- Language:

English ▼

English ▼

English ▼

English ▼ItemNo :

LITH-MSK-MQ280MOQ :

1Warranty:

2 yearsDelivery Time:

5 daysHigh Precision Battery Electrode Die Cutter Machine For Pouch Cell

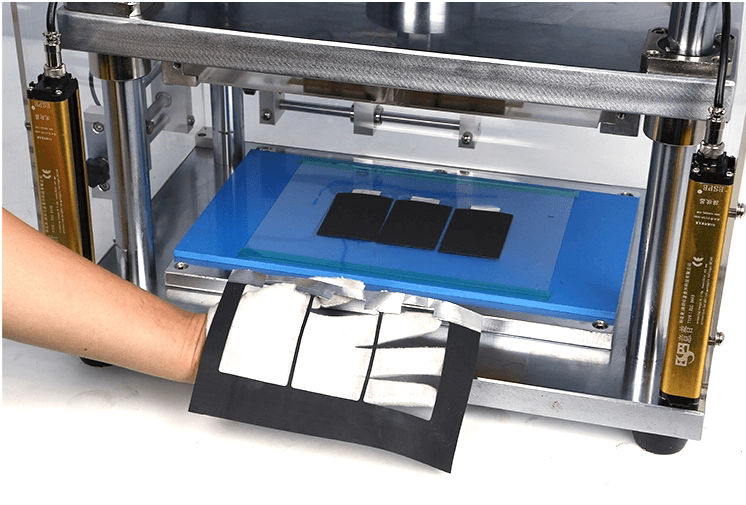

LITH-MQ280 is a CE Certified Precision electrode die cutter with optional size range). It is a necessary tool in the production line of pouch cell to produce specific shapes of cathodes and anodes with current collector tabs. The size of the electrodes it cuts perfectly matches the standard pouches made by the LITH-SCK200 cup forming machine, and the shape of the electrodes it produces is also handy for the latter processing steps. The IR sensor (Safety Curtain) built in the front of the machine ensures operation safety when electrode sheets are fed from the front.

SPECIFICATIONS:

|

Working Table Area |

300mm(L) x 250mm(W) |

|

Customized size die is available upon |

New: Two standard electrodes (Cathode & Anode) cutting dies are included for immediate use. 2 pcs of electrodes can be produced per cut. 1. Cathode Die: 57mm (L) x 44mm (W). With 10mm (L) x 10mm (W) protrude current collector. 2. Anode Die: 58mm (L) x 45mm (W). With 10mm (L) x 10mm (W) protrude current collector 3. Customized dies with Max. area 280 x 180 mm, available at extra cost. 4. Customized dies with Max. 8 pcs of electrodes can be produced per cut. |

|

Working Voltage |

AC 110V or 220V 50/60 Hz, single phase |

|

Max. Power Consumption |

100W |

|

Cutting Accuracy |

±0.1mm |

|

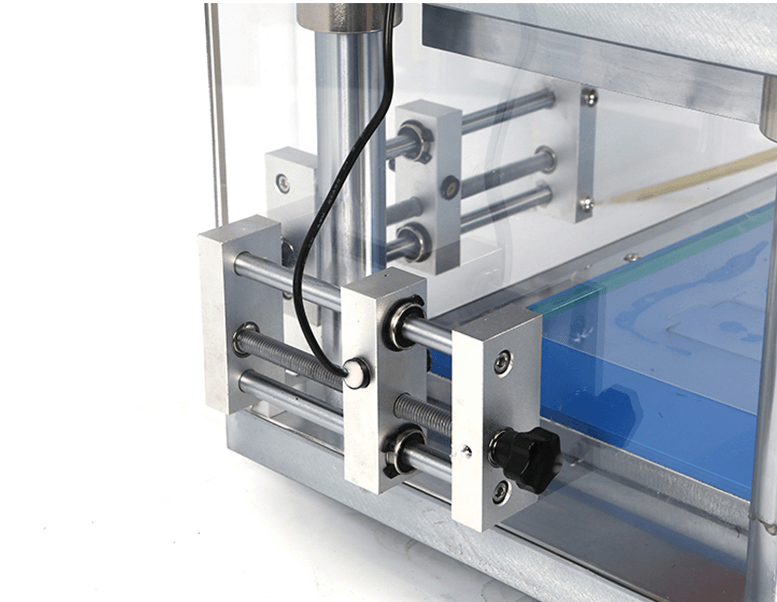

Air Cylinder |

3 tons Max. pressure |

|

Tensile Cylinder |

0.15 tons pressure |

|

Feeding |

Manually |

|

Production Yield |

800 - 2000 pieces of electrodes per hour |

|

Product Dimensions |

L580xW455xH900mm |

|

Net Weight |

120kg |

|

Compliance |

CE Certificate |

|

Warranty |

One Year limited warranty with lifetime support |

|

Air Pressure |

Recommend 60 psi |

![]()

Pouch Cell Process: Tube Furnace/ Muffle Furnace→ Vacuum Mixing→ Electrode Coating→ Roll press→ Electrode Cutting→ Vacuum Drying→ Cases Forming→ Top&Side Sealing→ Electrolyte Filling→ Vacuum Sealing→ Battery Analyzer

For the pouch cell assembly, we also recommend you the following items:

![]()

![]()

![]()

1 Standard exported package: Internal anticollision protection, external export wooden box packaging.

2 Shipping by express, by air, by sea according to customers' requirements to find the most suitable way.

3 Responsible for the damage during the shipping process, will change the damaged part for you for free.

DELIVERY TIME:15-20 days after confirming the order, detail delivery date should be decided according to

production season and order quantity.

ONLINE

ONLINE +86 13174506016

+86 13174506016 Louis@lithmachine.com

Louis@lithmachine.com +86 18559646958

+86 18559646958

18659217588

18659217588