- Language:

English ▼

English ▼

English ▼

English ▼ItemNo :

Lith-KJ12UHMOQ :

1Compliance:

CE CertifiedWarranty:

1 yearDelivery Time:

5 days

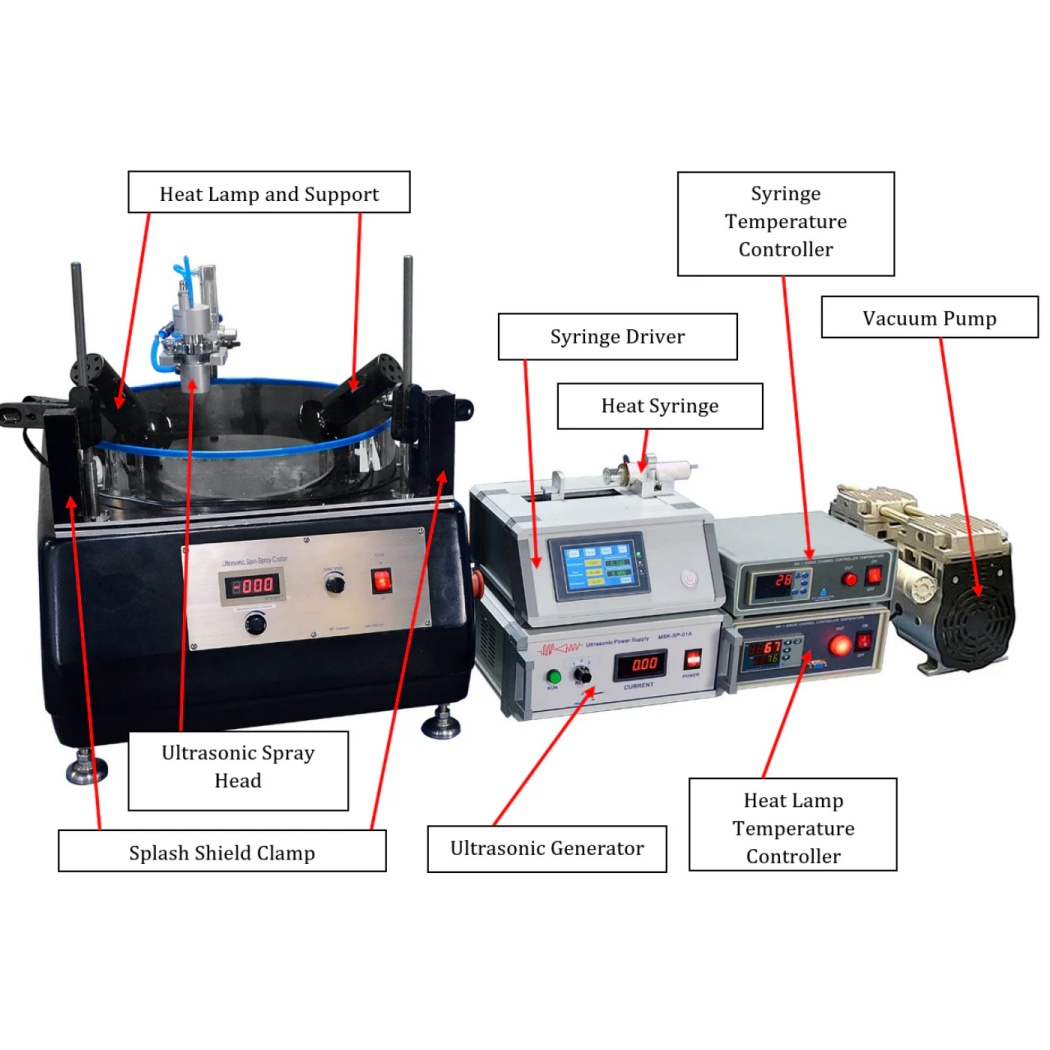

Ultrasonic Spin-Spray Coater for 12" Wafers With Heating Function

TMAX-KJ12UH is a cost-effective ultrasonic Spin-Spray Coater for liquid-phase, ultra-uniform coating process on large substrates up to 12". The system consists of (1) a 12" spin coater with vacuum chuck, (2) a compressed air-assisted ultrasonic spray nozzle mounted on a swing arm, (3) a heatable syringe pump, and (4) a heat lamp system for substrate heating. It can also function as an atmospheric mist CVD system.

