ItemNo :

LITH-LFT300MOQ :

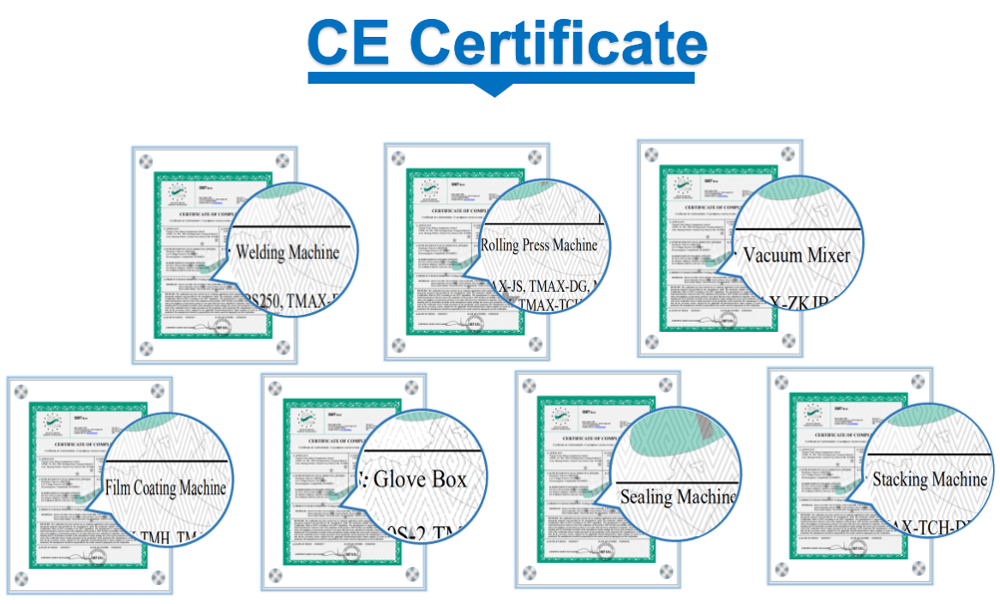

1Compliance:

CE CertifiedWarranty:

2 yearsDelivery Time:

5 days

Introduction

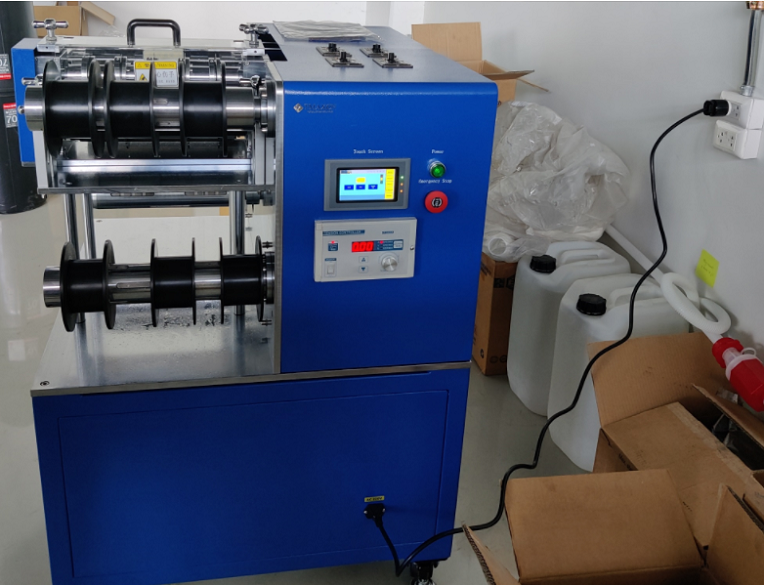

Two or more continuous slitting process of roll-shaped material is adopted. The equipment is equipped with a precision knife holder, which can realize extremely high-precision foil slitting, and is widely used in lithium battery, metal foil, optical film and other functional film industries.

Main features

*Ultra-fine tungsten steel blade, good cutting quality and long service life;

*The slitting width has high precision, and the finished product has no burrs, waves, and indentations;

*The amount of knife can be adjusted, and the ratio of knife speed to material linear speed can be adjusted;

*By adjusting the angle of feeding and discharging materials, it can be adapted to the slitting of materials of different materials and thickness values;

