- Language:

English ▼

English ▼

English ▼

English ▼ItemNo :

Lith-BY-ZD06MOQ :

1Compliance:

CE CertifiedWarranty:

1 yearDelivery Time:

5 days

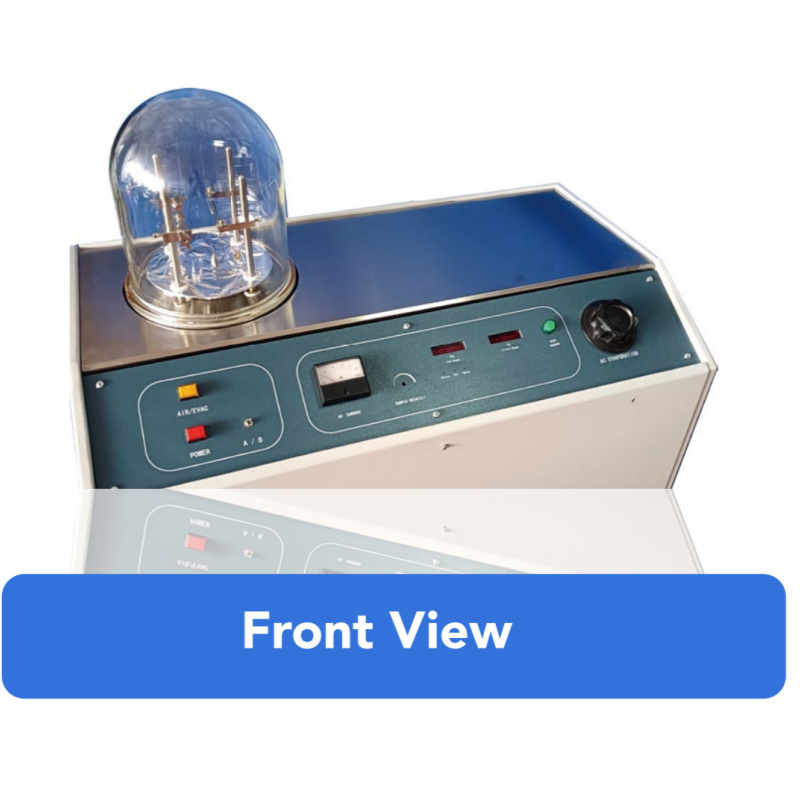

Model: Lith-BY-ZD06-High Vacuum Thermal Evaporation

|

Parameter |

Specification |

|

Evaporation Current |

Max 100 A |

|

Evaporation Voltage |

Max 10 V |

|

Heating Power |

1,000 W |

|

Chamber Size |

Ø230 mm × 280 mm (H) |

|

Working Vacuum |

2×10−3 Pa |

|

Ultimate Vacuum |

2×10−4 Pa |

|

Target Materials |

Carbon, gold & other low-melting metals |

|

Pumping System |

Mechanical pump (primary) + Turbo molecular pump (secondary) |

✔ High Vacuum & Fast Deposition

· Advanced compound molecular pump ensures rapid gas evacuation for clean, efficient coating.

· Minimized oil backflow for contamination-free operation.

✔ Reliable & Efficient

· Resistive heating technology for stable evaporation of low-melting metals.

· Simple process with high deposition rates, ideal for lab-scale production.

✔ User-Friendly Design

· Compact chamber accommodates diverse sample sizes (up to Ø230 mm).

· Low maintenance costs for routine use in R&D and academia.

· Thermal Evaporation: Gentle heating avoids high-energy plasma, ideal for sensitive samples (e.g., polymers, biomaterials).

· Sputtering Risk: Energetic ions in sputtering may alter delicate surfaces.

· Higher Deposition Rate: Rapid vaporization of metals (e.g., Au, C) reduces coating time.

· Sputtering Limitation: Slower for low-melting-point materials due to target cooling needs.

· Uniform Conductive Layers: Smooth metal films (e.g., 5–10 nm Au) prevent SEM charging effectively.

· Sputtering Consideration: Sputtered films may exhibit grainier surfaces, affecting conductivity.

· No Gas/Plasma System: Simpler operation and maintenance vs. sputtering’s gas flow/power controls.

· Cost-Effective: Lower power consumption and consumable costs (e.g., replaceable tungsten boats).

· SEM Sample Preparation: Conductive coatings for non-conductive or beam-sensitive materials.

· Thin-Film Research: Rapid prototyping of pure metal films (Au, Ag, Al).

· Industrial R&D: Process optimization for specialty coatings.

Ideal For

· Microscopy Labs – Prevents charging in non-conductive samples.

· Material Scientists – Electrode fabrication & conductivity studies.

· Universities – Teaching tool for vacuum deposition principles.

![]()

![]()

![]()

PACKAGE:

1 Standard exported package: Internal anticollision protection, external export wooden box packaging.

2 Shipping by express, by air, by sea according to customers' requirements to find the most suitable way.

3 Responsible for the damage during the shipping process, will change the damage part for you for free.

DELIVERY TIME: 15-20 days after confirming order,detail delivery date should be decided according to production season and order quantity

ONLINE

ONLINE +86 13174506016

+86 13174506016 Louis@lithmachine.com

Louis@lithmachine.com +86 18559646958

+86 18559646958

18659217588

18659217588