- Language:

English ▼

English ▼

English ▼

English ▼ItemNo :

LITH-TB300MOQ :

1Warranty:

2 yearsDelivery Time:

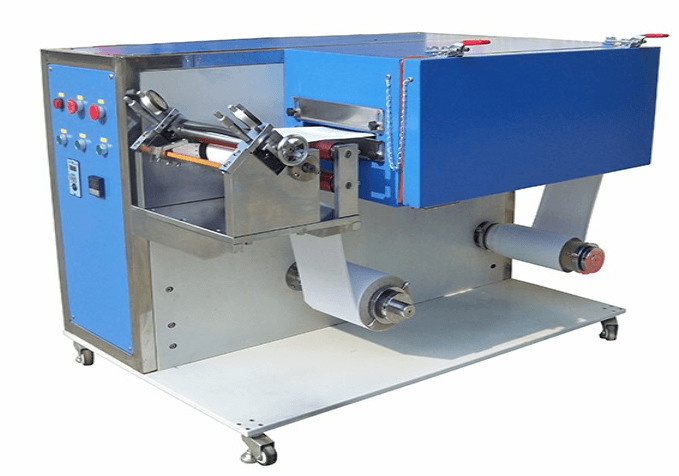

5 daysLaboratory coating machine is a new laboratory instrument developed in recent years. It is a successful innovation combining electrical control and mechanical organic. In the field of coating production, it can save a lot of raw materials and improve production technology. The key is to greatly improve the reproducibility of coating on the basis of experiments. It is specially designed and manufactured for the research and development and material inspection of battery materials in universities, research institutes and enterprise laboratories.

The equipment is mainly suitable for the coating process of positive and negative electrodes of lithium iron phosphate, lithium cobalt oxide and lithium manganate.

Specifications:

|

The thickness of the running substrate |

aluminum foil 11 ~ 30um; copper foil 8 ~ 30um; |

|

The maximum width of coating |

280mm |

|

The maximum speed of mechanical transport |

5m / min; Speed accuracy ± 0.1m / min |

|

Coating speed |

>5m/min |

|

Suitable for slurry viscosity |

1500~15000 Cps Suitable for coating single-sided dry thickness 30~200μm |

|

Coating accuracy |

dry and thick double-sided precision error : <±0.004mm; dry thickness single-sided precision <±0.002mm |

|

Coating alignment error on the front and back sides |

<±0.5mm Average length error ≤±0.5mm |

|

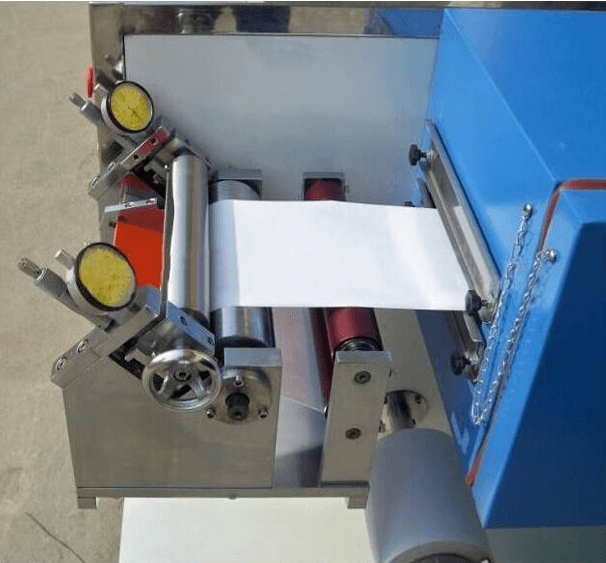

Coating roller accuracy |

<±0.001mm, scraper is comma knife |

|

Core diameter |

3 inch shaft |

|

Oven temperature control accuracy |

< ± 3 ° C, drying oven temperature independent PID adjustable |

|

Power |

5.5 (KW) |

|

Coating method |

continuous coating |

|

Can move |

with 4 universal wheels |

|

The weight |

450KG |

![]()

Pouch Cell Process: Tube Furnace/ Muffle Furnace→ Vacuum Mixing→ Electrode Coating→ Roll press→ Electrode Cutting→ Vacuum Drying→ Cases Forming→ Top&Side Sealing→ Electrolyte Filling→ Vacuum Sealing→ Battery Analyzer

For the pouch cell assembly, we also recommend you the following items:

![]()

![]()

![]()

1 Standard exported package: Internal anticollision protection, external export wooden box packaging.

2 Shipping by express, by air, by sea according to customers' requirements to find the most suitable way.

3 Responsible for the damage during the shipping process, will change the damaged part for you for free.

DELIVERY TIME:15-20 days after confirming the order, detail delivery date should be decided according to production season and order quantity.

ONLINE

ONLINE +86 13174506016

+86 13174506016 Louis@lithmachine.com

Louis@lithmachine.com +86 18559646958

+86 18559646958

18659217588

18659217588