· Combines the benefits of spin and spray coating, enabling dense and uniform liquid-phase deposition on large substrates.

· Applications include:

1. Low-temperature precipitation (e.g., RF/microwave ferrites deposition)

2. Polymer coating

3. Powder and composite material coating

4. Coating on patterned/uneven substrates

· Operates in spin-only, spray-only, or combined modes.

· Vacuum chuck with adjustable substrate holders for flat substrates up to 12" diameter or 8" square.

· Includes one oil-less pump for the vacuum chuck, controlled by the spin coater.

· Spin speed: 300–3000 rpm (adjustable).

o Safety note: For substrates larger than 8", speed should be limited to 2000 rpm.

· Includes one ultrasonic generator with two ultrasonic spray nozzles (compressed air shaper included).

· Two spray nozzles with KF-25 adapter:

o Cylindrical type: Narrower spray (~20 mm diameter).

o Cone type: Wider spray (~40 mm diameter).

· Recommended compressed air pressure for aqueous solutions: ~2 psi.

· Integrated flow meter for regulating/monitoring compressed airflow.

· Fluid viscosity range: 1–100 mPa·s (cP).

· Swing arm for mounting the ultrasonic spray head (adjustable speed and movement range).

· Optional: Low-cost compressive gas atomizing nozzle (available upon request).

· Includes an LCD touch screen-controlled heatable syringe pump for liquid delivery to the ultrasonic nozzle.

· Comes with one 20 mL syringe (compatible with syringes of 0.4–30 mm diameter).

· Pumping rate: 0.001–20 mm/min (adjustable).

· Built-in flexible Polyimide heater with 30-segment programmable temperature controller (up to 75°C).

· Optional: Dual heat lamps (max. 1000 W, up to 80°C) with thermocouple and temperature controller for radiative substrate heating (up to 65°C on 12" metal substrates).

· Fume hood recommended for health/safety compliance.

· Compressive gas atomizing spray nozzle available for NRTL certification (see Pic. 2).

· Customized multi-spray head (available upon request; see Pic. 3).

· Power: 208–240 VAC, 50/60 Hz, 3000 W total.

· Gas: ~2 psi compressed air for the ultrasonic nozzle (air compressors available for order).

o Critical note: If using a gas cylinder instead of an air compressor (Pic. 2), a two-stage pressure regulator (Pic. 1) must be installed to limit pressure for safe operation.

· Net weight: 160 lbs.

· Shipping weight/dimensions:

1. 425 lbs, 48"×40"×42"

2. 255 lbs, 48"×40"×40"

3. 155 lbs, 48"×40"×35"

· CE Certified.

· 1-year limited warranty with lifetime support.

· Mandatory: Process must be conducted in a fume hood (see Optional section) with proper exhaust handling.

· Do not overfill the water bowl/base with liquid—excess liquid may leak into the motor shaft. Use a fabric cloth to wipe residues.

· For optimal coating quality, pre-clean substrates with a plasma cleaner (reduces surface tension; see pictures for details).

![]()

![]()

![]()

![]()

PACKAGE:

1 Standard exported package: Internal anticollision protection, external export wooden box packaging.

2 Shipping by express, by air, by sea according to customers' requirements to find the most suitable way.

3 Responsible for the damage during the shipping process, will change the damaged part for you for free.

DELIVERY TIME:15-20 days after confirming the order, detail delivery date should be decided according to

production season and order quantity.

ONLINE

ONLINE +86 13174506016

+86 13174506016 Louis@lithmachine.com

Louis@lithmachine.com +86 18559646958

+86 18559646958

18659217588

18659217588