- Language:

English ▼

English ▼

English ▼

English ▼ItemNo :

LITH-YZFK-18AMOQ :

1Compliance:

CEWarranty:

2 yearsDelivery Time:

5 daysAutomatic Cylindrical Battery Sealing Machine for Glove Box Integration

1.1 Equipment Name:

Automatic Sealing Machine Inside Glove Box

1.2 Product Function:

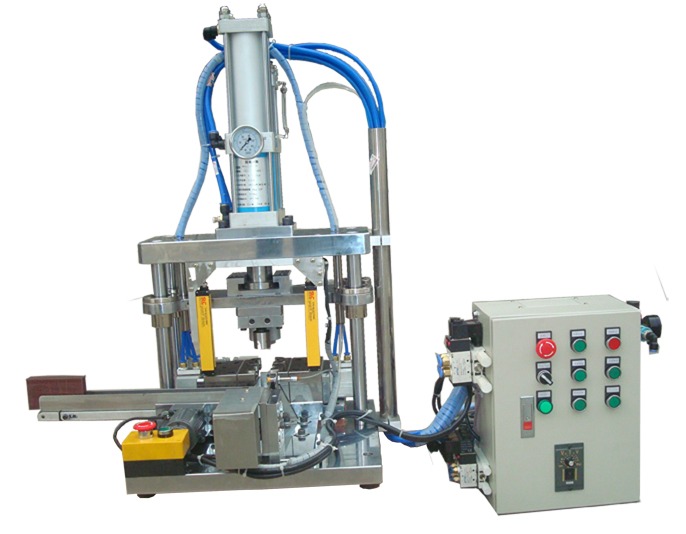

This equipment is specially developed for the cylindrical battery sealing process. It is a high-precision battery sealing machine, mainly used for the sealing of cylindrical batteries. The machine can complete pre-sealing, secondary sealing, and tertiary sealing in one operation.

It has stable and reliable performance, high sealing efficiency, good product consistency, simple operation, and easy maintenance. It is suitable for small-scale battery production.

1.3 Working Principle:

The working principle is that the transmission feeding groove drives the batteries for automatic feeding. Under the control of an electrical program, a cylinder pushes the batteries forward. Step-by-step feeding pushes the batteries sequentially into the mold.

The upper sealing air–hydraulic booster cylinder applies sealing force, generating huge pressure to compress the battery case and cover to the required process dimensions, thereby achieving the purpose of battery sealing.

l Airtac cylinders and Airtac electrical components

l Omron electrical control system

l SMC sensors

l Oil-resistant booster cylinder 5T

l Omron power supply

l Chint electric components

l Safety light curtain protection device

l Sealing range: Type 14 / 18 / 21

l Sealing speed: 25–30 pcs/min, adjustable speed

l Working pressure: 3T

l Total machine power: 250 W, 220V / 50Hz

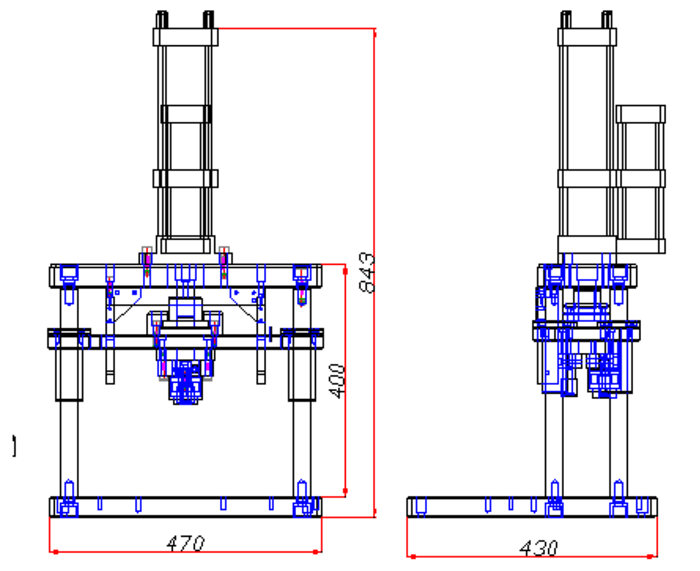

l Overall dimensions: 830 (L) × 430 (W) × 900 (H) mm

l Sealing steps: Pre-sealing, secondary sealing, tertiary sealing completed in one linkage operation

l Sealing pressure airtightness test: Can reach above 2 MPa

l Total equipment weight: 250 kg

l Working air pressure: Must reach ≥0.4 MPa for the equipment to start effectively; if lower than 0.4 MPa, the equipment will automatically alarm and stop

l Upper and lower sealing molds: Made of imported wear-resistant oil steel, with hardness after treatment reaching HRC 60–62

![]()

![]()

![]()

![]()

1 Standard exported package: Internal anticollision protection, external export wooden box packaging.

2 Shipping by express, by air, by sea according to customers' requirements to find the most suitable way.

3 Responsible for the damage during the shipping process, will change the damaged part for you for free.

DELIVERY TIME:15-20 days after confirming the order, detail delivery date should be decided according to

production season and order quantity.

ONLINE

ONLINE +86 13174506016

+86 13174506016 Louis@lithmachine.com

Louis@lithmachine.com +86 18559646958

+86 18559646958

18659217588

18659217588