- Language:

English ▼

English ▼

English ▼

English ▼ItemNo :

Lith-HZ-JS04MOQ :

1Compliance:

CE CertifiedWarranty:

1 yearDelivery Time:

5 days

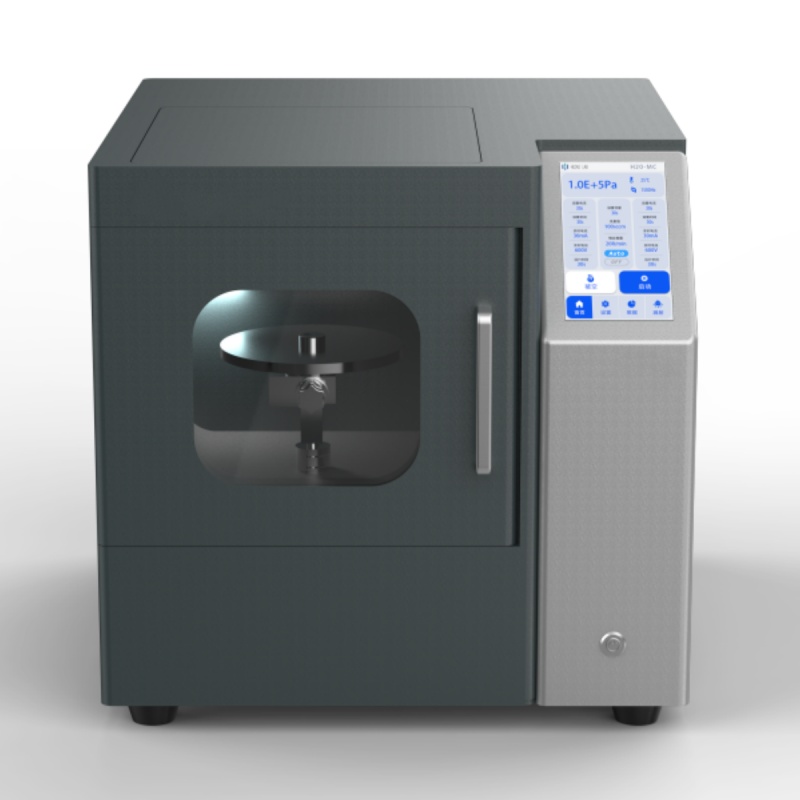

Model: Lith-HZ-JS04- High-Vacuum Dual-Target Sputtering Coater

Technical Parameters

|

Category |

Specification |

|

Model |

Lith-HZ-JS04 |

|

Vacuum System |

Oil-free diaphragm pump + molecular pump |

|

Ultimate Vacuum |

≤1.0×10⁻⁴ Pa |

|

Pressure Measurement |

Full-range cold cathode gauge + front-end Pirani gauge |

|

Gas Control |

MFC (Mass Flow Controller) for Ar/O₂/N₂ |

|

Target Configuration |

Dual targets (independent control, alternate/synchronous sputtering) |

|

Target Compatibility |

Metals, alloys, compounds (custom sizes available) |

|

Optional Feature |

Real-time thickness monitoring (nanometer precision) |

|

Cooling System |

Energy-efficient target cooling |

|

Safety Protections |

Overpressure/overcurrent/overheat protection, vacuum interlock, emergency vent |

1. Dual-Target Flexibility

·Enables multi-material deposition (e.g., bilayers, graded films, or interfaces) in a single run.

2. High-Vacuum Precision

·Ultra-low base pressure (≤1.0×10⁻⁴ Pa) minimizes contamination for high-purity films.

3. Intelligent Process Control

·MFC-regulated gas flow ensures repeatable reactive sputtering (e.g., oxides/nitrides).

4. User-Optimized Design

·Energy-saving pumps and cooling reduce operational costs without compromising performance.

· Semiconductors: Electrode/metallization layers, barrier films.

· Optics: Anti-reflective, conductive, or hard coatings.

· Energy: Thin-film batteries, solar cell layers.

· Research: Nanomaterials, heterostructures, surface engineering.

· Lab to Production: Scalable for both R&D prototyping and industrial batch processing.

· Safety & Reliability: Automated safeguards protect equipment and users.

· Customizable: Adaptable to diverse materials and film architectures.

![]()

![]()

![]()

PACKAGE:

1 Standard exported package: Internal anticollision protection, external export wooden box packaging.

2 Shipping by express, by air, by sea according to customers' requirements to find the most suitable way.

3 Responsible for the damage during the shipping process, will change the damage part for you for free.

DELIVERY TIME: 15-20 days after confirming order,detail delivery date should be decided according to production season and order quantity

ONLINE

ONLINE +86 13174506016

+86 13174506016 Louis@lithmachine.com

Louis@lithmachine.com +86 18559646958

+86 18559646958

18659217588

18659217588