- Language:

English ▼

English ▼

English ▼

English ▼ItemNo :

Lith-PC-JS04MOQ :

1Compliance:

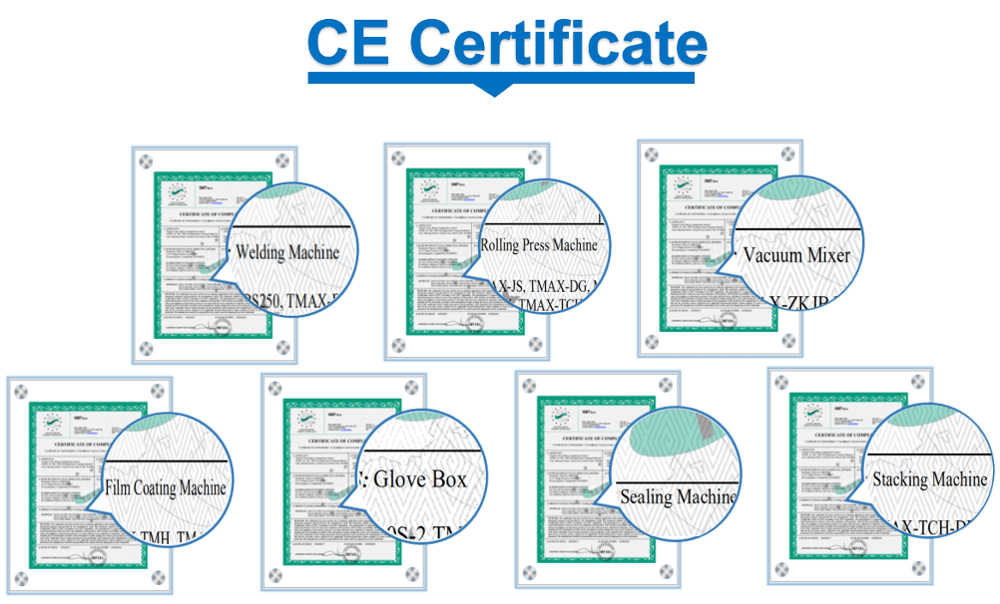

CE CertifiedWarranty:

1 yearDelivery Time:

5 days

Model: Lith-PC-JS04-Multilayer Thin-Film Fabrication

|

Parameter |

Specification |

|

Base Vacuum |

6.7×10−5 Pa |

|

Operating Vacuum (after 1h) |

≤4×10−4 Pa |

|

Magnetron Targets |

3 (3-inch, permanent magnet, water-cooled, side shutters) |

|

Target-to-Substrate Distance |

120–200 mm (manually adjustable, scale-indicated) |

|

Target Tilt Angle |

0–45° |

|

Substrate Heating |

Iodine-tungsten lamp, max 400°C |

|

Substrate Size |

Φ60 mm (single-piece) |

|

Substrate Rotation |

0–50 RPM (motorized) |

|

Bias Voltage |

0–200 V (adjustable) |

|

Gas Flow Control |

2-channel MFC, 0–50 sccm range |

|

Control Functions |

Manual heating/rotation/shutter/vacuum monitoring |

· Adjustable target-substrate geometry for tailored film stress and uniformity.

· Three-target co-sputtering enables multilayer/composite films (e.g., superlattices).

· UHV-compatible chamber minimizes impurities for high-purity films.

· Heated substrate (400°C max) improves crystallinity (e.g., for oxides/semiconductors).

· Benchtop design suits small-batch R&D and material screening.

· Protective coatings (e.g., TiN, DLC for tools).

· Transparent conductive films (e.g., ITO, AZO).

· MEMS/sensor fabrication.

Best for: Labs requiring flexible, high-precision thin-film deposition with manual control.

![]()

![]()

![]()

PACKAGE:

1 Standard exported package: Internal anticollision protection, external export wooden box packaging.

2 Shipping by express, by air, by sea according to customers' requirements to find the most suitable way.

3 Responsible for the damage during the shipping process, will change the damage part for you for free.

DELIVERY TIME: 15-20 days after confirming order,detail delivery date should be decided according to production season and order quantity

ONLINE

ONLINE +86 13174506016

+86 13174506016 Louis@lithmachine.com

Louis@lithmachine.com +86 18559646958

+86 18559646958

18659217588

18659217588