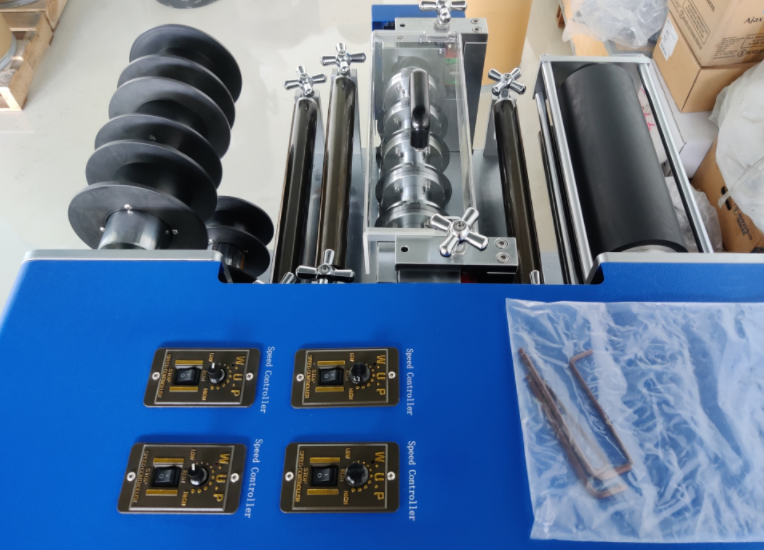

*Single vertical board structure, independent knife holder, equipped with dust removal device;

*Upper and lower round knife structure, the slitting width can be adjusted by replacing the spacer;

*The winding tension is automatically controlled, and the upper and lower shafts are independently adjustable within 50N;

*PLC control, HMI operation, convenient and easy to use;

Specifications

|

Slitting method |

Single-piece rolling |

|

Cutter type |

Upper and lower round knives for cutting |

|

Width adjustment |

Change separator adjustment |

|

Cutting thickness |

100-300um |

|

Slitting blade |

Ultrafine alloy tungsten steel, diameter 100mm |

|

Slitting width |

20-300mm |

|

Burr condition |

≤25um |

|

Amount of the knife |

0.2-0.4mm adjustable, dial indicator display |

|

Slitting speed |

Max. 4m/min |

|

Power supply |

Voltage single-phase 220V AC±10%, frequency 50Hz/60Hz, power 1kW |

|

Environment |

Recommended environment temperature is 25±3℃, humidity is 30~90RH, no vibration and electromagnetic interference |

|

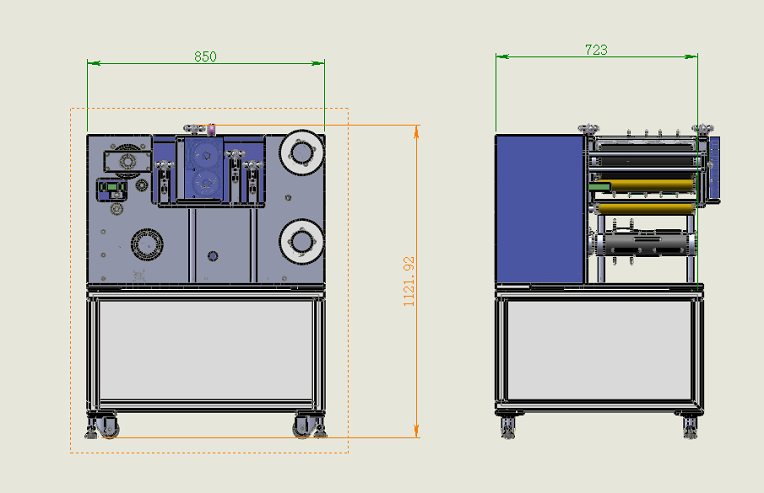

Dimensions |

L900mm*W980mm*H450mm |

|

Weight |

About 100kg |

![]()

Power Processing→Power Grinding→Vacuum Mixing→Electrode Coating→Roll Press→Sheet Cutting→Vacuum Drying→Ultrasonic Welding→Electrode Winding→Spot Welding→Grooving→Glove Box→Electrolyte Injection→Electrode Diffusion→Hydraulic Sealing→Battery Analyzer

Related Machine

|

|

|

|

|

|

Electrode Slitting |

Welding Power: 80-6500W optional |

Lab cylindrical cell grooving machine |

Manual Sealing or Pneumatic Sealing Machine |

8 Channel Battery Tester

|

![]()

![]()

![]()

PACKAGE:

1 Standard exported package: Internal anticollision protection, external export wooden box packaging.

2 Shipping by express, by air, by sea according to customers' requirements to find the most suitable way.

3 Responsible for the damage during the shipping process, will change the damage part for you for free.

DELIVERY TIME:15-20 days after confirming order,detail delivery date should be decided according to production season and order quantity

ONLINE

ONLINE +86 13174506016

+86 13174506016 Louis@lithmachine.com

Louis@lithmachine.com +86 18559646958

+86 18559646958

18659217588

18659217588