- Language:

English ▼

English ▼

English ▼

English ▼ItemNo :

LITH-GKZYJ-02-1000MOQ :

1Delivery Time:

5 daysSemi-Automatic Electrolyte Filling Machine for Cylindrical Cells

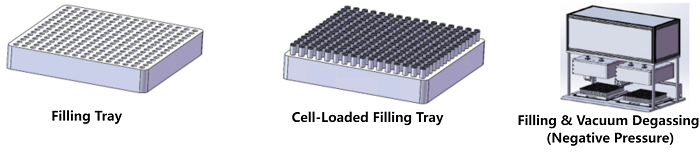

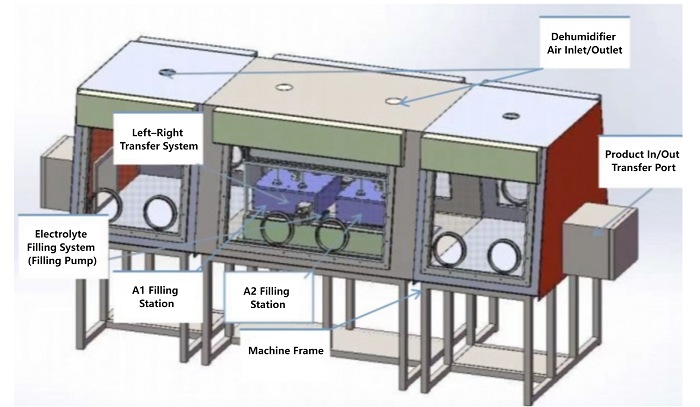

1.1 This equipment is mainly used on a semi-automatic assembly line for cylindrical cells inside a glove box, for electrolyte filling and pressurized degassing (vacuum pressurization).

1.2 Process flow: Pre-fill manual weighing → Manual loading (place cells onto tray) → Electrolyte filling → Pressurized degassing → Manual removal of cylindrical cells → Post-fill manual weighing.

|

Category |

Process Technical Parameters |

|

Equipment capacity |

Single machine ≥ 10 PPM (under continuous manual feeding; continuous production 2 h) |

|

Filling accuracy (per shot) |

±0.1 g |

|

Pump delivery precision |

≤ 3‰, digital intelligent adjustable pump |

|

Equipment utilization |

98% (only failures caused by this machine) |

|

First-pass yield |

99.4% (only defects caused by this machine) |

|

Compatibility |

Changeover by replacing tray and filling cup set (supplied for 21700) |

|

Glove box sections |

Three sections |

|

Gloves |

Three pairs (front & rear) |

|

Glove box material |

SUS304 |

|

Transition chamber size |

400 × 400 × 400 mm |

|

Top air inlet/outlet |

Ø110 |

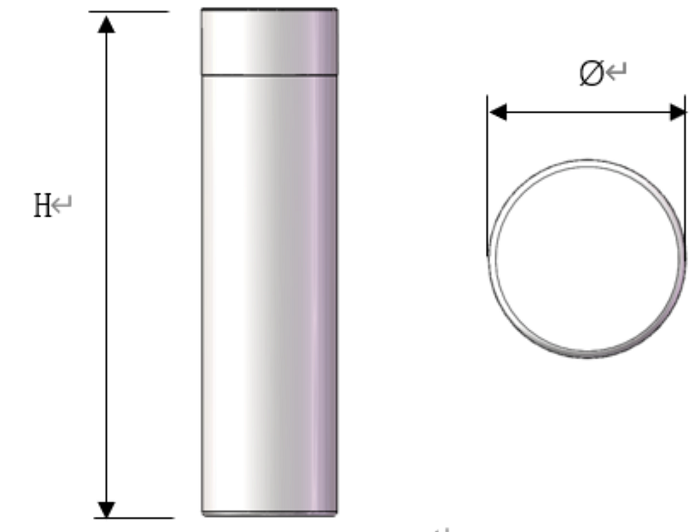

Cylindrical cell size range: (as per customer drawing/specification).

|

Code |

H (Height, mm) |

Ø (OD, mm) |

|

Min |

65 |

18 |

|

Max |

70 |

21 |

|

No. |

Mechanism |

Qty. |

Description |

|

1 |

Tray |

1 |

1) Tray is fixed inside the equipment. 2) For changeover, only the cup set and tray need replacement. |

|

2 |

Filling |

1 |

1) After filling, no dripping from the filling needle is allowed. 2) Storage-tank pressure is automatically controlled; the system de-gasses the electrolyte and has low-level detection with automatic replenishment. 3) Main filling line includes bubble-purge function. 4) A stainless-steel filter ≥ 200 mesh is installed before the pump (in the filling tank). 5) Filling-needle height is settable. |

|

3 |

Degassing |

1 |

1) Degassing time can be set 10–30 min as needed. 2) Isobaric (equal-pressure) degassing: evacuate the degassing chamber and the cells; cycle count configurable per process. 3) Vacuum regulation range: up to −95 kPa. 4) Pressure control accuracy ±5%; positive/negative pressure drop ≤ 2 kPa/min. |

