- Language:

English ▼

English ▼

English ▼

English ▼ItemNo :

LITH-CB-PilotMOQ :

1Place of Origin:

ChinaWarranty:

2 yearsDelivery Time:

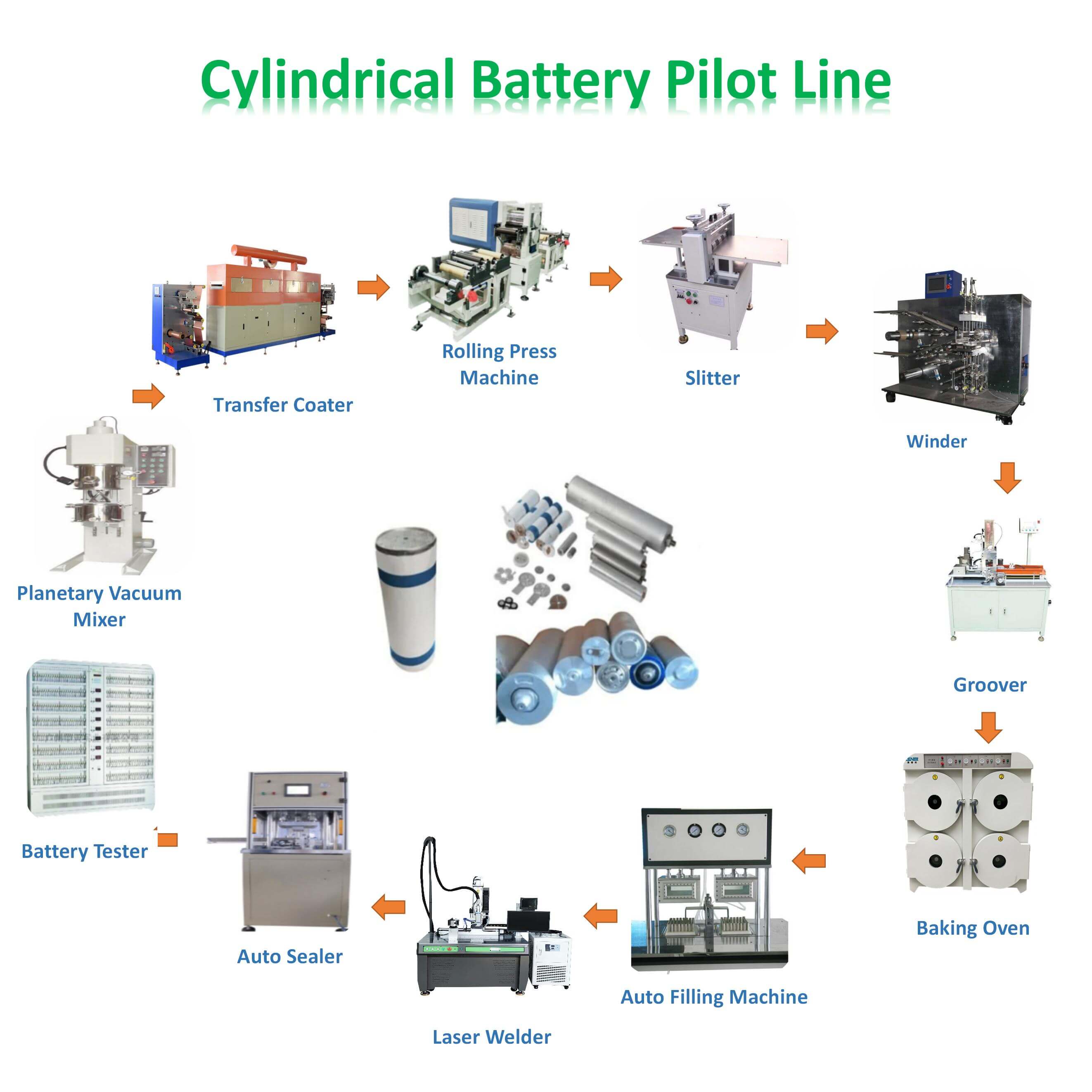

5 daysLi-ion 186560 21700 26650 32650 32700 AA AAA Cylindrical Battery Pilot Line Fabrication & Equipment

1. Introduction:

LITH is a leading manufacturer of affordable, compact, and durable battery research equipment. Our expert engineering team will assist and provide customers with the necessary guidance in selecting the most cost effective technology solution for all research needs.

