- Language:

English ▼

English ▼

English ▼

English ▼ItemNo :

Lith-SD-01MOQ :

1Compliance:

CE CertifiedWarranty:

1 yearDelivery Time:

5 days

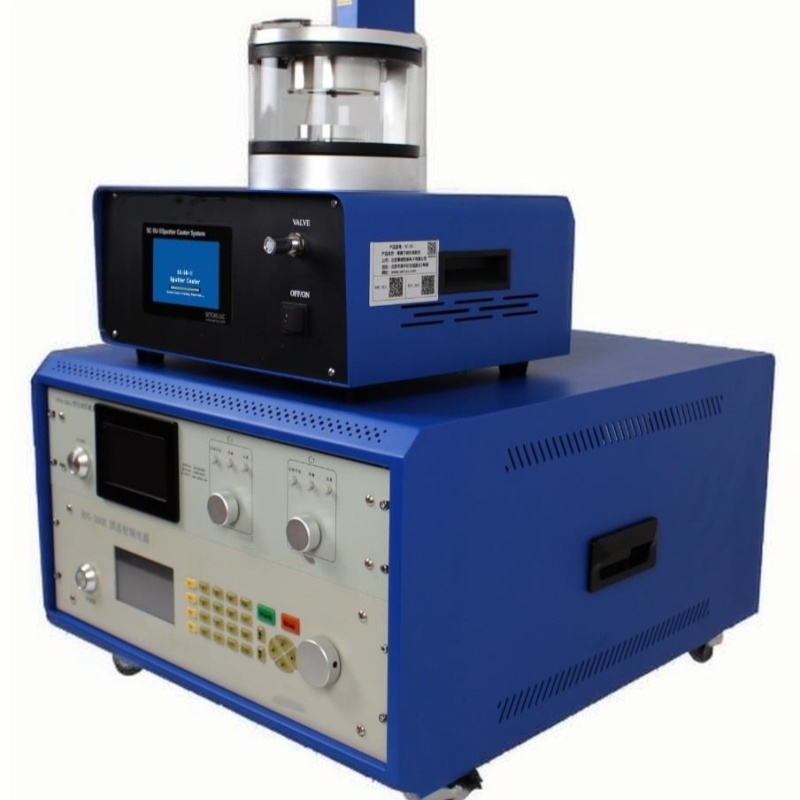

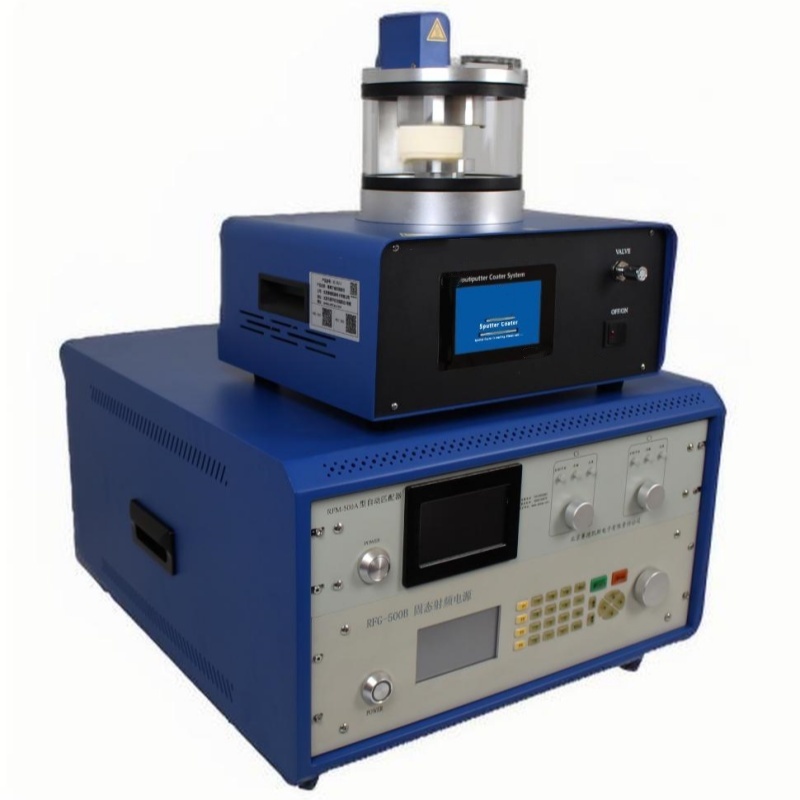

Model: Lith-SD-01-Metals & Non-Metals: Insulators, Semiconductors, Carbon-Based Thin Film Deposition

Product Specifications

|

Parameter |

Specification |

|

Model |

Lith-SD-01 |

|

Type |

RF Magnetron Sputtering System |

|

Chamber Size |

150 × 120 mm |

|

Target Material |

50 mm diameter (metals & non-metals, thickness: 1–2 mm) |

|

RF Power |

Adjustable (1–500 W) |

|

RF Frequency |

13.56 MHz |

|

Matching Network |

Automatic impedance matcher |

|

Sputtering Area |

50 mm |

|

Ultimate Vacuum |

5 Pa (base pressure) |

|

Process Gases |

Argon, nitrogen, and other inert gases (flow rate adjustable) |

|

Max. Deposition Rate |

8 nm/min |

· RF Power & Auto-Matching: 13.56 MHz RF with automatic impedance matching ensures stable sputtering of both conductive and insulating materials (e.g., oxides, ceramics).

· Broad Applications: Ideal for advanced thin-film research in semiconductors, optics, and functional coatings.

· Adjustable Inert Gas Flow: Supports Ar, N₂, and other inert gases for controlled deposition environments.

· High Purity Deposition: Base vacuum of 5 Pa minimizes contamination, ensuring high-quality film growth.

· Quick Target Change: Compatible with 50 mm targets (1–2 mm thick) for flexible material testing.

· Preset Process Recipes: Saves and recalls parameters for repeatable experiments and production.

· Max Deposition Rate: 8 nm/min with excellent film uniformity.

· Automated Matching: Reduces manual tuning and enhances process stability.

✔ Research & Development: Thin-film studies for semiconductors, dielectrics, and optical coatings.

✔ Small-Scale Production: Prototyping and specialized coating applications.

✔ Multi-Material Sputtering: Supports both metallic and non-metallic targets for diverse material systems.

![]()

![]()

![]()

PACKAGE:

1 Standard exported package: Internal anticollision protection, external export wooden box packaging.

2 Shipping by express, by air, by sea according to customers' requirements to find the most suitable way.

3 Responsible for the damage during the shipping process, will change the damage part for you for free.

DELIVERY TIME: 15-20 days after confirming order,detail delivery date should be decided according to production season and order quantity

ONLINE

ONLINE +86 13174506016

+86 13174506016 Louis@lithmachine.com

Louis@lithmachine.com +86 18559646958

+86 18559646958

18659217588

18659217588