- Language:

English ▼

English ▼

English ▼

English ▼ItemNo :

Lith-TK-JS01MOQ :

1Compliance:

CE CertifiedWarranty:

1 yearDelivery Time:

5 days

Model: Lith-TK-JS01-Multilayer Thin Film Fabrication

Technical Parameters

|

Parameter |

Specification |

|

Model |

TK-JS01 |

|

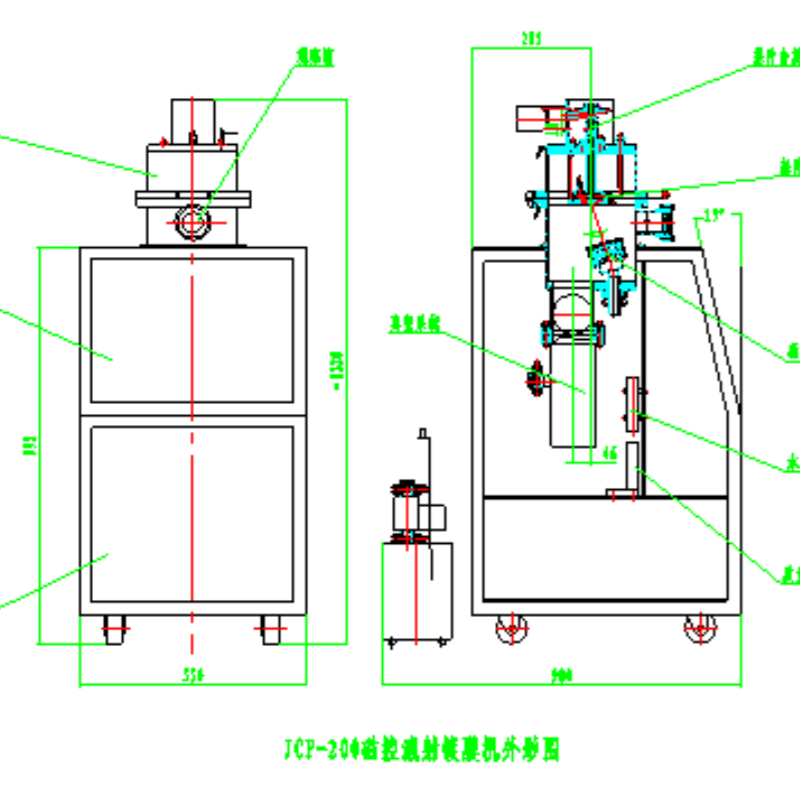

Vacuum Chamber Structure |

Vertical top-opening design, manual gas spring lift |

|

Chamber Dimensions |

Φ220mm × H300mm |

|

Heating Temperature |

Room temperature to 500°C |

|

Substrate Holder Size |

Φ100mm (rotatable, heated) |

|

Film Uniformity |

≤ ±5.0% within Φ50mm area |

|

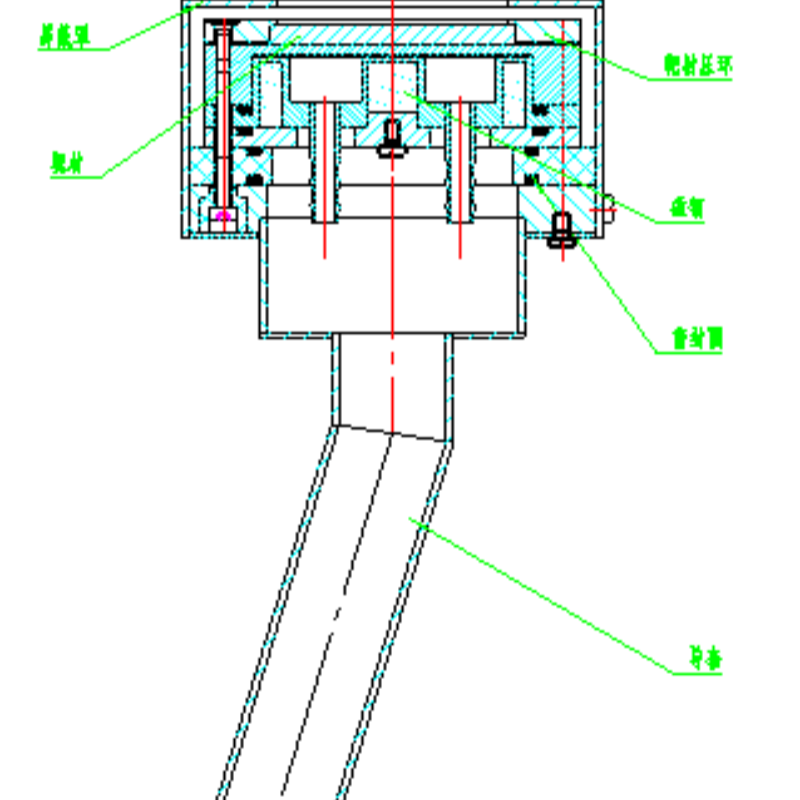

Sputtering Target |

1 × Φ2-inch magnetron target (DC/RF compatible) |

|

Process Gas Control |

1–2 channels, precision ±0.1 sccm |

|

Control System |

PLC + touchscreen interface |

|

Footprint (Main Unit) |

600mm (L) × 800mm (W) × 1700mm (H) |

|

Power Consumption |

≥6 kW |

|

Base Vacuum |

6.6×10⁻⁵Pa |

|

Pumping Time |

≤15 min (from atmosphere to 7×10⁻³Pa) |

Designed for thin-film research and small-batch production, ideal for:

· Academic labs: Universities and research institutes studying novel materials.

· Industrial R&D: Prototyping functional coatings (e.g., ITO for solar cells, wear-resistant alloys).

1. Multi-Mode Sputtering

·Supports DC, RF, and pulsed sputtering for metals, oxides, and semiconductors.

·Single-/multi-target configurations for layered or composite films.

2. User-Friendly Operation

·Automated PLC control with real-time monitoring via touchscreen.

·Substrate heating (≤300°C) and rotation (2–20 rpm) for uniform coatings.

3. Compact & Reliable

·Minimal footprint, low maintenance, and energy-efficient design.

4. Safety & Precision

