- Language:

English ▼

English ▼

English ▼

English ▼ItemNo :

LITH-JRZX150MOQ :

1Warranty:

2 yearsDelivery Time:

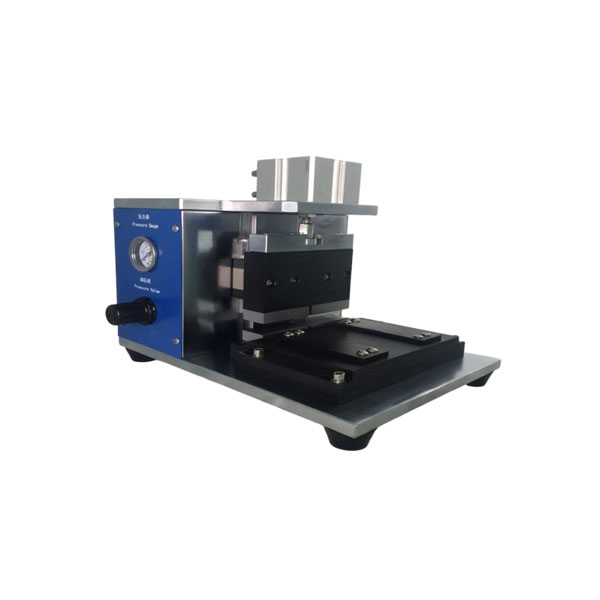

5 daysPouch Cell Tab Shaping Forming Machine

Application

The Pouch Cell Tab Shaping Forming Machine is purpose-built for thermally pressing and reshaping the tabs of stacked battery cells after they’ve been cut. It ensures tabs are flat and uniformly shaped, laying a solid foundation for subsequent processing steps.

Key Features

- HIWIN linear guide rails are incorporated to deliver precise guidance, ensuring the upper and lower dies press with consistent flatness.

- It offers easy operation, high working efficiency, stable temperature performance, and exceptional uniformity in tab forming results.

- Mold operation is powered by pneumatics, with auxiliary fixtures that assist in aligning and pressing the tabs accurately.

- A cell positioning tray is included to secure battery cells in the correct position during operation.

- The design is compact, reliable, and user-centric, making it easy to integrate into production lines.

- Pressing speed and forming time are adjustable, allowing for fine-tuning to achieve optimal process parameters.

Technical Specifications

|

Parameter |

Specification |

|

Applicable Cell Size |

Up to 150 × 150 mm |

|

Die Hardness |

≥ HRC58 |

|

Die Lifetime |

3 million cycles (before regrinding) |

|

Press Plate Material |

Imported S136 stainless steel, non-deforming and corrosion-resistant |

|

Forming Temperature |

Room temperature to 250 °C |

|

Distance Between Plates |

> 50 mm |

|

Operation Speed |

Up to 600 cycles/hour (air press) |

|

Air Source Requirement |

0.5–0.7 MPa |

|

Dimensions |

L230 × W200 × H250 mm |

|

Weight |

27 kg |

![]()

Pouch Cell Process: Tube Furnace/ Muffle Furnace→ Vacuum Mixing→ Electrode Coating→ Roll press→ Electrode Cutting→ Vacuum Drying→ Cases Forming→ Top&Side Sealing→ Electrolyte Filling→ Vacuum Sealing→ Battery Analyzer

For the pouch cell assembly, we also recommend you the following items:

![]()

![]()

![]()

1 Standard exported package: Internal anticollision protection, external export wooden box packaging.

2 Shipping by express, by air, by sea according to customers' requirements to find the most suitable way.

3 Responsible for the damage during the shipping process, will change the damaged part for you for free.

DELIVERY TIME:15-20 days after confirming the order, detail delivery date should be decided according to

production season and order quantity.

ONLINE

ONLINE +86 13174506016

+86 13174506016 Louis@lithmachine.com

Louis@lithmachine.com +86 18559646958

+86 18559646958

18659217588

18659217588