- Language:

English ▼

English ▼

English ▼

English ▼ItemNo :

Lith-PD-JS02MOQ :

1Compliance:

CE CertifiedWarranty:

1 yearDelivery Time:

5 days

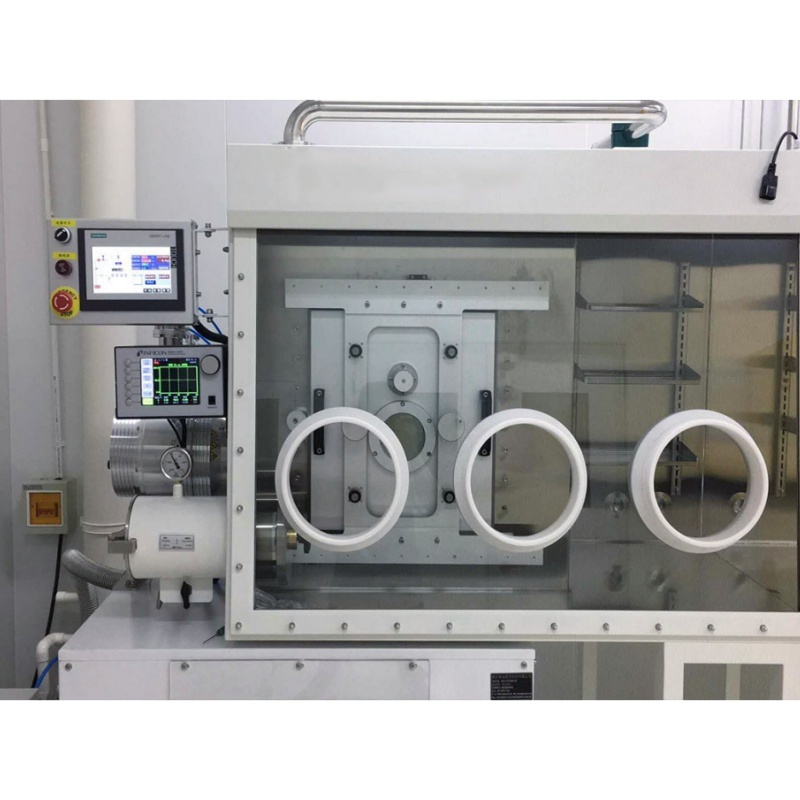

Model: Lith-PD-JS02-PVD Magnetron Sputtering System

Product Overview

The Lith-PD-JS02 High-Vacuum Magnetron Sputtering System is a specialized R&D equipment designed for cutting-edge applications in perovskite solar cells, OLEDs, lithium batteries, quantum dot LEDs, OPVs, and other advanced industries. It enables the deposition of nanoscale oxide, nitride, and metallic thin films. The system integrates seamlessly with glovebox environments, ensuring anhydrous/oxygen-free conditions for the entire process—from spin-coating and sputtering to testing—via a hardware-coupled PVD and glovebox system.

1. Low-Pressure Sputtering Technology (Optional)

1. Delivers dense thin films with minimal substrate damage.

2. High-Precision Chamber Design

1. SUS304 stainless steel sputtering chamber with mirror-polished interior (including shielding plates) for ultra-clean conditions and optimal vacuum performance.

3. Flexible Control Options

1. Manual/Auto Control: Siemens PLC + touchscreen interface.

2. Fully Automated: PC + PLC integration.

|

Parameter |

Details |

|

Overall Dimensions (L×W×H) |

1100 × 800 × 1900 mm |

|

Chamber Dimensions (L×W×H) |

440 × 440 × 450 mm |

|

Substrate Stage |

Max. temperature: 500°C (±1°C accuracy) |

|

Ultimate Vacuum |

2 × 10−5 Pa |

|

Pumping Speed & Hold |

≤8 × 10−4 Pa in 20 min; ≤5 Pa over 12 hours |

|

Deposition Uniformity |

±3% to ±5% across the tray |

|

Target Options |

Rectangular: 210×210 mm / 300×300 mm; Circular targets available |

Ideal For:

· Research & Prototyping: Tailored for sensitive materials requiring inert environments (e.g., perovskites, OLED layers).

· Multi-Process Integration: Combines sputtering, spin-coating, and testing in a single glovebox workflow, minimizing contamination risks.

· High-Quality Films: Superior uniformity and low-defect deposition critical for optoelectronic and energy storage devices.

Why Choose This System?

· Glovebox Compatibility: Unique airtight integration for oxygen/moisture-sensitive processes.

· Versatile Configurations: Supports diverse target geometries and automation levels.

· Industry-Grade Precision: Tight temperature control (±1°C) and high vacuum stability ensure reproducible results.

![]()

![]()

![]()

PACKAGE:

1 Standard exported package: Internal anticollision protection, external export wooden box packaging.

2 Shipping by express, by air, by sea according to customers' requirements to find the most suitable way.

3 Responsible for the damage during the shipping process, will change the damage part for you for free.

DELIVERY TIME: 15-20 days after confirming order,detail delivery date should be decided according to production season and order quantity

ONLINE

ONLINE +86 13174506016

+86 13174506016 Louis@lithmachine.com

Louis@lithmachine.com +86 18559646958

+86 18559646958

18659217588

18659217588