- Language:

English ▼

English ▼

English ▼

English ▼ItemNo :

Lith-PC-JS09MOQ :

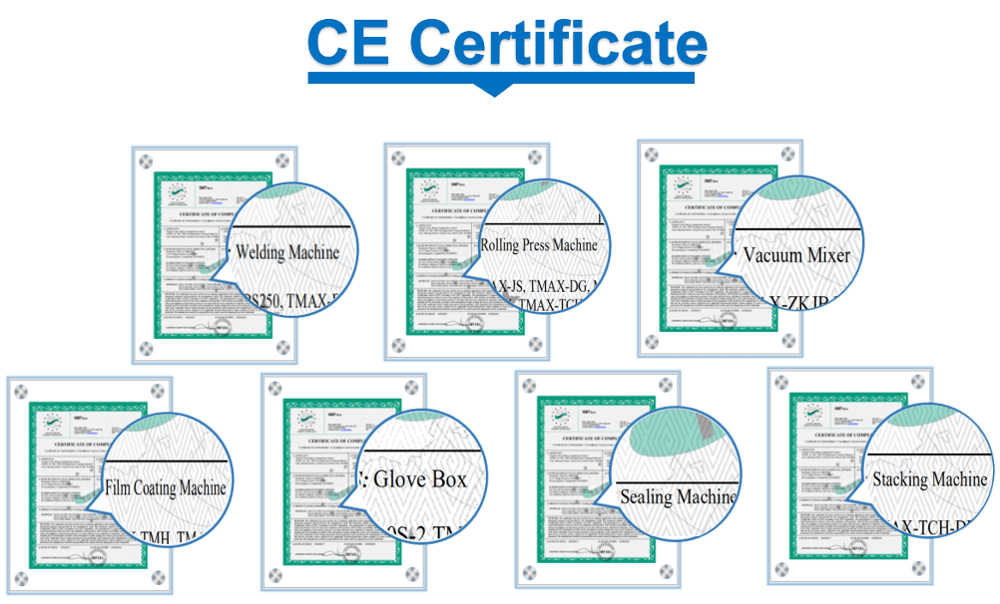

1Compliance:

CE CertifiedWarranty:

1 yearDelivery Time:

5 days

Model: Lith-PC-JS09 -Multi-target, Multi-film Deposition

|

Parameter |

Specification |

|

Chamber Design |

Single-chamber, vertical front-loading (stainless steel/vacuum-grade materials) |

|

Base Vacuum |

≤5×10−5 Pa |

|

Pump-down Time |

100 min (to ≤5×10−4 Pa after N2 venting) |

|

Leak Rate |

≤5×10−7 Pa·L/s |

|

Magnetron Targets |

3 × 3-inch (2 standard-field, 1 high-field, DC/RF compatible, Kurt J. Lesker) |

|

Power Supplies |

1 × RF (600 W, 13.56 MHz), 2 × DC (1000 W, AE Corp.) |

|

Substrate Stage |

3-position, rotating (5–30 RPM), heated (up to 450°C), bias voltage (1000 V) |

|

Target-Substrate Distance |

40–120 mm (80–120 mm with ion source) |

|

Gas Control |

2-channel MKS mass flow controllers (Ar + reactive gases) |

|

Film Thickness Uniformity |

≤5% on 2-inch area (Cu/Al: 4–5 µm, Ni/PTFE: 1–2 µm) |

|

Adhesion Test |

Passes 3× tape test (glass, Si, ceramic substrates) |

|

Additional Features |

Reverse sputtering, anode-layer ion source, safety interlocks, computer control |

· Uniform films with ≤5% thickness variation, ideal for research and prototyping.

· Multi-layer capability (e.g., Al/Ni, Al/PTFE) with automated target switching.

✔ Advanced Process Control

· Computer-controlled deposition (temperature, rotation, gas flow).

· Ion-assisted deposition enhances film density and adhesion.

✔ Flexible & Reliable Design

· Three-target system supports diverse materials (metals, dielectrics, semiconductors).

· Substrate heating (450°C) and rotation ensure high-quality coatings.

✔ Research-Optimized Safety

· Fail-safe protections (water/power interlocks, anti-misoperation).

· Controlled environment with bake-out and contamination liners.

· Academic & Industrial R&D: Thin-film studies, optoelectronics, protective coatings.

· Semiconductor & MEMS: Precise metal/dielectric layers for device fabrication.

· Advanced Materials: Hard coatings (e.g., tooling), functional films (e.g., PTFE).

· Repeatable results with automated workflows.

· Imported critical components (Kurt J. Lesker targets, AE power supplies) ensure reliability.

· Compact footprint with full-featured capabilities for labs.

![]()

![]()

![]()

PACKAGE:

1 Standard exported package: Internal anticollision protection, external export wooden box packaging.

2 Shipping by express, by air, by sea according to customers' requirements to find the most suitable way.

3 Responsible for the damage during the shipping process, will change the damage part for you for free.

DELIVERY TIME: 15-20 days after confirming order,detail delivery date should be decided according to production season and order quantity

ONLINE

ONLINE +86 13174506016

+86 13174506016 Louis@lithmachine.com

Louis@lithmachine.com +86 18559646958

+86 18559646958

18659217588

18659217588