- Language:

English ▼

English ▼

English ▼

English ▼ItemNo :

LITH-ECSMOQ :

1Warranty:

2yearsDelivery Time:

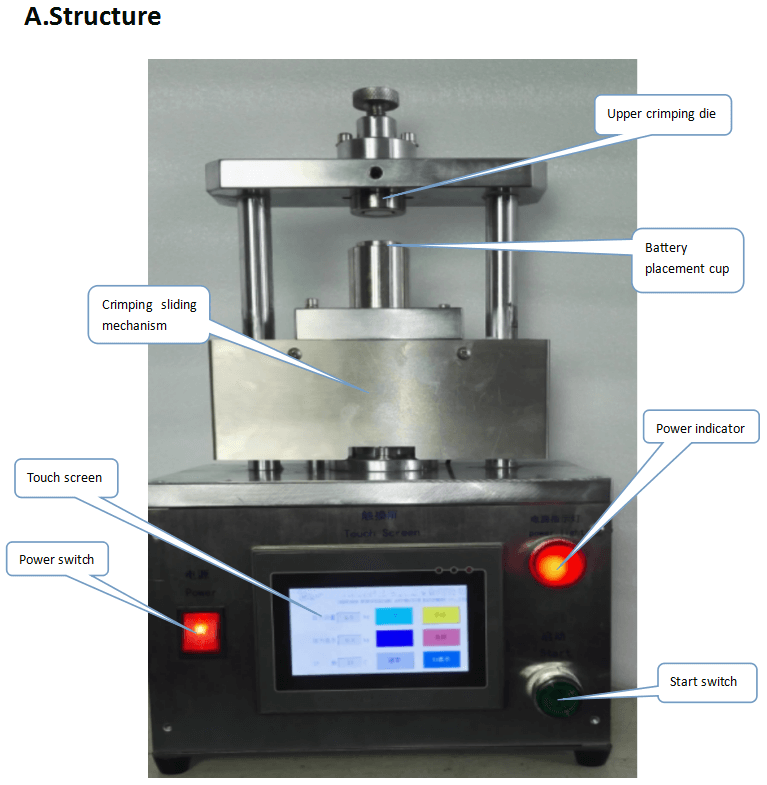

5 daysElectric Coin Cell Crimping Machine for Button Cell Preparation

Features

LITH-SF120 is a new design and CE Certified coin cell crimper with lighter weight and a smaller footprint. The crimper is suitable for sealing various types of coin cells such as CR2032,CR2025,and CR2016 with included die. It can also crimp CR2325, CR2450, AG3, AG5 and other special size cases with optional die sets.

Technical Parameter

| Power | 110 - 240V AC 50/60Hz for universal use |

| 24V DC motor with reducing gear, 20W | |

| Die Set & Compatibility | Assembling dies for crimping CR2032, CR2025, & CR2016 coin |

| cells (Optional CR2325, CR2450 die sets are available upon request). | |

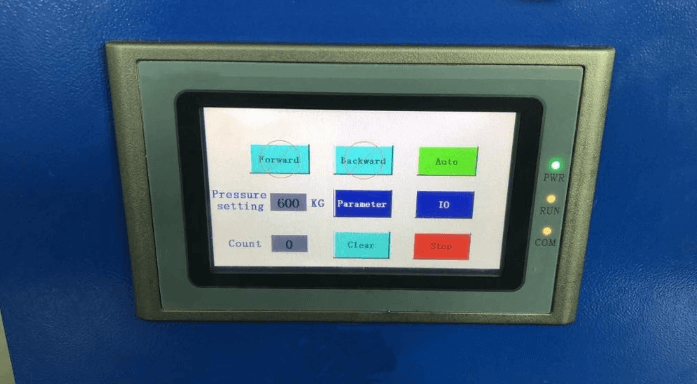

| Pressure | 1. The pressure applied to seal the cell case is pre-set to a |

| constant pressure at about 800 kg before shipping. | |

| 2. Pressure adjustment knob at the top can be used to adjust | |

| the pressure applied to the negative cap of the cell to prevent | |

| case deformation. | |

| Structure | Heavy Duty Steel Platform |

| Protection Shield | Protection shield / enclosure (plexiglass) with safety interlock is |

| installed | |

| Product Dimensions | 250mm(L) x 150mm(W) x 450mm(H) |

| Compliance | CE |

| Warranty | Two years limited warranty with lifetime support |

| Maintenance Notes & Warnings | |

| 1. Electrolytes are highly corrosive materials.The die set must be | |

| cleaned with alcohol after each use to avoid corrosion | |

| 2. The PTFE die (found at the top die) ejects the cell casing after | |

| crimping via spring loaded pressure. Do NOT over tighten the | |

| pressure adjustment knob to avoid damaging this PTFE die. | |

| 3.To set the proper pressure on the die, loosen the knob all the way | |

| until the spring compression is no longer stressed. Then start tightening the knob and stop turning it once the | |

| spring compression is felt. | |

| 4.This will prevent the PTFE die from becoming deformed by being | |

| subjected to excessive pressure. | |

| Net Weight | 32 kg |

| Shipping Weight | 46 kg |

![]()

Coin Cell Process:

Materilas → Powder Processing →Powder Grinding Mill → Vacuum Mixing → Electrode Coating → Roll Press → Vacuum Drying → Disc Cutter → Electrolyte Injection → Crimping Machine → Battery Analyzer

For the coin cell Assembly, we also recommend you the following items:

![]()

![]()

![]()

1 Standard exported package: Internal anticollision protection, external export wooden box packaging.

2 Shipping by express, by air, by sea according to customers' requirements to find the most suitable way.

3 Responsible for the damage during the shipping process, will change the damaged part for you for free.

DELIVERY TIME:15-20 days after confirming the order, detail delivery date should be decided according to

production season and order quantity.

ONLINE

ONLINE +86 13174506016

+86 13174506016 Louis@lithmachine.com

Louis@lithmachine.com +86 18559646958

+86 18559646958

18659217588

18659217588