- Language:

English ▼

English ▼

English ▼

English ▼ItemNo :

LITH-SCK200MOQ :

1Warranty:

2 yearsDelivery Time:

5 daysPouch Cell Case Forming Machine With Optional Die

Application

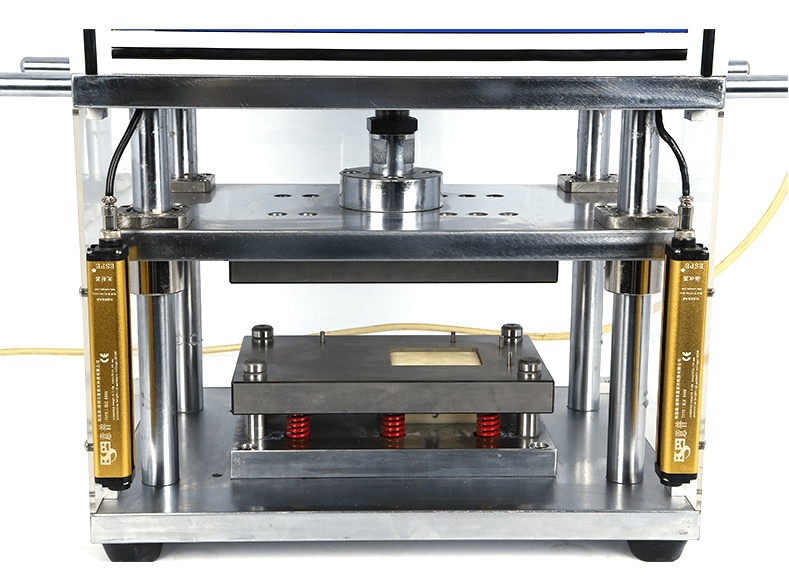

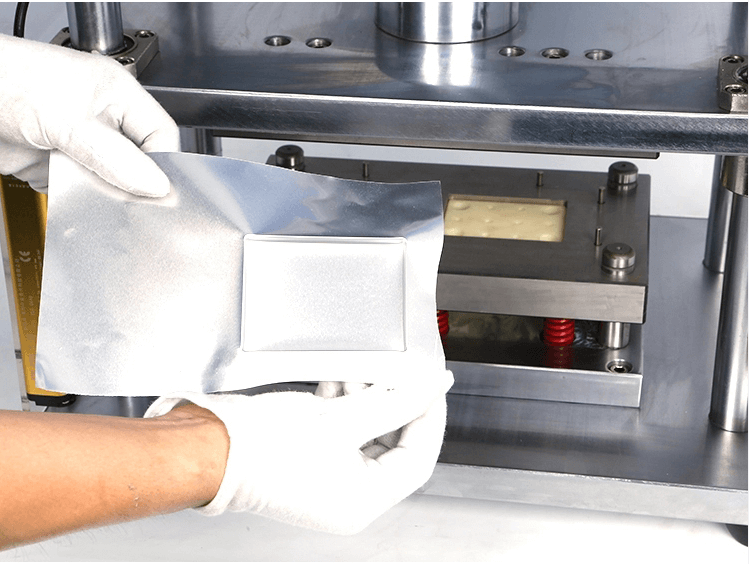

The LITH-SCK200 is a semi-automatic pouch cell forming machine specifically designed for pouch cell aluminum-laminated film case forming. It utilizes a booster cylinder to convert low air pressure into high hydraulic output, driving the mold to shape the aluminum-laminated film into a case for pouch cell lithium batteries.

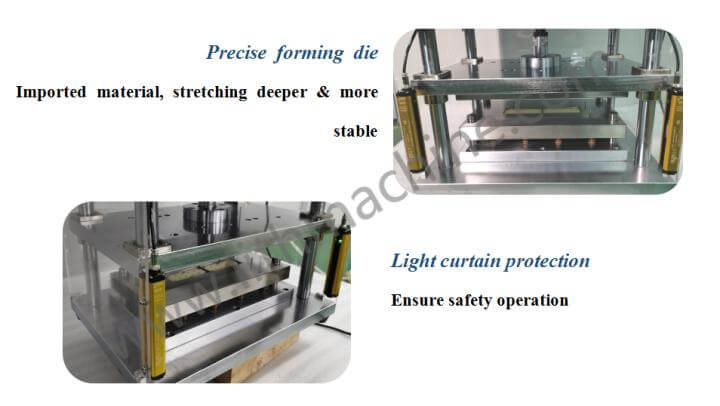

· Quick and easy adjustment of forming depth.

· Fast mold replacement, enhancing operational efficiency.

· No fish-tail or corner collapse after forming, ensuring clean product contours.

· Four-guide pillar structure for smooth and precise vertical motion.

· Safety ensured with light curtain, dual-button controls, and protective covers.

· Compared with similar machines, this model provides deeper and more stable forming results with equivalent film quality.

· Compact, safe, and user-friendly, suitable for lab or pilot production use.

|

Model |

LITH-SCK200 |

LITH-SCK300 |

|

Applicable Aluminum-laminated Film Size |

Max. L200mm × W150mm (customizable) |

Max. L300mm × W280mm (customizable) |

|

Booster Cylinder |

3T (adjustable) |

5T (adjustable) |

|

Counting Mode |

Digital counter display |

Digital counter display |

|

Power Supply |

AC220V / 50Hz |

AC220V / 50Hz |

|

Power Consumption |

100W |

100W |

|

Compressed Air Supply |

0.5–0.7MPa |

0.5–0.7MPa |

|

Machine Dimensions |

L460mm × W320mm × H925mm |

L560mm × W420mm × H925mm |

|

Machine Weight |

Approx. 180kg |

Approx. 210kg |

|

Mold/Mandrel Roughness |

Ra 0.4 |

Ra 0.4 (mirror polished) |

|

Upper/Lower Mold Flatness |

0.02mm |

0.02mm |

|

Mandrel Flatness |

0.02mm |

0.02mm |

|

Max. Forming Depth |

Max. 6mm (depends on film strength) |

Max. 6mm (depends on film strength) |

![]()

Pouch Cell Process: Tube Furnace/ Muffle Furnace→ Vacuum Mixing→ Electrode Coating→ Roll press→ Electrode Cutting→ Vacuum Drying→ Cases Forming→ Top&Side Sealing→ Electrolyte Filling→ Vacuum Sealing→ Battery Analyzer

For the pouch cell assembly, we also recommend you the following items:

![]()

![]()

![]()

1 Standard exported package: Internal anticollision protection, external export wooden box packaging.

2 Shipping by express, by air, by sea according to customers' requirements to find the most suitable way.

3 Responsible for the damage during the shipping process, will change the damaged part for you for free.

DELIVERY TIME:15-20 days after confirming the order, detail delivery date should be decided according to

production season and order quantity.

ONLINE

ONLINE +86 13174506016

+86 13174506016 Louis@lithmachine.com

Louis@lithmachine.com +86 18559646958

+86 18559646958

18659217588

18659217588