- Language:

English ▼

English ▼

English ▼

English ▼ItemNo :

LITH-EQ-SPCWMOQ :

1Compliance:

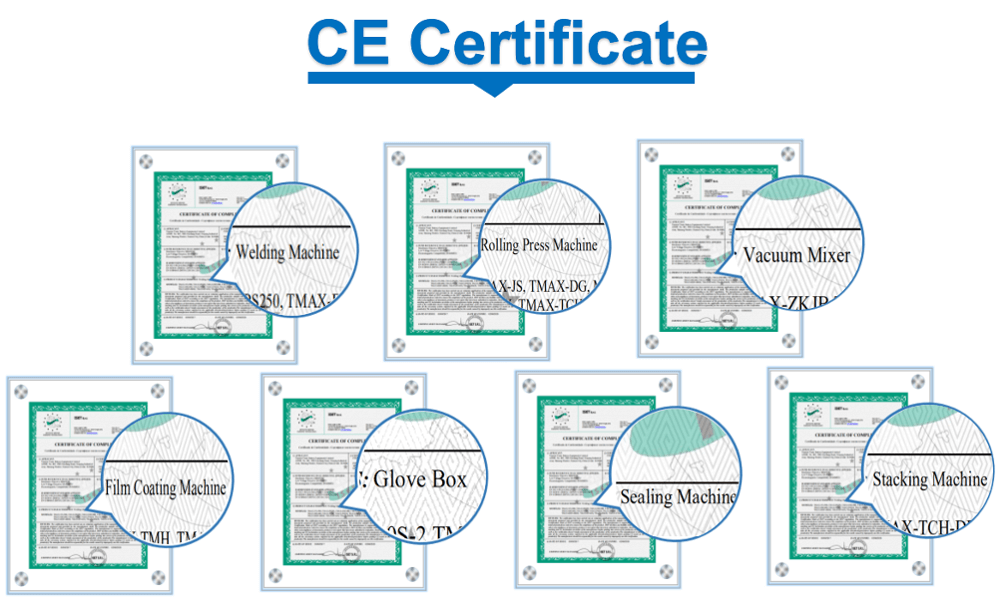

CEWarranty:

2 yearsDelivery Time:

5 daysSplitable Pouch Cells with Different Size for Battery R&D

SPECIFICATIONS:

|

Specifications |

||||

|

Design Fearture |

· Easy assembling by only four cap mounting screws · Easy to separate after test for microstructure analysis · Space saving, compact design allows you put it into the glove box |

|||

|

Material |

· Nylon or PEEK (Poly Ether Ether Ketone) selectable from product options bar · Body: Electrolyte corrosive-proof Nylon which can sustain with temperature up to 80ºC and O-ring: Sealed by electrolyte corrosive-proof PTFE O-rings · Body: PEEK (Poly Ether Ether Ketone), which is a semicry stalline thermoplastic with excellent mechanical and chemical resistance properties that are retained to high temperatures and O-ring: Sealed by electrolyte corrosive-proof FKM O-rings |