|

4 |

Electrolyte tank system |

1 |

1) Two tanks: one for motor-assisted degassing/settling, one for filling. 2) Tanks placed in a sealed dry environment. 3) Automatic electrolyte feeding. 4) Four dedicated drip trays for liquid collection. 5) After liquid discharge, residual electrolyte in pipelines and buffer tank ≤ 500 g. Each filling tank has two level-sensing points; software can select/switch the detection position to ensure residual < 500 g in tank. |

|

5 |

Glove box |

1 |

1) Cylinder-actuated transition-chamber door. 2) Transparent PETG viewing windows. 3) Transition chamber ≈ 400 × 400 × 400 mm. 4) Each section top requires one Ø110 inlet and one Ø110 outlet. 5) Each section top reserves a 100 × 100 mm square port for internal electrical installation; fastened by screws and sealed with sealant. 6) Six lamp holders in total. 7) Main frame: 40-mm SUS square-tube welded structure. 8) Box & base plate: 2 mm SUS304 welded; outer surface brushed finish. |

|

6 |

Control system |

1 |

Industrial PC + PLC as the control core for all machine motions. |

1. Structural materials prioritized as aluminum and stainless steel or plated anti-corrosion to ensure no rust/oxidation.

2. Quick tray removal for maintenance (remove one machine tray within 35 min).

3. Workbench shall have electrolyte drainage grooves and a collection tank; cable ducts on the workbench shall be aluminum.

4. After bubbles occur, electrolyte discharge is convenient, routed to the collection tank.

5. Electrical cabinet made of stainless steel, polished matte; stainless-steel screws and nuts.

6. Main machine frame uses square tube with baked-paint finish; other parts consider anti-corrosion and wear-resistance; ensure no rust/oxidation.

7. Neat routing for cables and pipelines; overall coordination; drag chains used for long-travel motion.

8. The machine is mounted under an upper rack; the filling area is sealed. The rack glass uses anti-corrosion PC transparent panels. The top is connected to the plant exhaust to quickly extract electrolyte/DMC odors and keep humidity inside/outside consistent.

9. HMI modules shall be clear and user-friendly for operators.

|

No. |

Name |

Brand |

Notes |

|

1 |

Pneumatic components |

AIRTAC / Domestic |

|

|

2 |

Linear guide |

HIWIN |

|

|

3 |

Ball screw |

HIWIN |

|

|

4 |

Linear bearing |

YTP / HRB |

|

|

5 |

Servo motor / Driver |

Delta |

|

|

6 |

PLC |

Panasonic / Inovance / XINJE |

|

|

7 |

Touchscreen |

Weintek / XianKong |

|

|

8 |

Stepper motor |

Jianghua Motor |

|

|

9 |

AC motor |

Jianghua Motor |

|

|

10 |

Temperature-control system |

XINJE |

|

|

11 |

Intelligent electrolyte pump |

Dongguan Jiyanda (touchscreen adjustment, ceramic pump core) |

|

|

Category |

Specification |

|

Overall dimensions |

≈ L 3.8 m × W 1.8 m × H 1.8 m |

|

Weight |

2.5 T |

|

Floor load requirement |

> 500 kg/m² |

|

Power supply (by Buyer) |

Two-phase AC220 V ±10%, 50 Hz; Power: 7 kW |

|

Compressed air (by Buyer) |

0.5–0.7 MPa (5–7 kgf/cm²); 10 L/s; dried, filtered, regulated |

|

Vacuum (by Buyer) |

≤ −0.095 MPa; 40 L/s |

|

Relative humidity (by Buyer) |

0–90% RH |

|

Magnetic field & vibration (by Buyer) |

No magnetic field affecting the device; no shock or vibration |

|

No. |

Name |

Specification / Model |

Qty |

Manufacturer |

|

1 |

Cup-set O-ring |

Standard 16 × 1.5 mm O-ring |

200 |

— |

|

2 |

Pump O-ring |

Standard 22 × 2 mm O-ring |

20 |

— |

|

3 |

Filling-needle check valve |

Non-standard custom |

2 |

TMAX |

|

4 |

Hex wrench set |

1.5–10 mm |

1 set |

TGK |

|

5 |

Open-end wrench set |

6–22 mm |

1 set |

— |

|

6 |

Adjustable wrench |

Adjustable wrench |

1 pc |

— |

|

7 |

Screwdrivers |

101 flathead; 101 Phillips |

1 each |

— |

|

8 |

Toolbox |

— |

1 pc |

— |

![]()

![]()

![]()

1 Standard exported package: Internal anticollision protection, external export wooden box packaging.

2 Shipping by express, by air, by sea according to customers' requirements to find the most suitable way.

3 Responsible for the damage during the shipping process, will change the damaged part for you for free.

DELIVERY TIME:15-20 days after confirming the order, detail delivery date should be decided according to

production season and order quantity.

ONLINE

ONLINE +86 13174506016

+86 13174506016 Louis@lithmachine.com

Louis@lithmachine.com +86 18559646958

+86 18559646958

18659217588

18659217588