- Language:

English ▼

English ▼

English ▼

English ▼ItemNo :

LITH-XFT550AMOQ :

1Compliance:

CE CertifiedWarranty:

2 yearsDelivery Time:

5 days

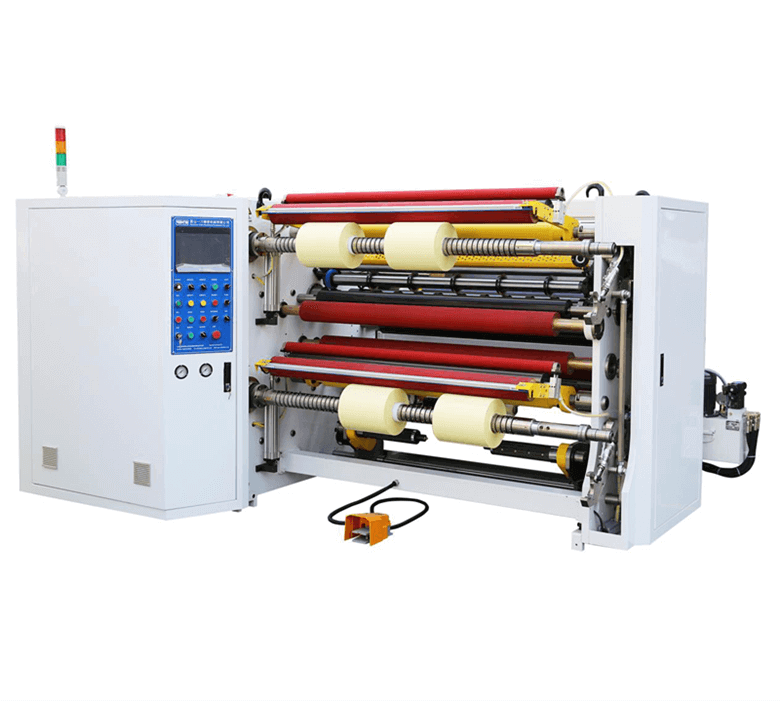

Automatic Electrode Roll-to-Roll Slitter with Dual-Shaft Rewinding Structure for Lithium Battery

The Slitting Machine is mainly intended for slitting electrode sheets of lithium-ion batteries. As a mature, stable model, it has been widely utilized in our company. The machine supports a slitting width range of 15–380 mm, is user-friendly, and meets various slitting process requirements. It adopts a dual-shaft rewinding structure: the electrode sheet is mounted on the unwind shaft, passively unwound via the drive roller, and guided automatically. After passing through the slitting blades and iron powder removal unit, the electrode sheet is slit and rewound according to process requirements. The machine is easy to operate, with simple loading and threading, stable performance, and excellent slitting results.

· Production Capacity: Max mechanical speed is 80 m/min; typical production speed is 0.5–50 m/min with stepless adjustment.

· Rewinding Alignment Accuracy: ≤ ±0.5 mm (assuming good incoming material quality).

· Pass Rate: ≥ 99% (excluding factors such as poor incoming material).

· Utilization Rate: ≥ 95% (excluding material replacement and incoming quality issues).

|

No. |

Component Name |

Description |

Quantity (sets) |

|

1 |

Main Frame Assembly |

Electrical cabinet, side plates, mounting panels |

1 |

|

2 |

Unwinding Unit |

Air-expanding shaft, tension roller, locking cylinder, web guiding unit |

1 |

|

3 |

Splicing Platform |

Pressure cylinder, pressure bar, splicing platform |

1 |

|

4 |

Unwind Tension Unit |

Tension controller, sensors, rollers |

1 |

|

5 |

Drive Unit |

Motor, drive roller, press roller, pressure adjustment system |

1 |

|

6 |

Adjustment Roller Unit |

Pre-slitting and post-slitting upper/lower adjustment rollers |

3 |

|

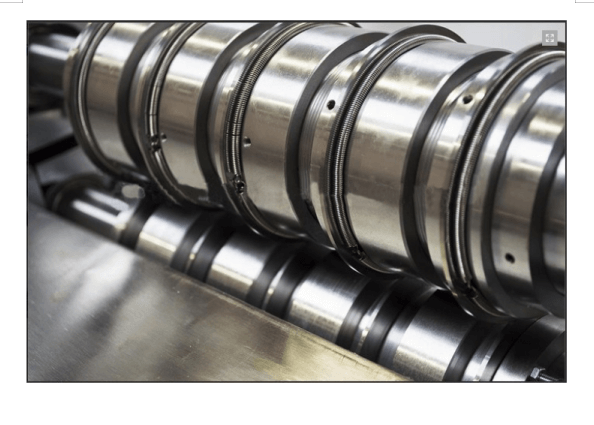

7 |

Knife Holder Assembly |

Upper and lower knife shafts, adjustment rollers, drive, dust removal |

1 |

|

8 |

Dust Removal Unit |

Blade dust removal and electrode powder brushing with 8 brush boxes |

2 |

|

9 |

Iron Removal Unit |

Magnetic bars and holders, magnetic strength 6000 Gauss |

4 |

|

10 |

Pressing Belt Unit |

Upper and lower pressing belt structures |

1 |

|

11 |

Rewind Tension Unit |

Upper/lower tension systems and sensors |

1 |

|

12 |

Tracking Roller Unit |

Upper and lower tracking rollers |

1 |

|

13 |

Rewind Unit |

Slip shafts, pressure rollers, motors |

2 |

|

14 |

Edge Trim Unit |

Guide rollers, pressure rollers, waste bins |

1 |

The equipment workflow is outlined as follows:

Web Threading Procedure:

1. Use a transfer cart to load material onto the unwind shaft.

2. Manually thread the electrode sheet through the splicing unit.

3. Guide it through the tension system.

4. Manually feed the sheet to the slitting blades for pre-slitting.

5. Pass the pre-slit sheet through the dust and iron removal system.

6. Place the core sleeve onto the slip shaft.

7. Tape the electrode sheet onto the core sleeve on the slip shaft.

8. Set the required sheet tension.

9. Switch the web guiding system to automatic mode.

10. Press the system start button.

11. The equipment automatically slits and rewinds the material into rolls.

![]()

Power Processing→Power Grinding→Vacuum Mixing→Electrode Coating→Roll Press→Sheet Cutting→Vacuum Drying→Ultrasonic Welding→Electrode Winding→Spot Welding→Grooving→Glove Box→Electrolyte Injection→Electrode Diffusion→Hydraulic Sealing→Battery Analyzer

Related Machine

|

|

|

|

|

|

|

Electrode Slitting |

Welding Power: 80-6500W optional |

Lab cylindrical cell grooving machine |

Manual Sealing or Pneumatic Sealing Machine |

8 Channel Battery Tester

|

![]()

![]()

![]()

PACKAGE:

1 Standard exported package: Internal anticollision protection, external export wooden box packaging.

2 Shipping by express, by air, by sea according to customers' requirements to find the most suitable way.

3 Responsible for the damage during the shipping process, will change the damage part for you for free.

DELIVERY TIME:15-20 days after confirming order,detail delivery date should be decided according to production season and order quantity

ONLINE

ONLINE +86 13174506016

+86 13174506016 Louis@lithmachine.com

Louis@lithmachine.com +86 18559646958

+86 18559646958

18659217588

18659217588