|||

|

Appearance |

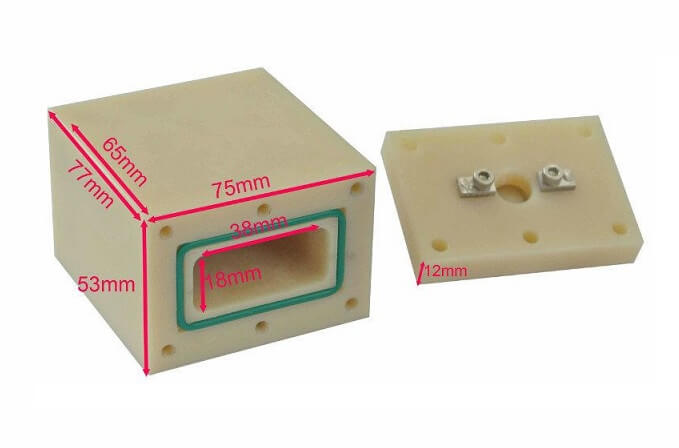

EQ-SPC-654519

|

EQ-SPC-804019

|

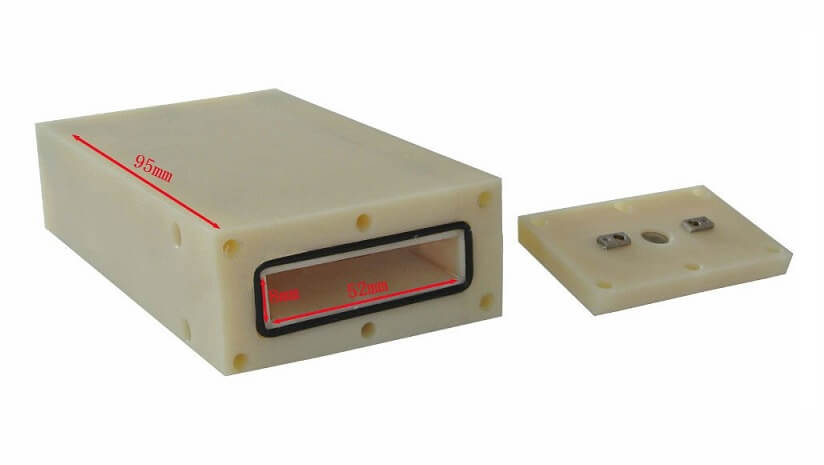

EQ-SPC-955208

|

EQ-SPC-30529525

|

|

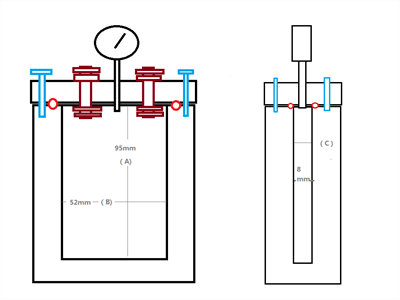

Inside chamber Dimensions |

· 65 mm H x 45mm W x19 mm Thick |

· 80 mm H x 40mmW x 19 mm Thick |

· 95 mm H x 52mm W x 8 mm Thick

|

· 305 mm H x 295.5 mm W x 25.4 mm Thick |

|

Suggested Max. electrode area |

· 60mm H x 40 mm |

· 75 mm H x 35 mm |

· 80mm H x 50mm |

· 300mm H x 395mm |

|

Outside Case Dimensions |

· 89 mm H x 75 mm W x 53 mm Thick |

· 93 mm H x 85 mm W x 55 mm Thick |

· 120mm H x 85 mm W x 40mm Thick |

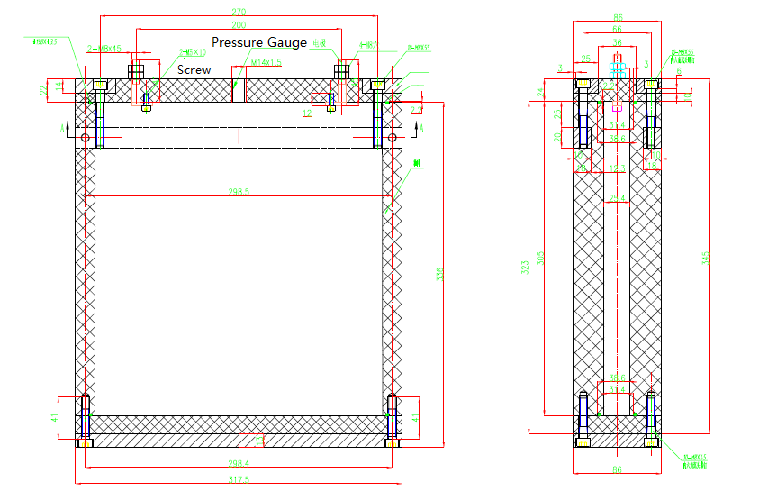

· 317.5 mm H x 323 mm W x 86 mm Thick |

|

Structure |

· One digital pressure gauge installed on top to monitor pressure. You may remove the gauge and use 1/4 female port to inject electrolyte into the pouch cell · Two stainless steel contacts to connect anode and cathode by the screw. · Max. working temperature:80°C.for Nylon, and 120oC for PEEK · Max.working Presssure:36psi (0.25MPa) for Nylon and 60psi (0.4Mpa) for PEEK |

|||

![]()

Pouch Cell Process: Tube Furnace/ Muffle Furnace→ Vacuum Mixing→ Electrode Coating→ Roll press→ Electrode Cutting→ Vacuum Drying→ Cases Forming→ Top&Side Sealing→ Electrolyte Filling→ Vacuum Sealing→ Battery Analyzer

For the pouch cell assembly, we also recommend you the following items:

![]()

![]()

![]()

1 Standard exported package: Internal anticollision protection, external export wooden box packaging.

2 Shipping by express, by air, by sea according to customers' requirements to find the most suitable way.

3 Responsible for the damage during the shipping process, will change the damaged part for you for free.

DELIVERY TIME:15-20 days after confirming the order, detail delivery date should be decided according to

production season and order quantity.

ONLINE

ONLINE +86 13174506016

+86 13174506016 Louis@lithmachine.com

Louis@lithmachine.com +86 18559646958

+86 18559646958

18659217588

18659217588