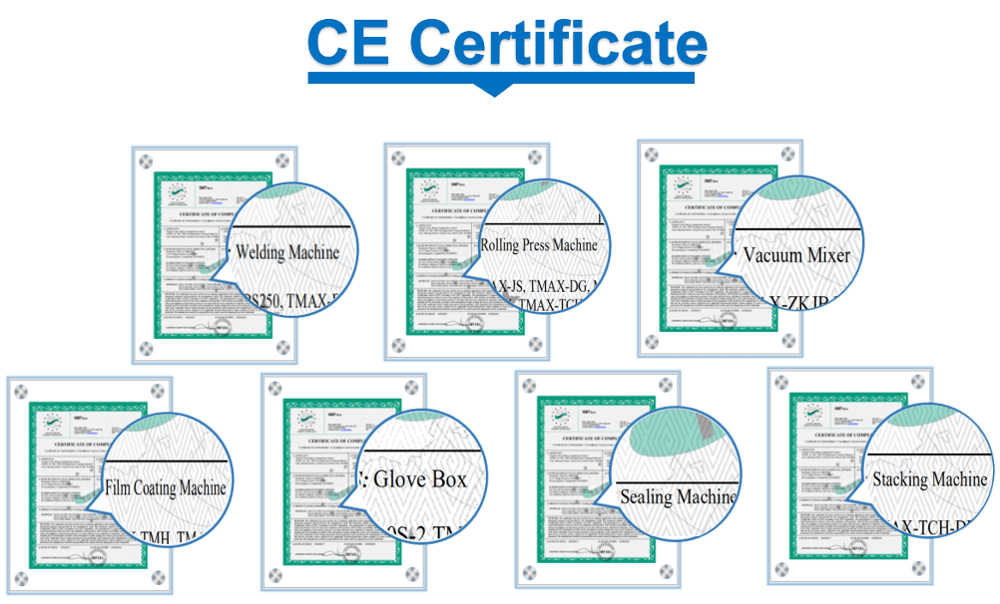

CE CertifiedWarranty:

1 yearDelivery Time:

5 days

Model: Lith-BY-JS06-Benchtop System for R&D and Educational Laboratories

The Lith-BY-JS06 is a compact, cost-effective, high-vacuum magnetron sputtering system designed for pilot-scale experiments in research and educational laboratories. It integrates key components, including a sputtering vacuum chamber, permanent magnet targets (strong/weak magnetic fields), a fiber-optic rotary stage (customizable), DC power supply, gas supply system, pumping system, water cooling system, film thickness monitoring, vacuum measurement, electronic control system, and a sturdy mounting frame.

|

Parameter |

Specification |

|

Sputtering Gas |

Adjustable (e.g., argon, nitrogen, etc., depending on experimental requirements). |

|

Target Material |

Standard: Gold target; Optional: Silver, copper, chromium, etc. |

|

Target Configuration |

50mm (weak magnetic target) / 60mm (strong magnetic target). |

|

Sputtering Current |

0–500mA |

|

Ultimate Vacuum |

≤5×10−4 Pa |

|

Chamber Dimensions |

Diameter: 180mm; Height: 200mm |

|

Sample Stage |

Fiber-optic rotary stage (customizable). |

|

Operating Voltage |

230V, 50Hz |

· Ideal for: Biological specimens, polymers, and other beam-sensitive materials.

· Advantage: In SEM imaging, high-energy electron beams can cause thermal damage to delicate samples. A thin sputtered conductive coating (e.g., gold or carbon) acts as a protective layer, preserving sample integrity while enhancing imaging quality.

· Ideal for: Insulating materials (e.g., ceramics, glass, or organic compounds).

· Advantage: Non-conductive samples accumulate surface charges ("charging effect") under electron beams, distorting SEM images. A sputtered conductive metal layer (e.g., gold or platinum) dissipates charges, eliminating artifacts and improving signal-to-noise ratio for clearer imaging.

· Ideal for: Novel materials requiring conductive electrodes for electrical property analysis.

· Advantage: Enables precise deposition of thin conductive films for experimental electrode fabrication, facilitating studies on material conductivity.

![]()

![]()

![]()

PACKAGE:

1 Standard exported package: Internal anticollision protection, external export wooden box packaging.

2 Shipping by express, by air, by sea according to customers' requirements to find the most suitable way.

3 Responsible for the damage during the shipping process, will change the damage part for you for free.

DELIVERY TIME: 15-20 days after confirming order,detail delivery date should be decided according to production season and order quantity

ONLINE

ONLINE +86 13174506016

+86 13174506016 Louis@lithmachine.com

Louis@lithmachine.com +86 18559646958

+86 18559646958

18659217588

18659217588