ItemNo :

LITH-MC-E1MOQ :

1Place of Origin:

ChinaWarranty:

2 yearsDelivery Time:

5 days

Cylindrical Cell Assembly Pilot Lithium Battery Preparation Material For 18650 21700 26650 32650 Making

Features

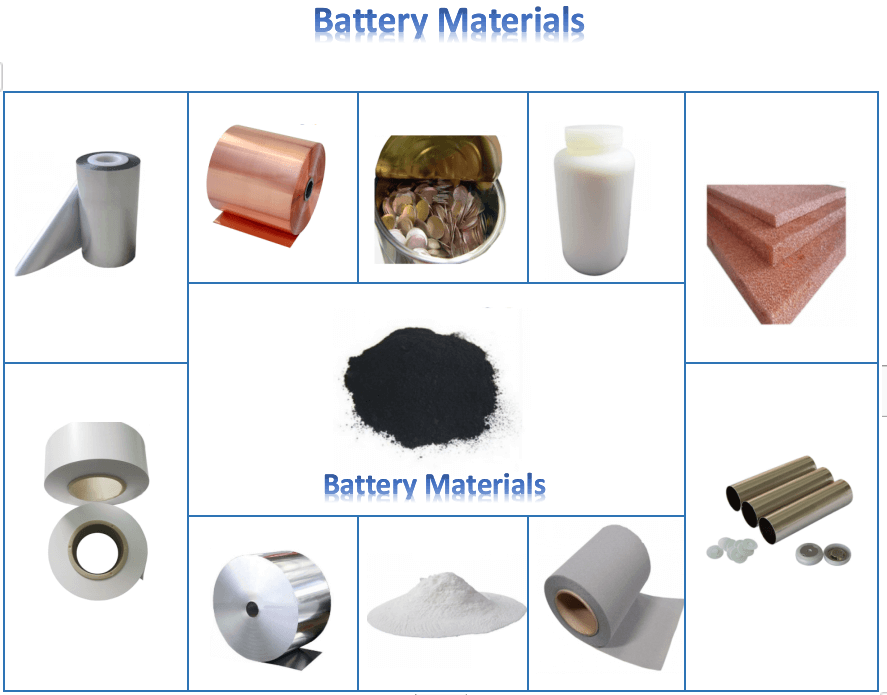

The main materials of lithium-ion battery include electrolyte, separator, anode and cathode materials, etc. The anode materials account for a large proportion (the mass ratio of anode and cathode materials is 3:1 ~ 4:1). Because the performance of anode materials directly affects the performance of lithium-ion batteries, the selection of high-quality battery materials plays a key role in batteries.

Specification

|

Type |

Product Name |

Main Features |

|

Cathode Material for Li-ion Battery |

LiCoO2 Powder

|

1. Formula:LiCoO2 2. Appearance: Black Powder 3. Molecular Weight:97.88 4. First Discharge Capacity (mA/g) : 145 @1C 5. Reasonable A-G Range: 6. 6. Anode has 5% ~10% more capacity than the cathode. 6. Voltage Range vs Li: 3V ~ 4.2V |

|

PVDF Binder

|

1. Purity:≥99.5% 2. standard specific gravity:1.74~1.77 3. Dielectric constant :4.50~5.50; 8.00~9.50 4. Melting Point:160-168 5. Melting Indix:1-2 6. Solubility:Transparent and dissolvable 7. Rotation Viscosity:≥2000 8. Intrinsic Viscosity :1.0-2.0 9. Moisture:≤ 0.1 |

|

|

NMP Solvent

|

1. The molecular 2. Purity:99.90% 3. Melting point: -24℃ 4. Boiling point: 202℃ 5. Density:1.028 g/ml 6. Refractive index:1.465-1.470 7. Flash point:95℃ |

|

|

Super Conductive Carbon Black Powder

|

1. BET Nitrogen surface area:62M2/g 2. Adsorption Stiffness Value (2):32Ml/5g 3. Moisture (as packed):0.1% 4. Density:160Kg/m3 5. Sulpher Content:0.02% 6. Iron(3):10ppm 7. Nickel:1ppm |

|

|

Aluminium Foil |

1. Thickness:9-19um 2. Standard width:200mm 3. Length:120m/roll (size can be customized according to request) |

|

|

|

Carbon Coated Aluminum Foil

|

1.Aluminum foil thickness:12-30um 2.Conductive coating single surface density(g/㎡/ side):0.5-2.0 g/㎡ 3.Double coating 4.Each side coating thickness is 1um |

|

Anode Material |

Graphite Powder |

1. Single Layer Graphene Oxide 2. Multilayer graphene oxide Single layer reduced graphene oxide 3. Reduced graphene oxide in a few layers (1-5 layers) 4. Multilayer reduced graphene oxide (6-10 layers) 5. Natural graphite 6. Conductive graphite |

|

High Purity Carboxymethyl Cellulose Powder CMC

|

1. Viscosity, mpa.s (2% aqueous solution):7000~10000 2. Purity:≥99.5% 3. Water content:≤10% 4. substituting degree:0.6~0.9 5. PH:6.0~8.5 6. heavy metal(pb), ppm:≤15 7. Fe, ppm:≤40 8. As, ppm:≤2 |

|

|

Copper Foil |

1.Thickness:9-15um 2.Standard width:200mm (Size can be customized according to request) |

|

|

Conductive Coating Copper Foil

|

1.Size:201*0.008mm 2.Length: 35m-40m 3.Cooper Foil width: 150mm 4.Double coating 5.Each side coating thickness is 1um |

|

|

SBR Styrene Butadiene Rubber |

1.Total solide (wt%):48~53 2. PH:5~7 3. Broofield viscosity (mPa.s):50~250 |

|

|

Other |

Cylindrical Battery Cases With Anti-Explosive Cap And Insulation O-Ring

|

1. Case are made of 304 stainless steel 2. Cap are made of Nickel plated steel 3. Seal O-ring are made of nylon(Optional) 4. Insulating gasket are made of PP |

|

Separator

|

PP PE Celgard Optional |

![]()

![]()

![]()

![]()

PACKAGE:

1 Standard exported package: Internal anticollision protection, external export wooden box packaging.

2 Shipping by express, by air, by sea according to customers' requirements to find the most suitable way.

3 Responsible for the damage during the shipping process, will change the damage part for you for free.

DELIVERY TIME:15-20 days after confirming order,detail delivery date should be decided according to production season and order quantity

ONLINE

ONLINE +86 13174506016

+86 13174506016 Louis@lithmachine.com

Louis@lithmachine.com +86 18659217588

+86 18659217588

18659217588

18659217588