- Language:

English ▼

English ▼

English ▼

English ▼ItemNo :

LITH-JK-ZKHX-A3MOQ :

1Compliance:

CE CertifiedWarranty:

2 yearsDelivery Time:

5 days

Features

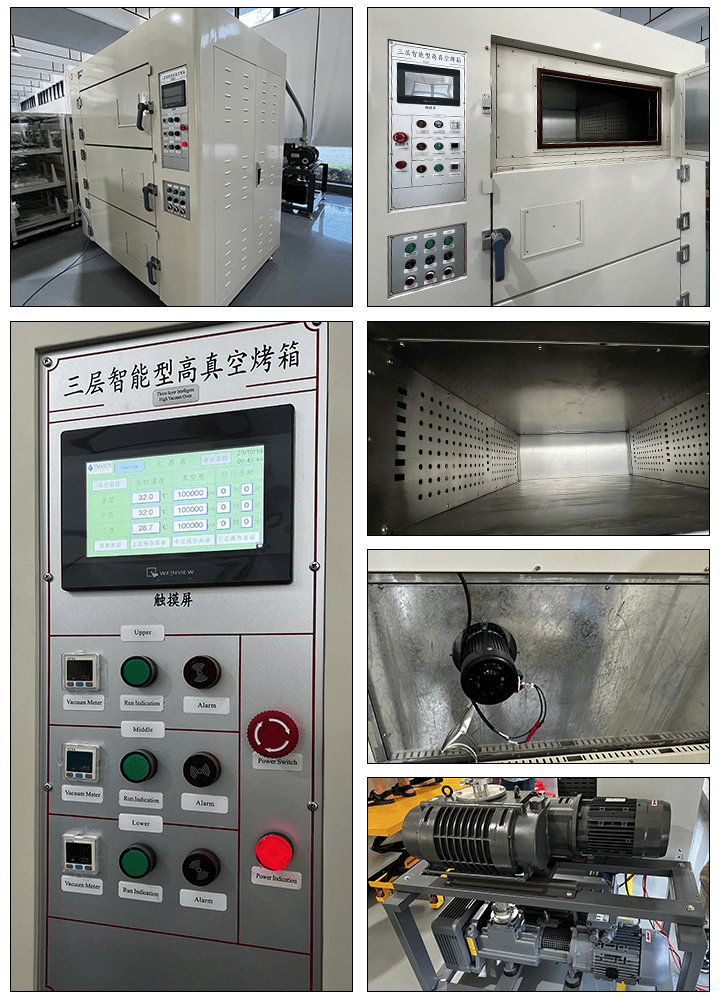

LITH-JK-ZKHX-A3 is mainly used with square vacuum chamber, can make full use of space. Pumping speed fast and efficient, high vacuum, easy to operate. Toughened bulletproof double glass observation window clearly the object of the working chamber. The tightness of the box can be adjusted, the overall shape of the silicon rubber gasket to ensure a high vacuum chamber. This product is suitable for the production process of electronic products off the bubble, dehydration, hardening and drying after cleaning treatment under vacuum heat treatment, the LED optical original lithium battery, and battery electrode,and so on, has a high reputation in the electric industry field.

Technology parameters

|

Parameter |

performance |

|

Description/model |

Battery special vacuum oven |

|

Workroom size |

height:300mm width: 800mm depth: 600mm*3 layers |

|

Outline size |

height:1850mm width:1420 mm depth: 890mm |

|

Working temperature |

room temperature :+15℃~200℃ |

|

The speed of risingtemperatur |

not more than 120 minutes when rising to the max.temperature |

|

Heating power |

4.5KW*3 |

|

Electrical supply |

Three- phases380V |

|

Outside material |

Cold-rolled plate,spay platics |

|

Color |

According to the customer’s color standard |

|

Working room material |

SUS304 stainless steel plate |

|

Stratified |

Multi |

|

Layer floor |

2 layer mesh partition / layer |

|

Exhaust connection |

back |

|

Open method |

Single-door, flexible double steel glass, with over pressure protection function |

|

Sealing ring |

silicone rubber ring with high temperature resistance, no connector |

|

Temperature instrumentation |

digital temperature controller |

|

Temperature control mode |

PID regulator |

|

Temperature accuracy |

±1℃ |

|

Temperature uniformity |

±5℃ |

|

Temperature Sensor |

PT100 |

|

Timing Control |

10 -hour timer, the alarm buzzer |

|

Over temperature protection |

over-temperature protection,when over the temperature, cut off the heating power and alarm buzzer |

|

Heating device |

Heating wire |

|

Vacuum |

100Pa, 6 hours pointer does not move ,12 hours to keep 98% , 24 hours to keep 95% |

|

Gas leakage |

≤300pa/h |

|

Remark |

three studios to work independently, independent heating, three sets of temperature control system, can work alone, can also work at the same time.Manual control vacuum switch, vacuum- sealed well when the power cut. The vacuum chamber can be individually, separately add nitrogen, without disturbing each other |

![]()

![]()

![]()

![]()

1 Standard exported package: Internal anticollision protection, external export wooden box packaging.

2 Shipping by express, by air, by sea according to customers' requirements to find the most suitable way.

3 Responsible for the damage during the shipping process, will change the damaged part for you for free.

DELIVERY TIME:15-20 days after confirming the order, detail delivery date should be decided according to

production season and order quantity.

ONLINE

ONLINE +86 13174506016

+86 13174506016 Louis@lithmachine.com

Louis@lithmachine.com +86 18559646958

+86 18559646958

18659217588

18659217588