- Language:

English ▼

English ▼

English ▼

English ▼ItemNo :

LITH-GYJ-200-300MOQ :

1Compliance:

CE CertifiedWarranty:

2 yearsDelivery Time:

5 days

Features

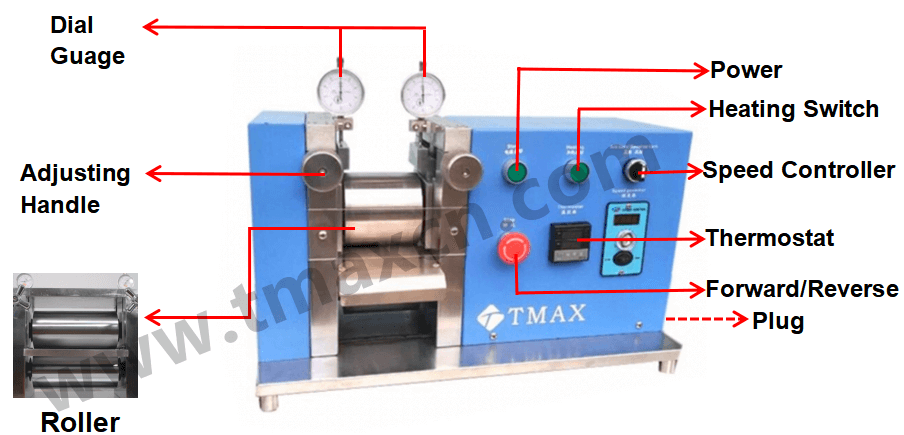

LITH-DG is a UL/CSA ready electric rolling press with variable speed 24DC gear motor and UL certified switch power supply, which can be used from 110V- 220VAC under Argon gas glovebox. It has dual rollers and is an ideal rolling press for preparing electrode sheet for Li-Ion batteries research after coating and drying.

Specifications

|

Model |

DG100L |

DG150L |

DG200L |

DG250L |

DG300L |

DG330L |

GY200W |

|

Roller Dimensions |

96mm(Dia.) x 100mm(W) |

96mm(Dia.) x 150mm(W) |

96mm(Dia.) x 200mm(W) |

96mm(Dia.) x 250mm(W) |

96mm(Dia.) x 300mm(W) |

96mm(Dia.) x 330mm(W) |

200mm(Dia.) x 200mm(W) |

|

Working Voltage |

110V - 240V AC, 50/60Hz, automatic switch for worldwide use |

||||||

|

Structure |

Heavy duty steel frame, gears, and handle |

||||||

|

Roller |

1. Roller diameter tolerance: 0.004mm |

||||||

|

Roller Surface Hardness |

62 HRC |

||||||

|

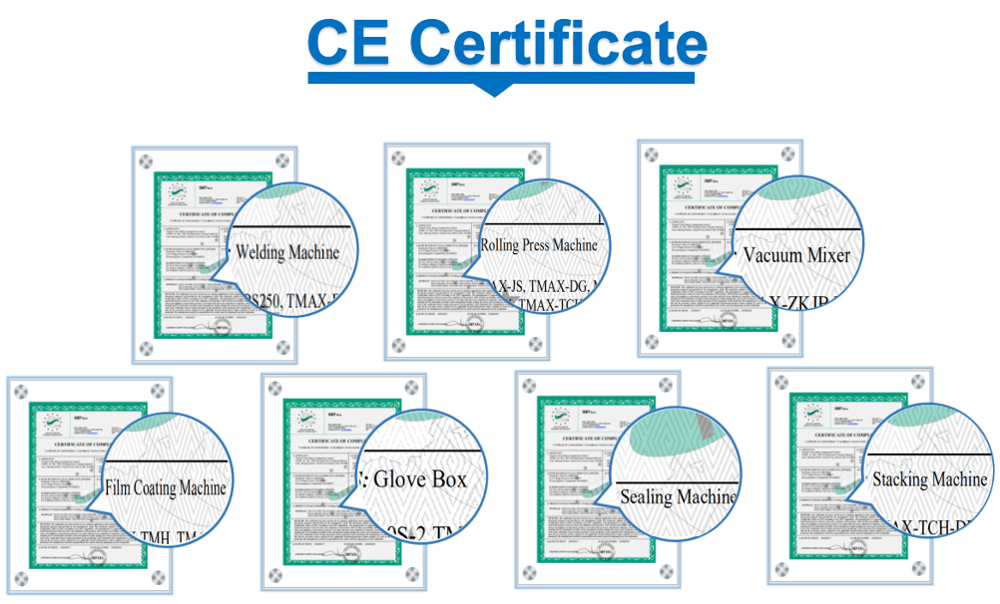

Compliance |

CE Certificate |

||||||

|

Warranty |

Two Years limited warranty with lifetime support |

||||||

|

Warnings |

1. Never roll materials with hardness > 50HRC |

||||||

![]()

Power Processing→Power Grinding→Vacuum Mixing→Electrode Coating→Roll Press→Sheet Cutting→Vacuum Drying→Ultrasonic Welding→Electrode Winding→Spot Welding→Grooving→Glove Box→Electrolyte Injection→Electrode Diffusion→Hydraulic Sealing→Battery Analyzer

Related Machine

Electrode Slitting

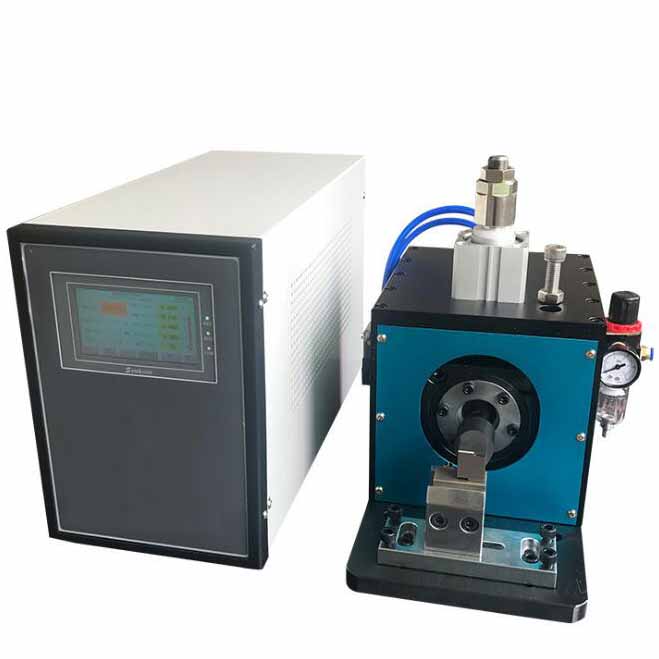

Welding Power:

80-6500W optional

Lab cylindrical cell grooving machine

Manual Sealing or Pneumatic Sealing Machine

8 Channel Battery Tester

![]()

![]()

![]()

PACKAGE:

1 Standard exported package: Internal anticollision protection, external export wooden box packaging.

2 Shipping by express, by air, by sea according to customers' requirements to find the most suitable way.

3 Responsible for the damage during the shipping process, will change the damage part for you for free.

DELIVERY TIME:15-20 days after confirming order,detail delivery date should be decided according to production season and order quantity

ONLINE

ONLINE +86 13174506016

+86 13174506016 Louis@lithmachine.com

Louis@lithmachine.com +86 18559646958

+86 18559646958

18659217588

18659217588