ItemNo :

LITH-ZTH-01MOQ :

1Delivery Time:

5 days

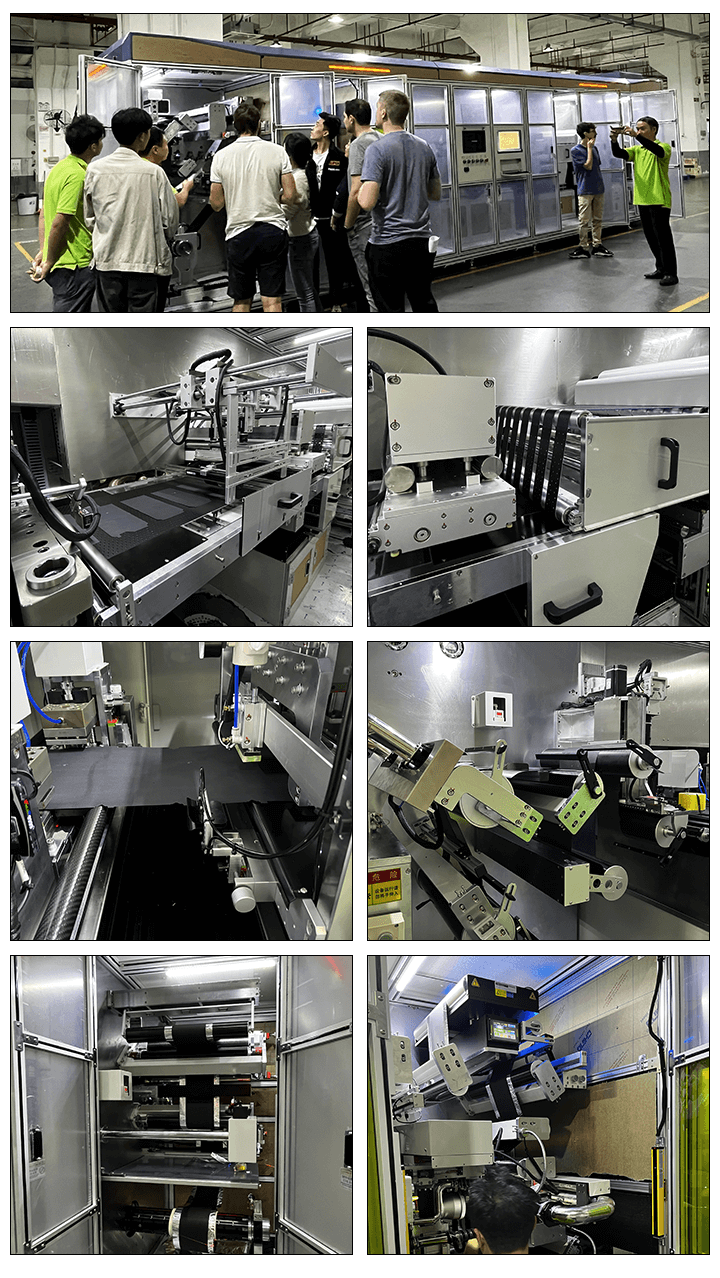

Automatic High-Speed Coating and Die Cutting Machine For Pouch Cells Production

Feature

7)FFU fans on the top of the equipment provide air supply, while an industrial dust removal system creates negative pressure suction at multiple stations

Specification

|

Project |

Parameter |

|

Production efficiency |

>250PPM (electrode width 100-160mm) |

|

Burr size |

Vas12um ; Vbs12um |

|

Deviation correction accuracy |

≤±0.1mm |

|

Slice forming accuracy |

±0.2mm |

|

Mold Life |

1. After each mold repair, it can be used no less than 1.5 million times; 2. The number of times the mold can be repaired ≥ 10 times; |

|

Material box receiving accuracy |

±0.5mm |

|

Qualification rate |

≥ 99.8% (defects caused solely by the machine) |

|

Crop growth rate |

≥ 98% (faults caused solely by the machine) |

|

Overall dimensions |

W1750mm x L7000mm x H2350mm |

|

Weight/bearing capacity |

About 8000kg; >650Kg/M-2 |

|

Power |

AC380V three-phase; Voltage fluctuation ± 10%; Power: 30KW; Frequency: 50Hz |

|

Compressed air |

0.5-0.7Mpa (5-7kgf/cm2), dosage 200L/min |

|

Project |

Parameter |

|

|

Punching method |

Metal mold punching |

|

|

Material system |

Continuous coating of electrode sheet coil material after slitting, with one side outlet lug |

|

|

Roll diameter |

≤ medium 800mm |

|

|

Inner diameter of drum |

3"/6" |

|

|

Pole winding error |

士3mm |

|

|

Snake shaped bending error of polar plate |

±1mm/m |

|

|

Height difference of polar wave edge |

<2mm |

|

|

Pole width W |

60~200mm |

|

|

Pole length L |

80~300mm |

|

|

Pole ear length H |

10~30mm |

|

|

Pole ear edge distance Q |

5-20mm |

|

|

Pole ear width P |

10~50mm |

|

|

Pole ear belt material X |

0~2mm |

|

|

Round RB |

2~5mm |

|

|

Round corners RA |

Inner rounded corner |

Outer rounded corner |

Production Assembly Plant

![]()

![]()

![]()

![]()

PACKAGE:

1 Standard exported package: Internal anticollision protection, external export wooden box packaging.

2 Shipping by express, by air, by sea according to customers' requirements to find the most suitable way.

3 Responsible for the damage during the shipping process, will change the damaged part for you for free.

DELIVERY TIME:15-20 days after confirming the order, detail delivery date should be decided according to

production season and order quantity.

ONLINE

ONLINE +86 13174506016

+86 13174506016 Louis@lithmachine.com

Louis@lithmachine.com +86 18559646958

+86 18559646958

18659217588

18659217588