2.LITH Cylinder Cell Pilot Line Process and Equipment:

|

No. |

Process |

Equipment Name |

|

1 |

Raw material baking |

Vacuum Drying Oven with Tri-Level Shelf Heating Modules |

|

2 |

Vacuum Mixing |

Large Planetary Vacuum Mixer with Vacuum Pump and Water Chiller |

|

3 |

Slurry viscosity Test |

Digital Touch Screen Viscometer |

|

4 |

Vacuum Mixing |

Turnover Bucket |

|

5 |

Magnetic De-Ironing Filtration |

Magnetic De-ironing Filtration System for Battery Electrode Slurry |

|

6 |

Electrode Coating |

3 Rollers Battery Electrode Intermittent Coating Machine |

|

7 |

Waste Gas Treatment |

Solvent Processing System Waste Gas Treatment Equipment |

|

8 |

Roll press |

Roll to Roll Pressure Controlled |

|

9 |

Electrode Sheet Cross Cutting |

Lithium Battery Electrode Sheet Cutter Machine for Battery Big Electrode |

|

10 |

Electrode Sheet Slitting |

Battery Electrode Roll Slitting Machine |

|

11 |

Sticking glue of lithium ion battery electrode |

Lithium ion Battery Electrode Piece Sticking Machine |

|

12 |

Tab Welding |

Al Tab Ni Tag Ultrasonic Welding Machine |

|

13 |

Electrode Winding |

Automatic Precision Winding Machine |

|

14 |

Put the cell into the battery shell, and weld the negative electrode lug and the negative electrode shell with a spot welder |

Precision High Frequency Inverter DC double Pulse Spot Welding Machine |

|

15 |

Short circuit tesing |

Short Circuit Tester |

|

16 |

The battery shell is formed by rolling groove, which is convenient for sealing. |

Floor-stand Automatic Grooving Machine for Batch Processing of Cylindrical battery Castings |

|

17 |

Cylindrical Cell Cap Laser Welding |

Laser Welding Machine |

|

18 |

Filling the electrolyte into the battery |

Automatic Precision Electrolyte Injection Station for Cylindrical Cell Batteries |

|

19 |

Sealing the cylindrical cell cases |

Automatic Cylindrical Cell Crimping Machine |

|

20 |

Cell Formation and capacity testing |

512 Channel Lithium Ion Battery Tester Equipment |

|

21 |

Print numbers to cylindrical cells |

Continuous Small Character Ink Jet Printer |

|

22 |

Remove the moisture from the battery production process to ensure the quality of the battery |

