ItemNo :

LITH-DCFS-200MOQ :

1Compliance:

Warranty:

2 yearsDelivery Time:

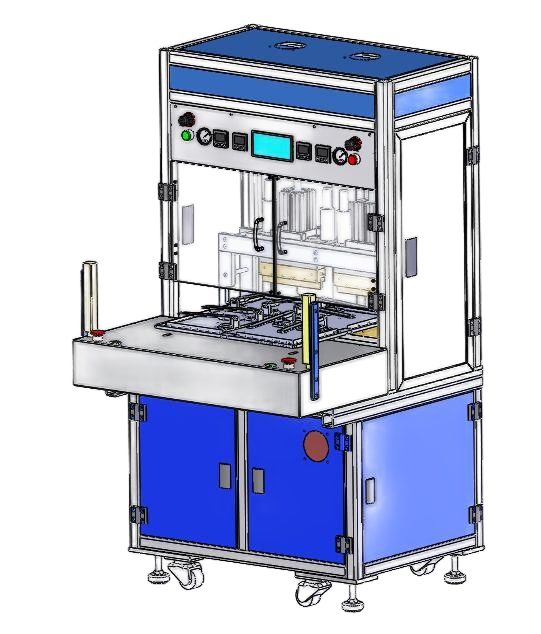

5 daysRotary-Type Automatic Top & Side Sealing Machine for Pouch Cells

l Function:

Performs thermal sealing on the top and side edges of square pouch lithium-ion cells, or top edge sealing for pouch cylindrical cells.

l Working Process:

Place the battery into the battery tray. Press the two control buttons on the front of the operation panel; the machine will automatically rotate the turntable to bring the battery into the sealing position. The lower and upper heat sealing bars will perform thermal sealing on the battery edge. After holding the pressure for the specified time, the heat sealing bars will return to their original positions. When the next battery enters, the previously sealed battery can be removed.

If no battery is placed in the tray, the corresponding upper and lower heat sealing bars will not operate.

l Standard Cell Size:

|

No. |

Symbol |

Dimension (mm) |

Diagram |

|

1 |

L |

100–200 |

|

|

2 |

W |

100–200 |

|

|

3 |

H |

3–15 |

|

Parameter |

Specification |

|

Power Supply |

220VAC / 50Hz |

|

Power Consumption |

4.5 kW |

|

Heating Rod Power |

500W each |

|

Compressed Air |

≥0.4 MPa |

|

Battery Tray Dimensions |

200 × 200 mm |

|

Applicable Cell Thickness |

≤15 mm |

|

Sealing Bar Length |

210 mm |

|

Sealing Bar Width |

Top Sealing: 3.5 mm soft sealing with preheating block for tab Side Sealing:5 mm hard sealing |

|

Heat Sealing Temperature |

< 250°C, adjustable |

|

Heat Sealing Speed |

≤400 cycles/hour (depending on process parameters) |

|

Equipment Weight |

Approx. 330 kg |

|

Overall Dimensions (L×W×H) |

Approx. 860 × 860 × 1650 mm |

|

Coating Color |

Customized according to customer requirements |

1. Rotary 4-station structure, with two sets of heat sealing heads

2. Top and side sealing temperatures (ambient ~250°C) are independently adjustable

3. For square pouch cells, top and side sealing can be performed simultaneously. Both soft and hard sealing processes can be achieved by changing the sealing strips

4. Touchscreen display operation, controlled by PLC

5. Top and side sealing pressures and cylinder strokes are independently adjustable

6. Top and side sealing times (0–99.9 seconds) are independently adjustable

7. The front of the machine is equipped with a safety light curtain. If a body enters during operation, the machine will immediately reset automatically—safe and reliable

1. Overall sheet metal appearance must be precisely finished, no paint loss or damage, seams must be uniform. All screws must be stainless steel hex socket, hinges must be silver stainless steel

2. Acrylic panels must be free from cracking, scratches, or scuffs

3. Aluminum profiles must be free from cracking, scratches, or scuffs

4. Electroplated parts must be rust-free, scratch-free, scuff-free; plating thickness must be above 5μm

5. All machined parts must undergo surface treatment, such as foot support plates, aluminum profile support blocks, and voltage pressing blocks

|

No. |

Name |

Quantity |

Brand |

Remarks |

|

1 |

Cylinder |

4 |

AIRTAC |

|

|

2 |

Solenoid Valve |

4 |

AIRTAC |

|

|

3 |

PLC |

1 |

Panasonic |

|

|

4 |

Touchscreen |

1 |

Weintek |

|

|

5 |

Temperature Controller |

4 |

OMRON |

|

|

6 |

Pressure Regulating Valve |

1 |

AIRTAC |

|

|

7 |

Safety Light Curtain |

1 |

LCP |

|

|

8 |

Electrical Components |

Batch |

CHINT |

|

|

No. |

Name |

Quantity |

Unit |

Remarks |

|

1 |

Operation Manual (Chinese) |

1 |

Set |

|

|

2 |

Packing List |

1 |

Set |

|

|

3 |

Complete Front View Diagram |

1 |

Set |

|

|

4 |

Electrical Schematic Diagram |

1 |

Set |

|

|

5 |

Main Components Specification List |

1 |

Set |

|

|

No. |

Name |

Specification/Model |

Quantity |

Manufacturer |

Remarks |

|

1 |

Toolbox |

— |

1 set |

— |

|

|

2 |

Heating Rod |

¢9.8 × 210 |

2 |

— |

|

|

3 |

Thermocouple |

— |

1 |

— |

|

|

4 |

Solid State Relay |

— |

2 |

— |

|

|

5 |

Fuse |

— |

2 |

— |

|

Pouch Cell Process: Tube Furnace/ Muffle Furnace→ Vacuum Mixing→ Electrode Coating→ Roll press→ Electrode Cutting→ Vacuum Drying→ Cases Forming→ Top&Side Sealing→ Electrolyte Filling→ Vacuum Sealing→ Battery Analyzer

For the pouch cell assembly, we also recommend you the following items:

![]()

![]()

![]()

PACKAGE:

1 Standard exported package: Internal anticollision protection, external export wooden box packaging.

2 Shipping by express, by air, by sea according to customers' requirements to find the most suitable way.

3 Responsible for the damage during the shipping process, will change the damaged part for you for free.

DELIVERY TIME:15-20 days after confirming the order, detail delivery date should be decided according to

production season and order quantity.

ONLINE

ONLINE +86 13174506016

+86 13174506016 Louis@lithmachine.com

Louis@lithmachine.com +86 18659217588

+86 18659217588 18659217588

18659217588