ItemNo :

Lith-PD-ZD01MOQ :

1Compliance:

CE CertifiedWarranty:

1 yearDelivery Time:

5 days

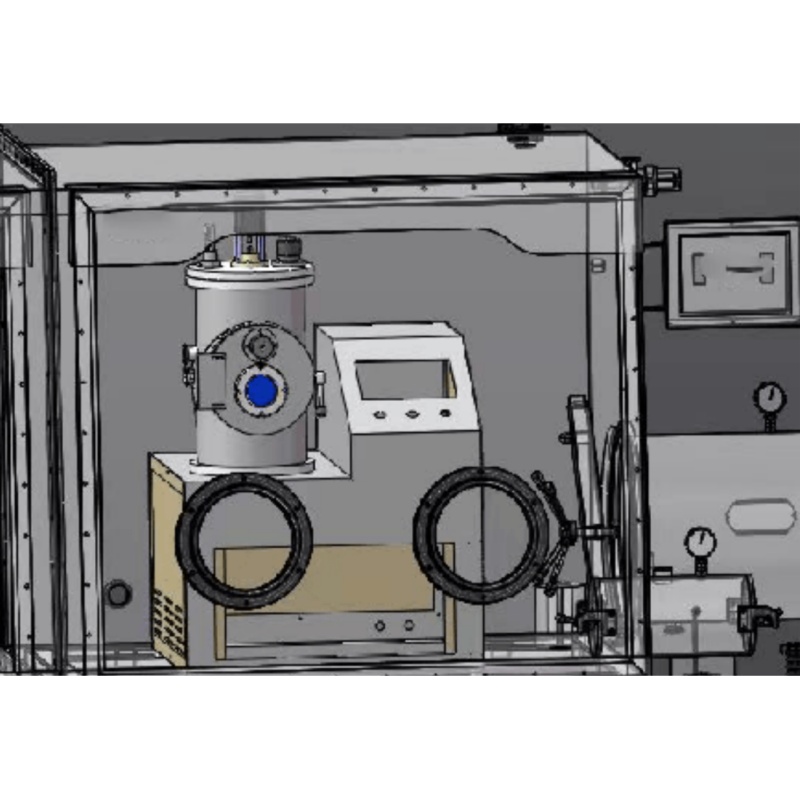

Small PVD Thin Film Deposition Coating Machine System For Metals And Organics

Lith-PD-ZD01-High-Vacuum Evaporation Coating System

This system is a compact, multi-source high-vacuum evaporation coating platform designed for laboratory use, capable of depositing thin films of metals, organics, and other functional materials. It is ideal for:

· Research labs (metal electrode fabrication, SEM sample preparation).

· Advanced materials development (organic thin films).

· Process optimization (high-precision coatings for novel material synthesis).

