- Language:

English ▼

English ▼

English ▼

English ▼ItemNo :

Lith-PC-JS11MOQ :

1Compliance:

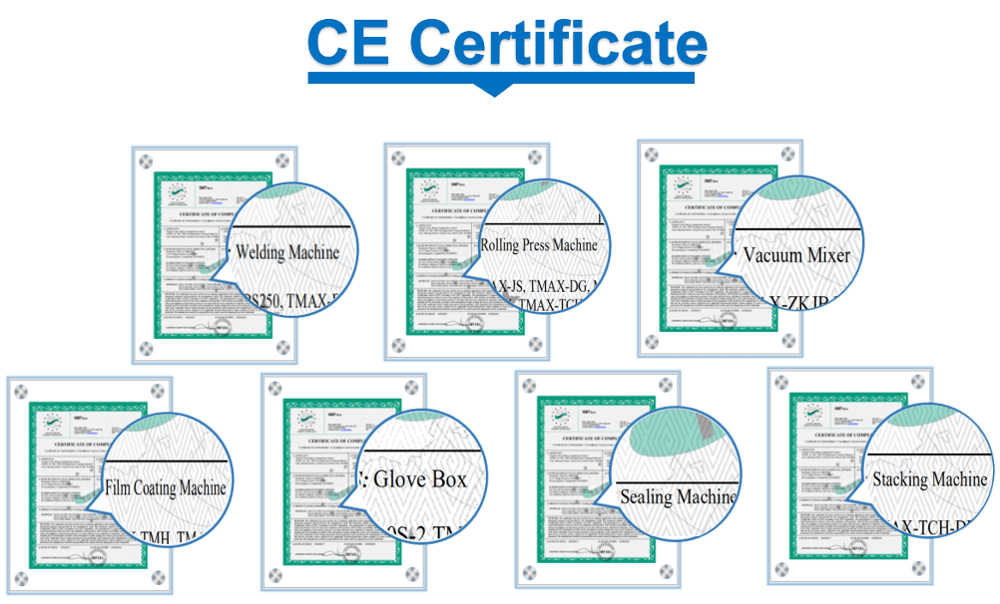

CE CertifiedWarranty:

1 yearDelivery Time:

5 days

Model: Lith-PC-JS11 – Product Specifications

Specifications

| Category | Parameter | Details |

|---|---|---|

| Vacuum Performance | Ultimate Vacuum (Sputtering Chamber) | ≤6.6×10⁻⁶ Pa |

| System Leak Rate | ≤5.0×10⁻⁷ Pa·L/S | |

| Pump-Down Time (Atmosphere → 6.6×10⁻⁴ Pa) | ≤30 min | |

| Vacuum Retention (After 12 Hours Shutdown) | ≤5 Pa | |

| Sputtering Chamber | Structure | Vertical, top-opening, stainless steel (argon-welded, electropolished) |

| Dimensions | ≥Ø300 mm × 300 mm (with anti-contamination liner) | |

| Bakeability & Sealing | 100–150°C; metal gasket/fluororubber O-ring | |

| Magnetron Sputtering | Target Configuration | 3 × 50 mm adjustable-angle permanent magnet targets (RF/DC/MF compatible) |

| Power Supply | 2 × DC (≥500 W), 1 × auto-matching RF (≥500 W) | |

| Film Uniformity | ≤5% deviation | |

| Additional Features | 3 × SMC rotary shutters; magnetic material support | |

| Substrate Stage | Sample Capacity | 1 × ≥100 mm diameter |

| Rotation Speed | 0–30 RPM (adjustable) | |

| Heating Range | RT–500°C (PID-controlled, thermocouple feedback) | |

| Gas Delivery | Mass Flow Control | 2 paths (100 SCCM + 20 SCCM MFCs, CF16 valves) |

| Auxiliary Gas Lines | 2 × DN16 inlet valves | |

| Pumping System | High-Vacuum Pump | Pfeiffer Hipace 700 (680 L/s) + 4 L/s rotary pump |

| Valves & Pipeline | DN40/CC150 pneumatic valves, stainless steel bellows | |

| Control & Safety | Automation | PLC + industrial PC + touchscreen (real-time monitoring/logging) |

| Protection | Interlocks for water/power faults (overcurrent, open circuit, etc.) | |

| Additional Components | Frame | Steel construction, lockable casters, removable panels |

| Included Accessories | Chiller, silent compressor, tool kit, spare parts | |

| Measurement | Vacuum Gauge | INFICON combination gauge |

![]()

![]()

![]()

PACKAGE:

1 Standard exported package: Internal anticollision protection, external export wooden box packaging.

2 Shipping by express, by air, by sea according to customers' requirements to find the most suitable way.

3 Responsible for the damage during the shipping process, will change the damage part for you for free.

DELIVERY TIME: 15-20 days after confirming order,detail delivery date should be decided according to production season and order quantity

ONLINE

ONLINE +86 13174506016

+86 13174506016 Louis@lithmachine.com

Louis@lithmachine.com +86 18559646958

+86 18559646958

18659217588

18659217588