- Language:

English ▼

English ▼

English ▼

English ▼ItemNo :

LITH-300HHMOQ :

1Warranty:

2 yearsDelivery Time:

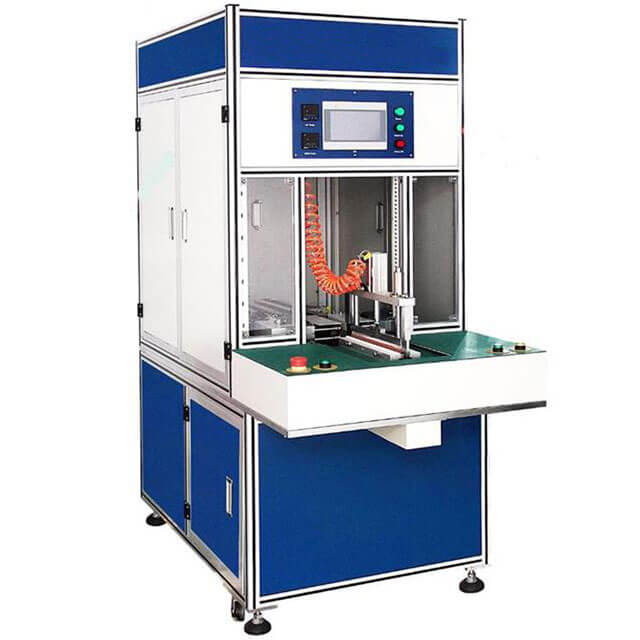

5 daysSemi-Auto Pouch Cell Production Three-In-One Machine for Edge Ironing Trimming and Folding

LITH-300HH is a three-in-one machine provides the continuous workflow for edge trimming, folding and ironing of extra large pouch cell cases without dedicated labor. This process is widely used in the final steps of pouch cell battery pilot-scale production line to ensure a smooth, neat and tidy casing edge.

|

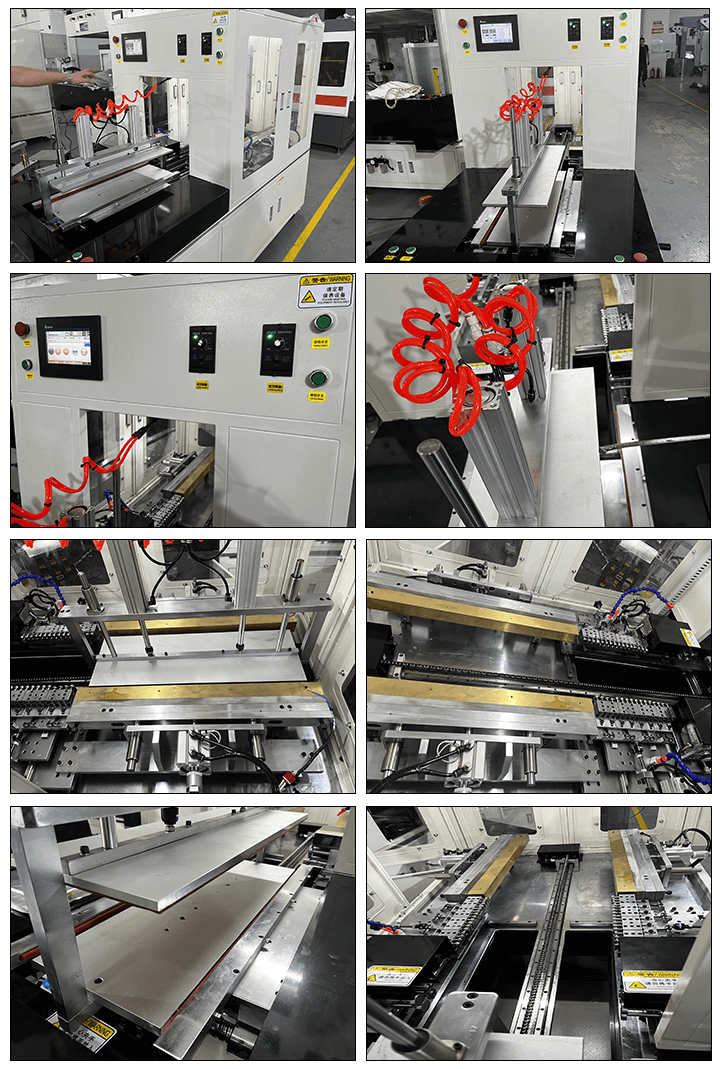

Ironing Module |

|

|

Trimming Module |

|

|

Folding Module |

|

|

Max. Power Consumption |

2.5KW |

|

Working Voltage |

208-240 VAC, single phase |

|

Compress Air Pressure |

· 0.7 - 0.8 MPa (Each stroke will consume 0.09L air ) · Note:Air Compressor is not included. |

|

Size Info (Edge Ironing, Trimming & Folding Width/Length) |

· Cell length: 10~580mm · Cell width: 10~240mm · Cell thickness: 2~12mm |

|

Temperature Info |

Ironing Temperature: 0-250℃ adjustable |

|

Dwell Time |

0-99 seconds adjustable |

|

Productivity |

160~220 pcs / hr (Expected lifespan of Trimming blade ~ 1 million times) |

|

Trimming accuracy |

+/-0.1mm |

|

Working Modes

|

· Continuous workflow for edge trimming, folding and ironing of extra large pouch cell cases (manual cases loading is needed) · Linear sliding rail for easy manipulation of trimming, folding and ironing modules.

|

|

How to use

|

When the pouch cell is fabricated, an uneven edging excess is expected. In order to make a neat and tidy cell with smooth edge just like the commercial pouch batteries, please follow the steps in below:

|

|

Product Dimensions |

2000X 850 X 1800 mm |

|

Net Weight |

360Kg |

|

Warranty |

Two Years limited warranty with lifetime support. |

![]()

Pouch Cell Process: Tube Furnace/ Muffle Furnace→ Vacuum Mixing→ Electrode Coating→ Roll press→ Electrode Cutting→ Vacuum Drying→ Cases Forming→ Top&Side Sealing→ Electrolyte Filling→ Vacuum Sealing→ Battery Analyzer

For the pouch cell assembly, we also recommend you the following items:

![]()

![]()

![]()

PACKAGE:

1 Standard exported package: Internal anticollision protection, external export wooden box packaging.

2 Shipping by express, by air, by sea according to customers' requirements to find the most suitable way.

3 Responsible for the damage during the shipping process, will change the damaged part for you for free.

DELIVERY TIME:15-20 days after confirming the order, detail delivery date should be decided according to

production season and order quantity.

ONLINE

ONLINE +86 13174506016

+86 13174506016 Louis@lithmachine.com

Louis@lithmachine.com +86 18559646958

+86 18559646958

18659217588

18659217588