- Language:

English ▼

English ▼

English ▼

English ▼ItemNo :

LITH-H200TMOQ :

1Warranty:

2yearsDelivery Time:

5 daysVacuum Aluminium Plate Touch Screen 200C Heating and Drying Film Coating Machine For Battery Electrode

Specifications

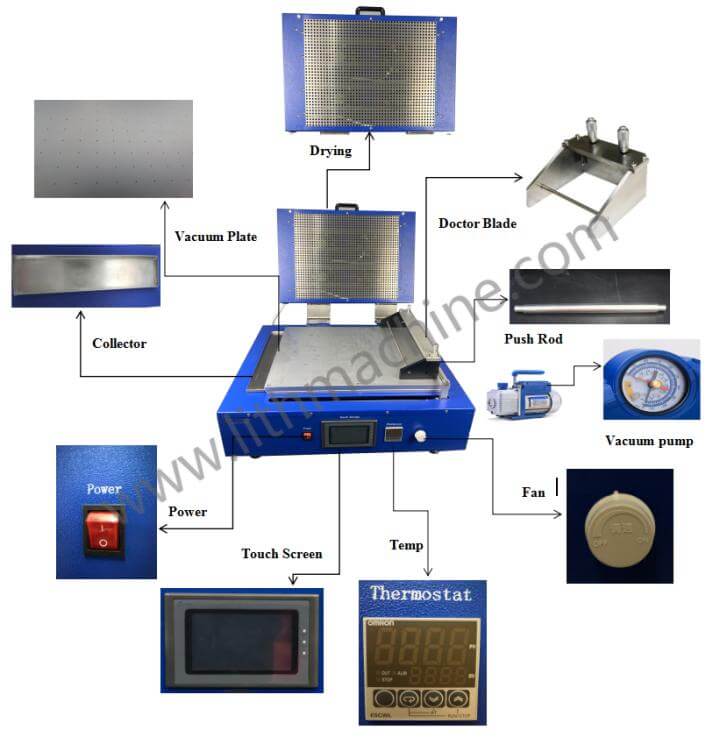

LITH-H200T is an NRTL standard Compact Tape Casting Coater with the vacuum chuck hotplate up to200ºC and the active carbon filter on the top cover to protect lab environment. It is an excellent tool to make high-temperature polymer coating or conductive ceramic film on various substrates.

Power

· 110V AC 50/60Hz

· 1500W

Heatable Vacuum Platform

· Vacuum chuck made of aluminum alloy with micro-size hole

· Vacuum chuck Area: 250mm(W) x 400 mm(L) ( 10"W x 17" L )

· Heating elements are installed inside chuck which can reach 200ºC Max.

· Precision digital temperature controller with +/- 1ºC accuracy

Vacuum Pump (Optional)

· A vacuum pump is required(Included)

Film Applicator

·Built in pushing bar for using micrometer adjustable applicator.

·200 mm width Applicator with micrometer adjustable head is included for immediate use

·24VDC motor driven the pushing bar continuously to the adjustable position, which can be used under Ar gas glovebox.

Note: Thinnest film can be achieved is > 10 micron

Max. Coating Area

· 350mm(L) x 200mm(W) (Can be customized)

Accuracy of Film thickness

· +/- 0.01mm

Traverse Speed & Distance

· Travel Speed: 0 - 80mm/sec variable

· Travel distance: 0 - 400 mm adjustable

Top Cover and Filter

· Active carbon filter and venting fan are installed on the top cover

· The filter will remove organic vapor to make lab environmental safe & clean

![]()

Coin Cell Process:

Materilas → Powder Processing →Powder Grinding Mill → Vacuum Mixing → Electrode Coating → Roll Press → Vacuum Drying → Disc Cutter → Electrolyte Injection → Crimping Machine → Battery Analyzer

For the coin cell Assembly, we also recommend you the following items:

![]()

![]()

![]()

1 Standard exported package: Internal anticollision protection, external export wooden box packaging.

2 Shipping by express, by air, by sea according to customers' requirements to find the most suitable way.

3 Responsible for the damage during the shipping process, will change the damaged part for you for free.

DELIVERY TIME:15-20 days after confirming the order, detail delivery date should be decided according to

production season and order quantity.

ONLINE

ONLINE +86 13174506016

+86 13174506016 Louis@lithmachine.com

Louis@lithmachine.com +86 18559646958

+86 18559646958

18659217588

18659217588