- Language:

English ▼

English ▼

English ▼

English ▼ItemNo :

LITH-DZF-6020MOQ :

1Compliance:

CE CertifiedWarranty:

1 yearDelivery Time:

5 days

Vacuum Ovens combine forced-air circulation and programmable temperature controller to achieve dependable, uniform furnace for a variety of laboratory applications like drying, storing, annealing. It is an ideal heating equipment for material R&D laboratories.

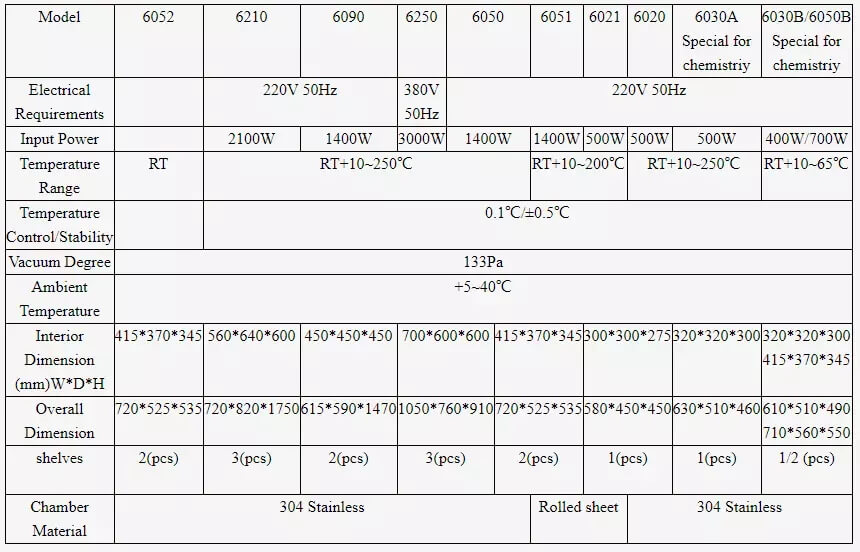

Specifications

Structure

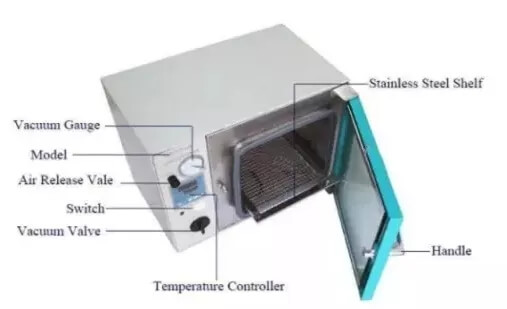

1. The chamber is structured with stainless steel and welded to bracing pieces.

2. The inner Chamber size: 300 mm x 300 mm x 275 mm (12 x 12 x 12", 25 Liter)

Working Voltage

AC 108 - 240 V 50/60 Hz

Power Consumption

600W

Heating Rates

RT-80°C, less than 20 minutes (unloaded)

Thermocouple

K type

Working Temperature

RT+10 ~ 200°C for the continuous use

Temperature Controller

1. Single point temperature setting

2. Built-in over-temperature protection

3. PID precise temperature control

4. Temperature control accuracy: +/-0.1°C

5. Temperature uniformity: +/-5°C @ 100°C, 25" Hg at center 6"x 6" area only

Vacuum Pump (optional)

Ultimate Vacuum Level: 1000 millitorrs.

Warranty

Two years limited warranty with lifetime technical support

Application Notes

Such an oven is an excellent tool for the larger volume of battery electrode drying.

3. A good vacuum sealing is achieved by the silicone gasket and the positive latch door.

4. The double layers observation window consists of 1/2" tempered glass and transparent polycarbonate shield.

5. Two stainless steel shelves are included to facilitate processing efficiency.

![]()

Related Machine (Click the pictures to check more details)

Power Processing→Power Grinding→Vacuum Mixing→Electrode Coating→Roll Press→Sheet Cutting→Vacuum Drying→Ultrasonic Welding→Electrode Winding→Spot Welding→Grooving→Glove Box→Electrolyte Injection→Electrode Diffusion→Hydraulic Sealing→Battery Analyzer

|

|

|

|

|

|

|

Electrode Slitting |

Welding Power: 80-6500W optional |

Lab cylindrical cell grooving machine |

Manual Sealing or Pneumatic Sealing Machine |

8 Channel Battery Tester

|

Coin Cell Process:

Materilas → Powder Processing →Powder Grinding Mill → Vacuum Mixing → Electrode Coating → Roll Press → Vacuum Drying → Disc Cutter → Electrolyte Injection → Crimping Machine → Battery Analyzer

For the coin cell Assembly, we also recommend you the following items:

![]()

![]()

![]()

PACKAGE:

1 Standard exported package: Internal anticollision protection, external export wooden box packaging.

2 Shipping by express, by air, by sea according to customers' requirements to find the most suitable way.

3 Responsible for the damage during the shipping process, will change the damage part for you for free.

DELIVERY TIME:15-20 days after confirming order,detail delivery date should be decided according to production season and order quantity

ONLINE

ONLINE +86 13174506016

+86 13174506016 Louis@lithmachine.com

Louis@lithmachine.com +86 18559646958

+86 18559646958

18659217588

18659217588