- Language:

English ▼

English ▼

English ▼

English ▼ItemNo :

LITH-ZTH-04MOQ :

1Delivery Time:

5 days

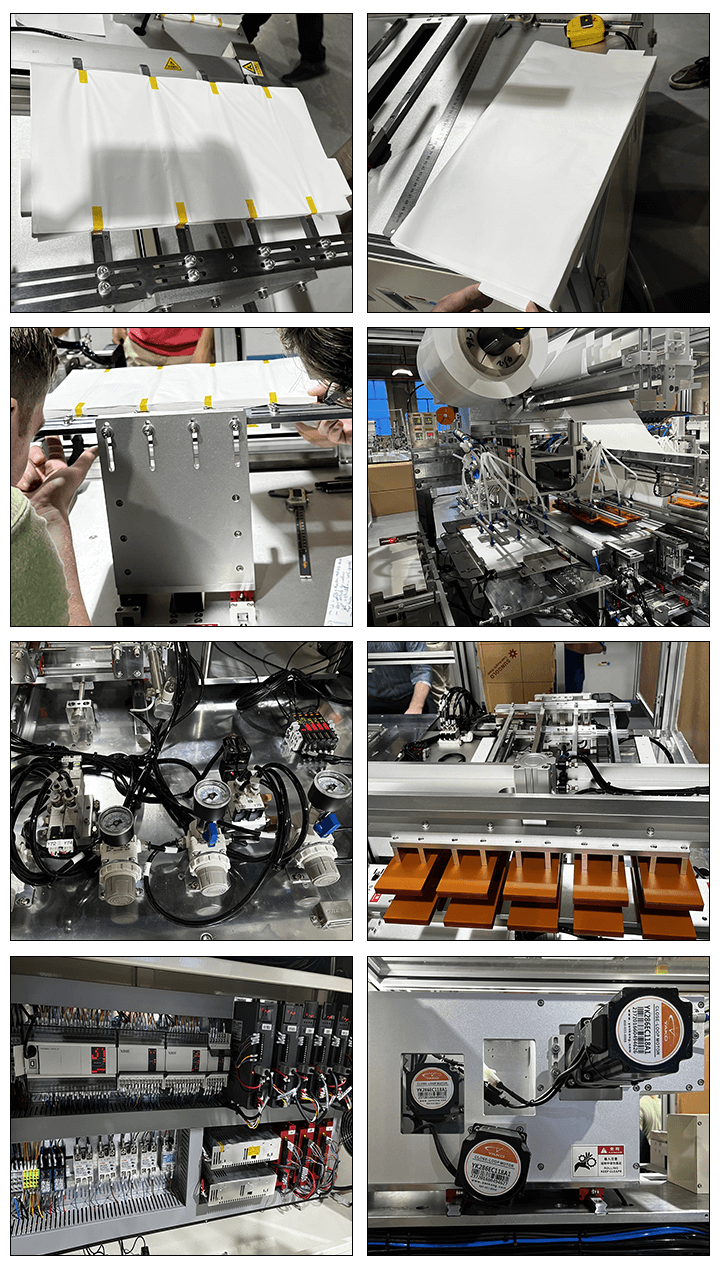

Dual-Workstation Stacking Machine For Pouch Battery Production

Feature

1.High precision: By accurately positioning the electrode plates, the overall position accuracy of the electrode plates during lamination is ensured to be ± 0.3mm

2.Diaphragm accuracy: active unwinding, floating wheel tensioning of the diaphragm, overall module correction, electrostatic removal of the diaphragm, and diaphragm alignment accuracy of ± 0.2mm,

3.Dust control: material box and secondary positioning are equipped with effective dust suction mechanism; The suction cup and rod are made of non-metallic materials; Positive and negative electrode material boxes, secondary positioning, and 4.intermediate isolation treatment to prevent cross contamination of positive and negative electrode materials.

5.Multiple sheet leakage measures: material box swing, sheet separation brush, robotic arm servo shaking plate separation pole plate, ultrasonic sensor detection of multiple sheet leakage.

6.Corner detection of electrode lug: four Corner detection detection and lug detection of electrode lug to prevent the electrode lug from missing angle or folded angle from overlapping into the electric core.

Specification

|

Locate mode |

Mechanical positioning or CCD positioning |

|

Stacking efficiency |

Single station 1.0-1.2 (complete machine 0.5-0.6) s/pcs |

|

Auxiliary time |

<10s |

|

Alignment accuracy between electrode and diaphragm |

Center deviation ± 0.3mm |

|

Diaphragm end face alignment accuracy |

±0.3mm |

|

Adjacent pole alignment accuracy |

±0.2mm |

|

Overall alignment accuracy of polar plates |

±0.3mm |

|

Number of laminations |

Can be set within the thickness adaptation range |

|

Outer diaphragm |

Tail roll/no tail roll |

|

Pass rate |

≥99.5% |

|

Utilization rate |

≥98% |

|

Overall dimensions |

W4000mm x L2000mmx H2350mm |

|

Weight/bearing capacity |

About 5000Kg ; >650Kg/M2 |

|

Power |

AC220V single-phase; 10% voltage wave induced soil disturbance; Power: 8KW; Frequency: 50Hz |

|

Compressed air |

0.5~0.7Mpa (5~7kgf/cm2 ), dosage 400L/min |

|

Thickness |

5~20mm |

|

|

Width |

80~200mm |

|

|

Length |

120~300mm |

|

|

Pole length |

10~30mm |

|

|

Polar direction |

On the same/opposite side |

Production Assembly Plant

![]()

![]()

![]()

![]()

PACKAGE:

1 Standard exported package: Internal anticollision protection, external export wooden box packaging.

2 Shipping by express, by air, by sea according to customers' requirements to find the most suitable way.

3 Responsible for the damage during the shipping process, will change the damaged part for you for free.

DELIVERY TIME:15-20 days after confirming the order, detail delivery date should be decided according to

production season and order quantity.

ONLINE

ONLINE +86 13174506016

+86 13174506016 Louis@lithmachine.com

Louis@lithmachine.com +86 18559646958

+86 18559646958

18659217588

18659217588