- Language:

English ▼

English ▼

English ▼

English ▼ItemNo :

LITH-YS-CMOQ :

1Warranty:

2 yearsDelivery Time:

5 days

LITH-YS-C the Semi-automatic winding machine for accurate assembly. The separator film is sandwiched between the cathode and anode materials and then rolled up into a Prismatic core at constant tension force. This is an ideal tool provides the reliability and precision to produce high-quality winding of electrode cores.

Outstanding Features:

· PLC Touch Screen Control

· Unreeling rotors for separator film feeding

· Passive tension control; tension is adjustable

· Automatic finish cut after the completion of jelly roll winding

SPECIFICATIONS:

|

Model |

YS-BLY80 |

YS-BFX130 |

YS-BFX180 |

|

Cathode / Anode Winding |

· Cathode: Aluminum foil coated with an active material such as LiFePo4, LiCoO2, and so on... · Anode: Copper foil coated with graphite · Thickness Range: 0.1-0.2mm · Suggested Overall Length: <250~2500mm · Maximum Width: 18-80mm |

· Cathode: Aluminum foil coated with an active material such as LiFePo4, LiCoO2, and so on... · Anode: Copper foil coated with graphite · Thickness Range: 100~300um · Suggested Overall Length: <1500mm · Maximum Width: 128mm |

· Cathode: Aluminum foil coated with an active material such as LiFePo4, LiCoO2, and so on... · Anode: Copper foil coated with graphite · Thickness Range: 100~300um · Suggested Overall Length: <1500mm · Maximum Width: 178mm |

|

Separator Winding |

· PP or PE · Thickness Range: < 0.016-0.045mm · Separator roll diameter:300mm · Width: 20-80mm |

· PP or PE · Thickness Range: <100um · Max. adaptable size: · Thickness: < 10 mm · Width: 60 - 130 mm |

· PP or PE · Thickness Range: <100um · Max. adaptable size: · Thickness: < 10 mm · Width: 60 - 180 mm |

|

Winding Blade Width |

30 - 100mm |

30 - 100mm |

30 - 100mm |

|

Working Voltage |

Single-phase 110-240VAC, 50/60Hz |

||

|

Max. Power Consumption |

1.5KW |

||

|

Winding Accuracy |

Edge Evenness: <0.5mm |

||

|

Tension Control |

<150g adjustable |

||

|

Winding Speed |

0 - 400 RPM adjustable |

||

|

Feeder Bed |

1500mm Long |

||

|

Compressed Air Requirement |

0.7MPa (Please note that an air compressor is needed for the operation of this machine. Air Compressor is NOT included.) |

||

|

Warranty |

Two Years Limited Warranty With Lifetime Support |

||

|

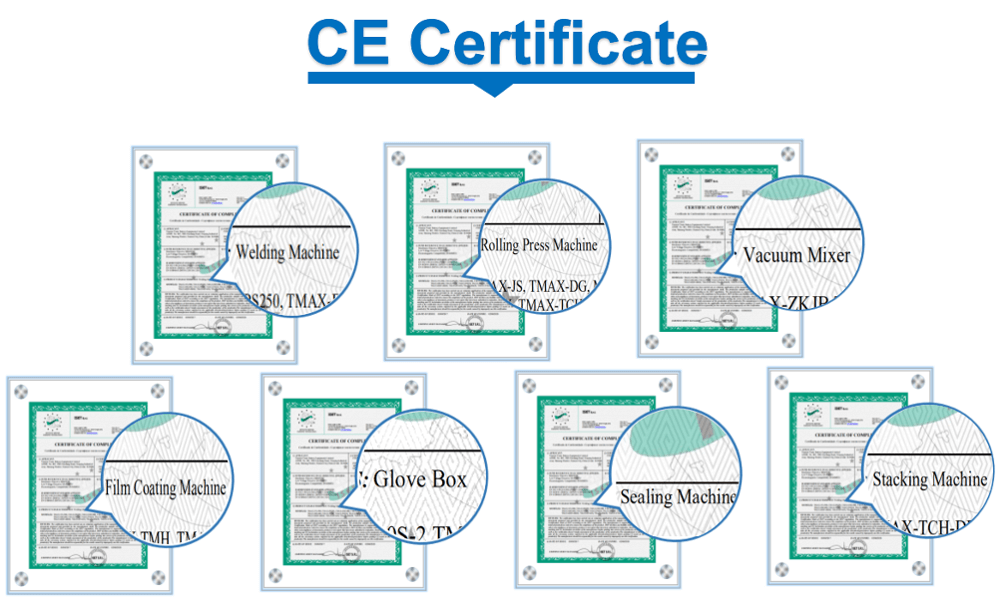

Compliance |

CE certified |

||

![]()

![]()

![]()

![]()

1 Standard exported package: Internal anticollision protection, external export wooden box packaging.

2 Shipping by express, by air, by sea according to customers' requirements to find the most suitable way.

3 Responsible for the damage during the shipping process, will change the damaged part for you for free.

DELIVERY TIME:15-20 days after confirming the order, detail delivery date should be decided according to

production season and order quantity.

ONLINE

ONLINE +86 13174506016

+86 13174506016 Louis@lithmachine.com

Louis@lithmachine.com +86 18559646958

+86 18559646958

18659217588

18659217588