ItemNo :

LITH-6DCF-100AMOQ :

1Compliance:

Warranty:

2 yearsDelivery Time:

5 daysRotary Six-Station Hot Sealing Machine for Lithium-Ion Pouch Cells

1. Equipment Description

This equipment is mainly used for automatic top sealing (left and right), side heating sealing, edge trimming, flaring, and testing of pouch cell lithium-ion batteries. It is also compatible with certain prismatic cells. The machine operates with a rotary dual-station design.

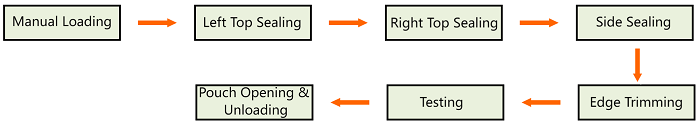

The workflow includes: loading → left top sealing → right top sealing → side sealing → edge trimming → testing → flaring → unloading.

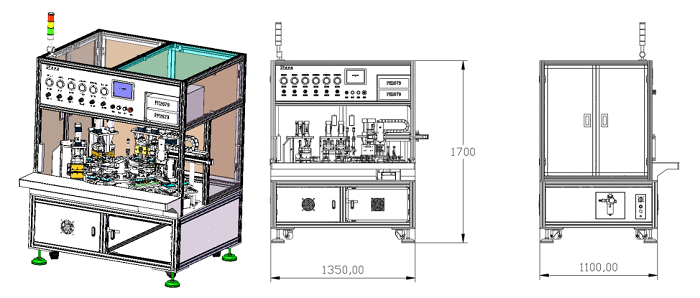

2. Equipment Schematic Diagram

(For reference only; subject to actual product)

3. Equipment Process Flow

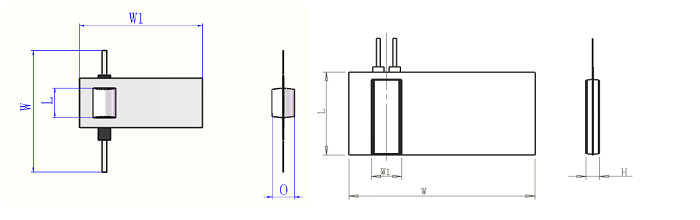

4. Applicable Battery Specifications

L=30—65mm

W1=55-90mm

W=50—90mm

O=5—22mm

Compatible Products:

By changing the fixture, the equipment can adapt to small prismatic cells.

5. Main Technical Parameters

|

Item |

Specification |

|

5.1 Equipment Efficiency |

10–14 ppm (depending on sealing parameters and operator skill) |

|

5.2 Applicable Specifications |

Cell diameter: ∮05–∮22 mm; Cell length: 30–65 mm (main body) |

|

5.3 Heating Rod Power |

500 W per rod |

|

5.4 Temperature Control Accuracy |

±3°C |

|

5.5 Sealing Head Material |

Brass |

|

5.6 Sealing Head Length |

100 mm |

|

5.7 Sealing Pressure |

0–0.6 MPa adjustable; pressure control accuracy: ±0.02 MPa |

|

5.8 Sealing Head Parallelism |

±0.015 mm |

|

5.9 Cylinder Diameter |

Upper sealing head: Ø40 mm; Lower sealing head: Ø50 mm |

|

5.10 Pass Rate |

≥98% |

6. Functional Description

l 6.1 Both top and bottom sealing use soft sealing process.

l 6.2 Locating holes are present on the cell fixture, aligned with positioning pins on the rotary table to ensure sealing precision.

l 6.3 Sealing time for top, bottom, and side sealing can be set via the touchscreen.

l 6.4 All sealing operations use pneumatic cylinders; sealing pressure is adjusted via pressure regulating valves on the control panel.

l 6.5 Temperature is controlled by temperature control modules or controllers.

l 6.6 The positioning fixture operates with a one-out-one fixture — one cell is placed per cycle.

l 6.7 The edge trimming station uses SKD11 cutting blades with a single sharpening life exceeding 300,000 cycles; can be resharpened over 10 times.

l 6.8 The testing station uses pneumatic cylinders with probes for inspection.

l 6.9 The flaring station uses a vacuum suction cup in coordination with flaring tools.

7. System Protection Functions

l 7.1 Equipped with an HMI system mounted on the frame for easy operation and debugging.

l 7.2 Equipped with protective covers for safety.

l 7.3 Includes a leakage protection switch and proper grounding to ensure operator safety.

8. Main Components

|

Component Type |

Brand |

|

Pneumatic Components |

Airtac / Xingchen |

|

Motor |

Domestic / Hechuan |

|

Linear Guide / Ball Screw |

HIWIN / Domestic |

|

PLC |

Omron / Xinje |

|

Touchscreen |

Xinje / Weinview |

9. Installation Requirements

l Power Supply: AC220V, 50Hz, Power: 2.5 kW

l Compressed Air: ≥0.6 MPa, Relative Humidity <30% RH

l Vacuum Source: ≤-95 KPa

l Equipment Weight: Approx. 800 kg

Pouch Cell Process: Tube Furnace/ Muffle Furnace→ Vacuum Mixing→ Electrode Coating→ Roll press→ Electrode Cutting→ Vacuum Drying→ Cases Forming→ Top&Side Sealing→ Electrolyte Filling→ Vacuum Sealing→ Battery Analyzer

For the pouch cell assembly, we also recommend you the following items:

![]()

![]()

![]()

PACKAGE:

1 Standard exported package: Internal anticollision protection, external export wooden box packaging.

2 Shipping by express, by air, by sea according to customers' requirements to find the most suitable way.

3 Responsible for the damage during the shipping process, will change the damaged part for you for free.

DELIVERY TIME:15-20 days after confirming the order, detail delivery date should be decided according to

production season and order quantity.

ONLINE

ONLINE +86 13174506016

+86 13174506016 Louis@lithmachine.com

Louis@lithmachine.com +86 18659217588

+86 18659217588 18659217588

18659217588