- Language:

English ▼

English ▼

English ▼

English ▼ItemNo :

Lith-BY-JS05MOQ :

1Compliance:

CE CertifiedWarranty:

1 yearDelivery Time:

5 days

Model: Lith-BY-JS05 – Product Specifications

1. System Overview

The Lith-BY-JS05 is a compact, benchtop magnetron sputtering system designed for high-performance thin-film deposition in research and laboratory environments. Featuring a dual-target configuration, it supports the deposition of single or multilayer functional films, including conductive, dielectric, optical, and hard coatings. The system combines high vacuum performance, precise process control, and user-friendly operation, making it ideal for material science, semiconductor research, and advanced coating development.

|

Parameter |

Specification |

|

Model |

Lith-BY-JS05 |

|

Type |

Benchtop Laboratory System |

|

Dimensions (W×D×H) |

610 × 420 × 490 mm |

|

Weight |

100 kg |

|

Power Supply |

AC 220V 50Hz / 110V 60Hz |

|

Power Consumption |

<3 kW |

|

Cooling Method |

Water-cooled (target) + Air-cooled (pump) |

|

Warranty |

1 year limited (lifetime support) |

|

Parameter |

Specification |

|

Pump Configuration |

Rotary Pump (4.4 L/s) + Turbo Pump (300 L/s) |

|

Base Pressure |

≤5×10⁻⁵ Pa |

|

Working Pressure |

0.5–5 Pa |

|

Pump-Down Time (to 10⁻³ Pa) |

≤10 minutes |

|

Vacuum Measurement |

Full-range gauge (Atmosphere to 10⁻⁵ Pa) |

|

Parameter |

Specification |

|

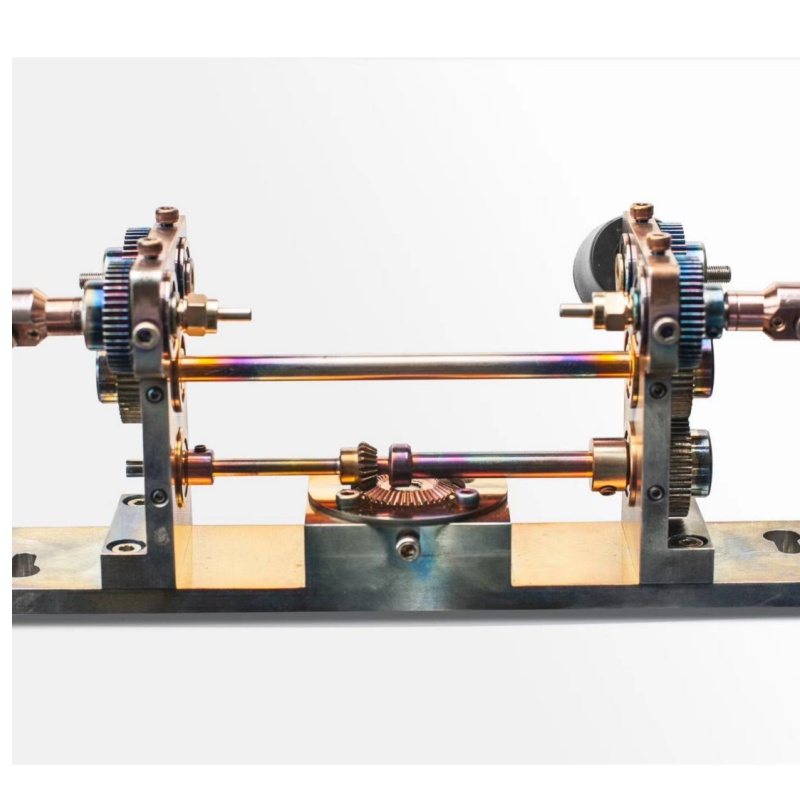

Target Configuration |

Dual magnetron targets (independent control) |

|

Target Size |

Ø50 × 3 mm (standard: Cu & Al) |

|

Target Materials |

Metals, alloys, oxides, ceramics |

|

Magnetic Compatibility |

Weak magnetic materials supported |

