ItemNo :

LITH- HC-520AMOQ :

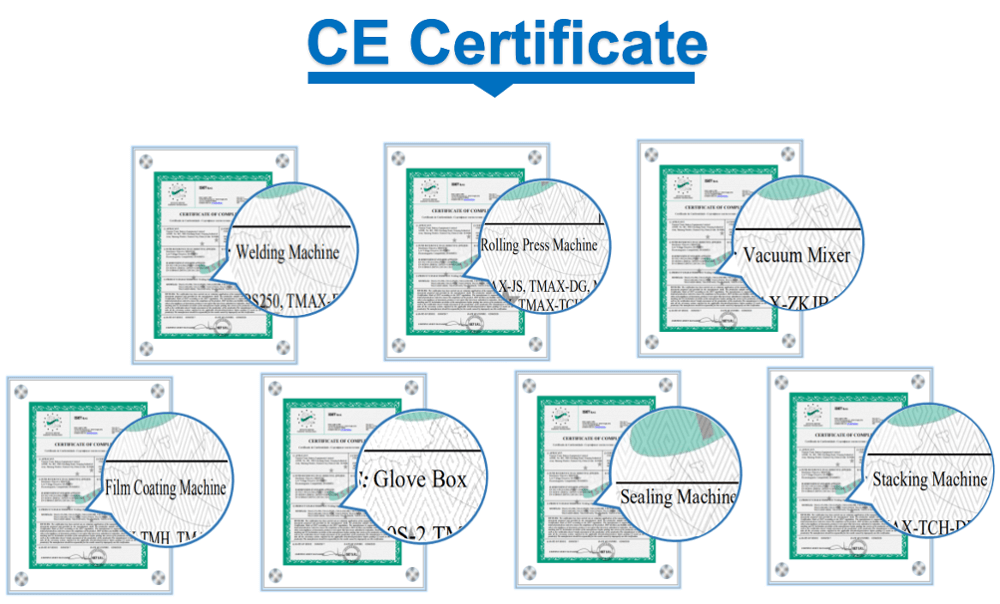

1Compliance:

CE CertifiedWarranty:

2 yearsDelivery Time:

5 daysEmail :

Louis@lithmachine.com

Roll-to-Roll Electrode Slitting Machine for Lithium Battery Manufacturing

This machine is used for the slitting and processing of lithium-ion battery electrode.

Applicable for slitting materials such as copper foil, aluminum foil, OPP, PE, PP, PVC, release paper, and release film.

This machine is a high-precision, high-sensitivity slitting device. Both rewinding and unwinding adopt high-precision air shafts. Tension is freely adjustable using a magnetic powder clutch. Web guiding is controlled by an automatic ultrasonic system with dual motor control.

The machine supports:

· Automatic detection

· Automatic web guiding

· Automatic length counting

· Anti-scratch protection for materials

· Auto-stop at preset lengths

· Fault alarms

Equipped with: 5 air knives

|

Item |

Specification |

|

Machine Model |

HC-520A |

|

Slitting Speed |

35 m/min |

|

Max. Web Width |

520 mm |

|

Min. Slitting Width |

30 mm |

|

Max. Unwind Diameter |

600 mm |

|

Max. Rewind Diameter |

450 mm |

|

Unwind Core Diameter |

76 mm (customizable) |

|

Rewind Core Diameter |

76 mm (customizable) |

|

Slitting Accuracy |

±0.2 mm |

|

Burr Accuracy |

≤30 μm |

|

Machine Weight |

Approx. 1300 kg |

|

Power Supply |

380V / 3 Phase / 50Hz |

|

Motor Power |

3 kW + 4 kW |

|

Compressed Air |

0.5–0.7 MPa / 120 L/min (user supplied), φ10 air pipe |

|

Machine Dimensions (L×W×H) |

Approx. 1600 × 1400 × 1200 mm |

|

No. |

Component |

Brand |

Remarks |

|

1 |

PLC |

Siemens (Germany) |

|

|

2 |

Touch Screen |

Weintek (Taiwan) |

|

|

3 |

Cylinder |

SMC |

|

|

4 |

Inverter |

Inovance |

2 units |

|

5 |

Main Motor |

Delta |

2 units |

|

6 |

Ultrasonic Web Guide |

Chongqing Bat |

|

|

7 |

Static Eliminator Bar |

Kodick |

|

|

Item |

Quantity |

Remarks |

|

Circlip Pliers |

1 |

|

|

Crescent Wrench |

1 |

|

|

Machine Foot Pads |

8 |

|

![]()

Power Processing→Power Grinding→Vacuum Mixing→Electrode Coating→Roll Press→Sheet Cutting→Vacuum Drying→Ultrasonic Welding→Electrode Winding→Spot Welding→Grooving→Glove Box→Electrolyte Injection→Electrode Diffusion→Hydraulic Sealing→Battery Analyzer

Related Machine

|

|

|

|

|

|

|

Electrode Slitting |

Welding Power: 80-6500W optional |

Lab cylindrical cell grooving machine |

Manual Sealing or Pneumatic Sealing Machine |

8 Channel Battery Tester

|

![]()

![]()

![]()

PACKAGE:

1 Standard exported package: Internal anticollision protection, external export wooden box packaging.

2 Shipping by express, by air, by sea according to customers' requirements to find the most suitable way.

3 Responsible for the damage during the shipping process, will change the damage part for you for free.

DELIVERY TIME:15-20 days after confirming order,detail delivery date should be decided according to production season and order quantity

ONLINE

ONLINE Louis@lithmachine.com

Louis@lithmachine.com +0086 15959378975

+0086 15959378975