- Language:

English ▼

English ▼

English ▼

English ▼ItemNo :

LITH-SGMOQ :

1Delivery Time:

5 days

Lab Small Manual Roller Rolling Press Machine For Battery Electrode

Introduction

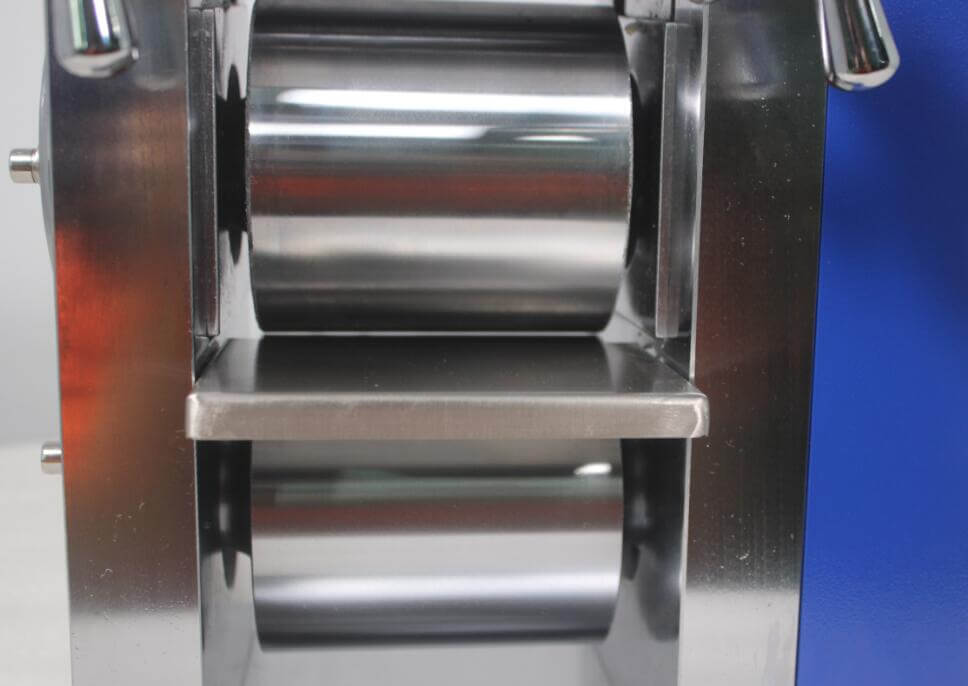

1 LITH-SG Lab Roll Press Machine is a Manual Rolling Press Machine. It has dual rollers of 100 mm dia. x 100mm-400mm width and dual grade micrometer.

This lab roll press machine is an ideal rolling press for adjusting thickness and increasing active material density of the electrode in Li-Ion batteries research after coating and drying.

2 This Lab roll press machine is mainly used in the laboratory lithium battery materials, small amount of precious metals such as gold and silver materials, copper, aluminum and other non-ferrous metal materials manually suppressed.

Specifications

|

Model |

Manual Rolling Press Machine LITH-SG |

|||||||||||||||||||

|

Structure |

1 Heavy duty steel frame, gears and handle |

|||||||||||||||||||

|

2 Φ100mm Dia.x 100-400mm width Rollers made from hardened tool steel (HRC > 60) with Cr electroplated coating |

||||||||||||||||||||

|

2 Dual micrometer for accurate thickness adjustment in the range 0 - 2 mm Maximum |

||||||||||||||||||||

|

Roller |

Dimensions: 100mm(Dia.) x 100mm-400mm(W) (the roller size can be customized) |

|||||||||||||||||||

|

Material: Made from hardened tool steel (HRC > 60) |

||||||||||||||||||||

|

with Cr electroplated coating. With finish > 0.8 |

||||||||||||||||||||

|

Rolling press accuracy |

≤±0.005 |

|||||||||||||||||||

|

Rolling press thickness |

0-2mm adjusted with Dial gauge |

|||||||||||||||||||

|

Product Dimensions |

350 mm(L) x 240mm(W) x 350mm(H) (14" x 9.5" x 14") |

|||||||||||||||||||

|

Weight |

45kg (100 lbs) |

|||||||||||||||||||

|

Application Notes |

This roller is specially designed for battery R&D in terms of its advantages as affordable,compact and precise. |

|||||||||||||||||||

|

1 Must use acetone to clean and dry rollers' surfaces after each use to avoid rusting |

||||||||||||||||||||

|

2 Coated Rust-proof oil if machine were to be unused for a long period of time |

||||||||||||||||||||

|

3 The minimum thickness of the rolled sheet should depend on the physical property of the materials. |

||||||||||||||||||||

|

Here are some results from our test:

|

![]()

Coin Cell Process:

Materilas → Powder Processing →Powder Grinding Mill → Vacuum Mixing → Electrode Coating → Roll Press → Vacuum Drying → Disc Cutter → Electrolyte Injection → Crimping Machine → Battery Analyzer

For the coin cell Assembly, we also recommend you the following items:

![]()

![]()

![]()

1 Standard exported package: Internal anticollision protection, external export wooden box packaging.

2 Shipping by express, by air, by sea according to customers' requirements to find the most suitable way.

3 Responsible for the damage during the shipping process, will change the damaged part for you for free.

DELIVERY TIME:15-20 days after confirming the order, detail delivery date should be decided according to

production season and order quantity.

ONLINE

ONLINE +86 13174506016

+86 13174506016 Louis@lithmachine.com

Louis@lithmachine.com +86 18559646958

+86 18559646958

18659217588

18659217588