Dehumidification and Drying System |

|

23 |

Vacuum pumping |

Monoblock Rotary-vane Vacuum Pump |

|

24 |

Provide compressed gas for each battery production machine |

Helical Compressor |

3. Cylindrical Battery Pilot Line:

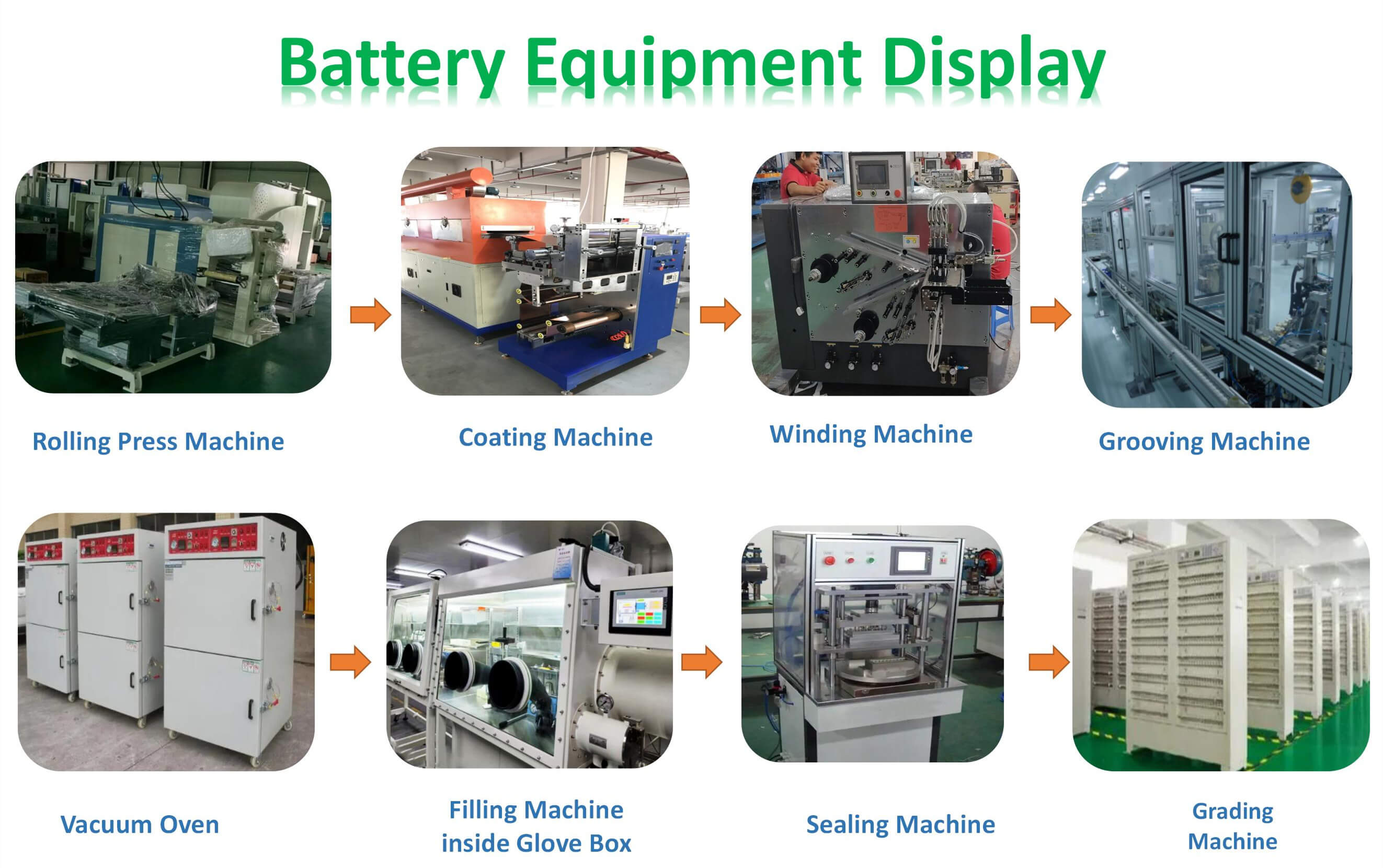

4. Battery Equipment Display:

![]()

![]()

![]()

PACKAGE:

1 Standard exported package: Internal anticollision protection, external export wooden box packaging.

2 Shipping by express, by air, by sea according to customers' requirements to find the most suitable way.

3 Responsible for the damage during the shipping process, will change the damage part for you for free.

DELIVERY TIME:15-20 days after confirming order,detail delivery date should be decided according to production season and order quantity

ONLINE

ONLINE +86 13174506016

+86 13174506016 Louis@lithmachine.com

Louis@lithmachine.com +86 18559646958

+86 18559646958

18659217588

18659217588