- Language:

English ▼

English ▼

English ▼

English ▼ItemNo :

Lith-BY-JS10MOQ :

1Compliance:

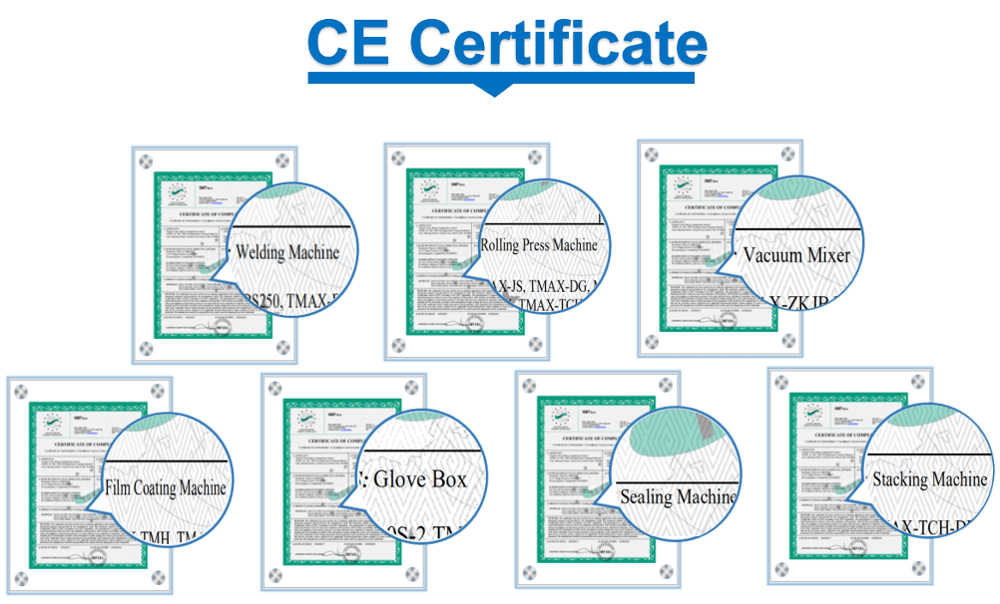

CE CertifiedWarranty:

1 yearDelivery Time:

5 days

Model: Lith-BY-JS10 – Product Specifications

| Parameter | Specification |

|---|---|

| Model Number | Lith-BY-JS10 |

| Vacuum Pump | Oil-required Rotary Vacuum Pump (Explicit oil filling needed) |

| Pumping Speed | 50Hz: 16 m³/h (4.4 L/s) • 60Hz: 19.2 m³/h (5.2 L/s) • 20% speed boost at 60Hz |

| Ultimate Vacuum | 2 Pa |

| Max Sputtering Current | 1.6A |

| Operating Pressure Range | 20 Pa – 8 Pa |

| Pump-Down Time | <5 min (to 2 Pa) |

| Vacuum Measurement Range | Atmospheric pressure to 2×10⁷ mbar |

| Gas Control System | Precision Gas Flow Controller |

| Chamber Specifications | Ø350 × 240mm (H) • Scratch-resistant quartz glass viewport |

| Target Specifications | Ø200mm • Materials: Au, Ag, Pt, Cu (noble/conductive metals) |

| Operation | Instruction manual guided |

| Dimensions/Weight | 490(L) × 400(W) × 590(H) mm • 70 kg |

| Power Requirements | Dual-voltage: AC 110V/60Hz (Americas) or AC 220V/50Hz (Europe/Asia) |

| Power Consumption | <1500W |

| Warranty & Support | 1-year limited warranty + lifetime technical support |

![]()

![]()

![]()

PACKAGE:

1 Standard exported package: Internal anticollision protection, external export wooden box packaging.

2 Shipping by express, by air, by sea according to customers' requirements to find the most suitable way.

3 Responsible for the damage during the shipping process, will change the damage part for you for free.

DELIVERY TIME: 15-20 days after confirming order,detail delivery date should be decided according to production season and order quantity

ONLINE

ONLINE +86 13174506016

+86 13174506016 Louis@lithmachine.com

Louis@lithmachine.com +86 18559646958

+86 18559646958

18659217588

18659217588