- Language:

English ▼

English ▼

English ▼

English ▼ItemNo :

Lith-HZ-ZD01MOQ :

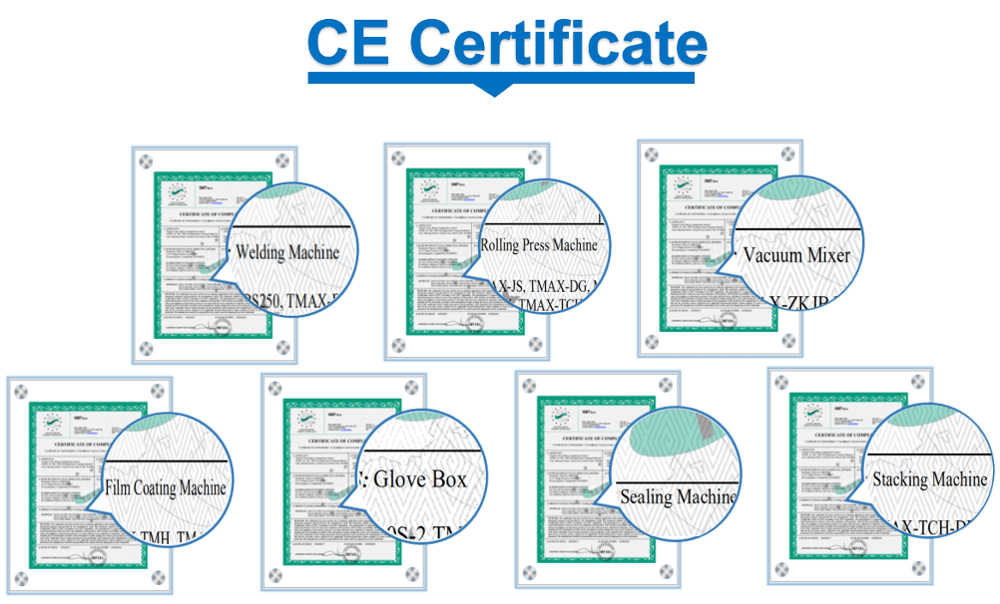

1Compliance:

CE CertifiedWarranty:

1 yearDelivery Time:

5 days

Lith-HZ-ZD01-Low-Temperature Pulsed Thermal Evaporator

The Lith-HZ-ZD01 Pulsed Carbon Coater is an advanced, fully automated instrument designed for high-quality carbon coating of samples in material science and biological research. Featuring a compact design, intelligent ARM-based control, and pulse evaporation technology, it ensures efficient, precise, and low-thermal-damage coating—ideal for high-resolution SEM analysis.

1. Ultra-Compact Design

·Dimensions: 530×300×320 mm, optimized for space-constrained labs.

2. High-Efficiency Pulse Evaporation

·W-type planar carbon source with pre-degassing function minimizes thermal impact on sensitive samples (e.g., polymers, membranes, fibers).

·Nanoscale coating (<5 nm) ensures dense, uniform films for high-resolution SEM imaging.

3. Fully Automated Operation

·5-inch touchscreen with intuitive interface (supports bilingual display).

·One-click start and ARM-based precision control (adjustable in 1 mA/1 Pa/1 s increments).

4. Multi-Sample Capacity

·Holds 12 standard stub samples simultaneously, reducing manual intervention.

5. Reliable Vacuum System

·Achieves <1 Pa ultimate vacuum via rotary vane pump; real-time monitoring with a Pirani gauge.

6. Versatile Carbon Sources

·Compatible with 0.8/1.2/2.4 mm carbon ropes or rods, detectable for continuity.

7. Safety & Stability

·Dual current/vacuum protection and sensor-monitored operation ensure long-term reliability.

|

Parameter |

Detail |

|

Power Supply |

100–250 VAC, 50/60 Hz |

|

Evaporation Type |

Pulsed W-type planar source |

|

Evaporation Power |

0–10 V DC, 80 A max |

|

Evaporation Time |

100 ms–1 s (adjustable) |

|

Working Vacuum |

2–8 Pa (display resolution: 0.1 Pa) |

|

Sample Stage |

Ø65 mm (height-adjustable) |

|

Vacuum Chamber |

Ø120×100 mm |

|

Data Monitoring |

Real-time display of current, voltage, and vacuum status |

This excels in preparing temperature-sensitive samples (e.g., organic polymers, biological tissues, electrodes) and delivers nanoscale coatings critical for:

· SEM/EDS analysis

· Conductivity enhancement

· Nanomaterial research

1. Quick Setup: Connect power/gas (optional); system self-checks upon startup.

2. Sample Loading: Adjust sample-to-source distance (~20 mm optimal).

3. Automated Process: Set parameters (vacuum/time/voltage) → Start → Automatic venting post-coating.

4. Maintenance: Tool-free carbon rope replacement; vacuum pump oil refill included.

![]()

![]()

![]()

PACKAGE:

1 Standard exported package: Internal anticollision protection, external export wooden box packaging.

2 Shipping by express, by air, by sea according to customers' requirements to find the most suitable way.

3 Responsible for the damage during the shipping process, will change the damage part for you for free.

DELIVERY TIME: 15-20 days after confirming order,detail delivery date should be decided according to production season and order quantity

ONLINE

ONLINE +86 13174506016

+86 13174506016 Louis@lithmachine.com

Louis@lithmachine.com +86 18559646958

+86 18559646958

18659217588

18659217588