·Water-cooling protection, gas flow control (±0.1 sccm), and arc suppression.

1. Installation:

·Ensure stable power (AC 380V ±5%, ≥8 kW), cooling water (≥10 L/min), and proper grounding (<3Ω).

·Verify vacuum seals and gas connections before startup.

2. Operational Workflow:

·Pumping: Start mechanical pump → Open foreline valve → Activate molecular pump (at >5 Pa).

·Deposition: Set substrate temperature → Adjust gas flow → Initiate sputtering (5–15 W/cm² target power).

·Shutdown: Cool substrate (<50°C) → Vent chamber → Maintain pump oil/clean seals regularly.

3. Maintenance Tips:

·Replace mechanical pump oil every 500 operational hours.

·Clean chamber and target surfaces after each use to avoid cross-contamination.

This combines research-grade precision with industrial durability, offering:

· Flexibility: Adaptable to diverse materials (metals, dielectrics, etc.).

· Efficiency: Fast pumping, intuitive controls, and low running costs.

· Support: Comprehensive manuals and technical assistance provided.

For advanced applications (e.g., perovskite layers), consult the manufacturer for tailored process parameters.

![]()

![]()

![]()

PACKAGE:

1 Standard exported package: Internal anticollision protection, external export wooden box packaging.

2 Shipping by express, by air, by sea according to customers' requirements to find the most suitable way.

3 Responsible for the damage during the shipping process, will change the damage part for you for free.

DELIVERY TIME: 15-20 days after confirming order,detail delivery date should be decided according to production season and order quantity

ONLINE

ONLINE +86 13174506016

+86 13174506016 Louis@lithmachine.com

Louis@lithmachine.com +86 18559646958

+86 18559646958

18659217588

18659217588