|

Deposition Rate |

Adjustable (process-dependent) |

|

Parameter |

Specification |

|

Gas Flow Control |

Mass flow controller (Ar/other inert gases) |

|

Power Supply |

DC: 0–600V, 0–1.6A; RF: 300W/500W (optional) |

|

Thickness Monitoring |

Real-time touchscreen control with 257 preloaded materials |

|

Operation Interface |

Dual-screen control system |

|

Parameter |

Specification |

|

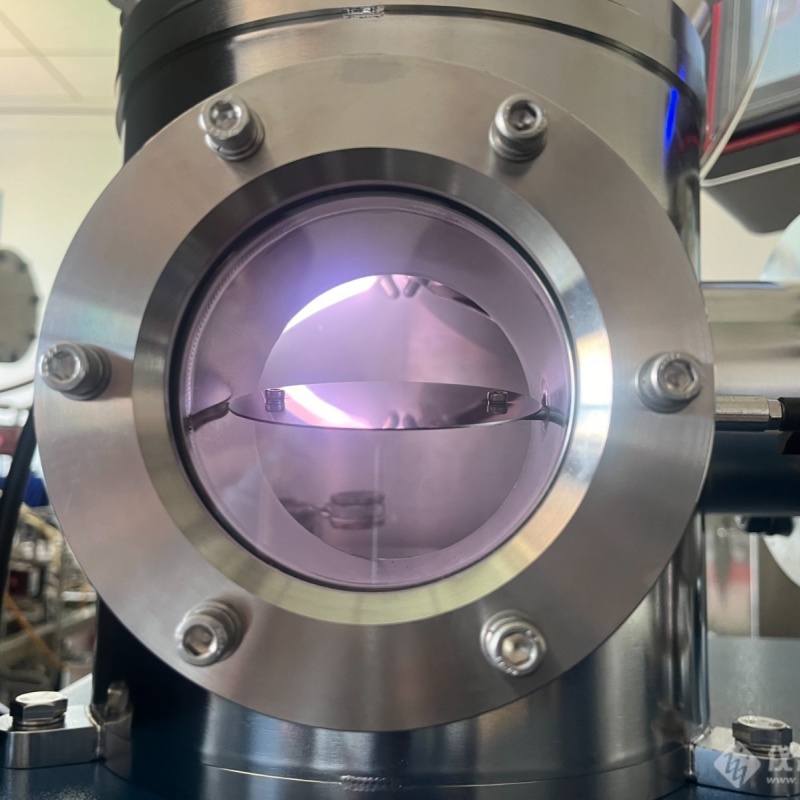

Chamber Material |

Stainless steel |

|

Chamber Dimensions |

Outer: Ø260 × 500 mm; Inner: Ø210 × 270 mm |

|

Substrate Holder |

Customizable (max Ø200 mm) |

· Dual-Target Flexibility: Enables co-deposition or sequential layering of dissimilar materials (e.g., metal/oxide stacks).

· High Vacuum Performance: Achieves 5×10⁻⁵ Pa base pressure for contamination-free films.

· Precision Control: Touchscreen interface with real-time thickness monitoring and gas flow regulation.

· Compact Design: Optimized for small labs with limited space.

· Material Versatility: Supports metals, oxides, polymers, and magnetic materials.

![]()

![]()

![]()

PACKAGE:

1 Standard exported package: Internal anticollision protection, external export wooden box packaging.

2 Shipping by express, by air, by sea according to customers' requirements to find the most suitable way.

3 Responsible for the damage during the shipping process, will change the damage part for you for free.

DELIVERY TIME: 15-20 days after confirming order,detail delivery date should be decided according to production season and order quantity

ONLINE

ONLINE +86 13174506016

+86 13174506016 Louis@lithmachine.com

Louis@lithmachine.com +86 18559646958

+86 18559646958

18659217588

18659217588