|

Feature |

This System |

Typical Competing Systems |

|

Vacuum Speed |

15–20 min to high vacuum (≤5×10⁻⁵ Pa) |

Often 30+ min for similar vacuum levels. |

|

Film Uniformity |

±3%–5% thickness deviation |

Typically ±5%–10% in entry-level models. |

|

Chamber Material |

304 stainless steel (high corrosion resistance) |

Some use aluminum or lower-grade steel. |

|

Modularity |

Supports 1–3 evaporation sources (expandable) |

Fixed configurations common in low-end systems. |

|

Footprint |

Compact (500×360×420mm for desktop model) |

Larger benchtop units often >600×500mm. |

|

Parameter |

Specification |

|

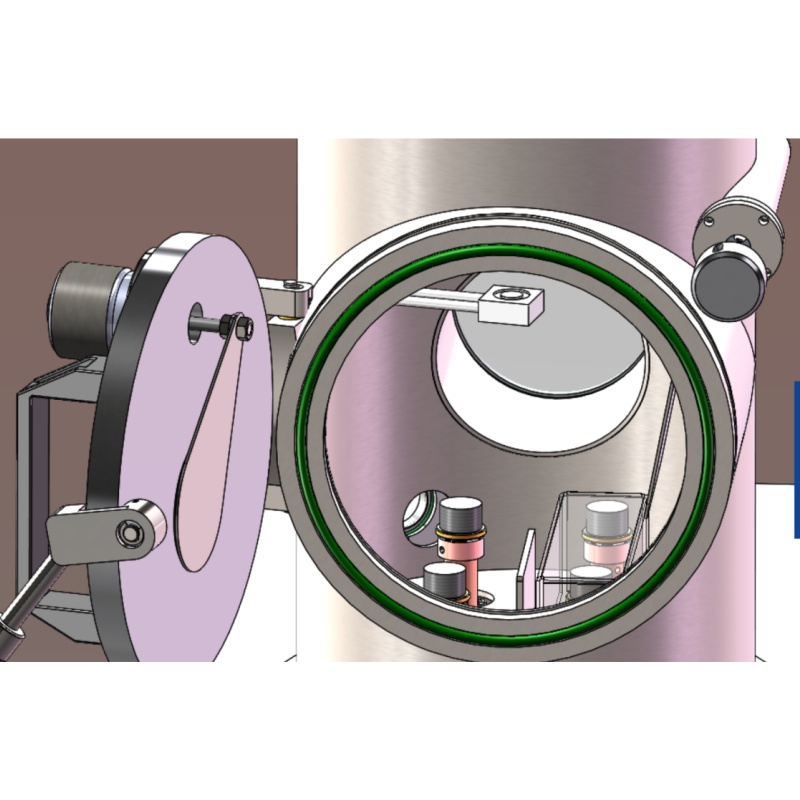

Vacuum Chamber |

304 stainless steel, cylindrical (Φ260×H350 mm) |

|

Internal Coating Area |

~Φ260×H310 mm |

|

Ultimate Vacuum |

≤5×10⁻⁵ Pa |

|

Pumping Speed |

≤8×10⁻⁴ Pa in 30 min, holds ≤5 Pa for 12 hours |

|

Substrate Stage |

- Max size: 80×80 mm (standard) / 120 mm diameter (rotary) - Rotation: 0–20 RPM (magnetic fluid sealed) |

|

Film Uniformity |

<5% (120 mm diameter area) |

|

Evaporation Sources |

2–3 sources (metal/organic compatible, co-evaporation or switching) |

|

Power Supply |

2 kW, constant current/power modes |

|

Electrical |

AC 220 V / 50 Hz, 3.5 kW |

|

Dimensions (L×W×H) |

- Main unit: 600×500×900 mm - Desktop model: 500×360×420 mm |

1. Speed & Efficiency

o Achieves high vacuum 50% faster than comparable models, reducing idle time.

2. Precision Engineering

o Stainless steel chamber + optimized gas paths ensure minimal contamination and long-term stability.

3. Flexible Configurations

o Modular design allows easy upgrades (e.g., adding a third evaporation source).

4. Space-Saving

o 30% smaller footprint than conventional systems, critical for crowded labs.

✔ Universities studying thin-film physics.

✔ R&D centers developing flexible electronics or OLEDs.

✔ Industrial labs requiring high-repeatability coatings.

Order Note: Minimum 1 unit. Custom configurations available.

![]()

![]()

![]()

PACKAGE:

1 Standard exported package: Internal anticollision protection, external export wooden box packaging.

2 Shipping by express, by air, by sea according to customers' requirements to find the most suitable way.

3 Responsible for the damage during the shipping process, will change the damage part for you for free.

DELIVERY TIME: 15-20 days after confirming order,detail delivery date should be decided according to production season and order quantity

ONLINE

ONLINE +86 13174506016

+86 13174506016 Louis@lithmachine.com

Louis@lithmachine.com +86 18659217588

+86 18659217588

18659217588

18659217588