|

Features

|

-

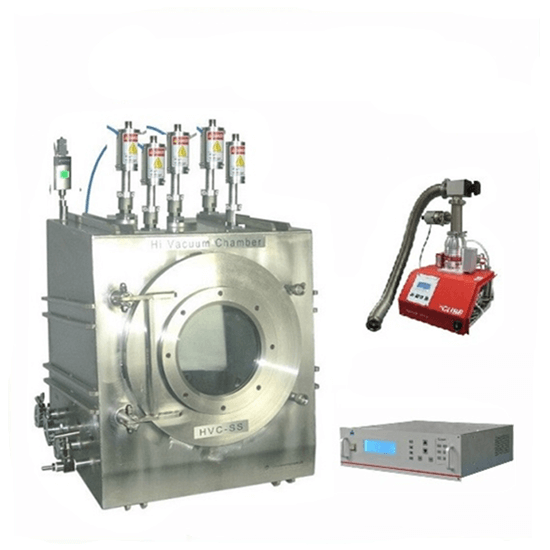

5 magnetron sputtering guns for 5 different target materials

-

Depending on the power supplies used (RF or DC), both metallic and non-metallic materials can be deposited.

-

Capable of sputtering 5 target materials to produce various compositions via different sputtering times / rates

-

With optional 5 power supplies, 5 target materials can be sputtered at the same time for combinatorial sputtering

-

16 samples can be deposited in one batch with a mask and a rotating sample holder

|

|

Input Power

|

-

Single phase 220 VAC, 50 / 60 Hz

-

1000 W (including vacuum pump and water chiller)

|

|

Power Source

|

-

One 13.5 MHz,300 W auto-match RF generator is included and connected to the sputtering heads

-

The rotatable switch can activate one sputtering head at a time. Sputtering heads can be switched “in the plasma” without breaking of vacuum during a multilayer process.

-

Multiple RF power supplies are optional, which allows user to sputter multi-target at the same time for combinatorial sputtering

-

Laptop with control software is available at extra cost to control each RF gun's sputtering time and power

|

|

Optional

|

-

You may choose DC power supply for metallic target sputtering

-

With five DC or RF power supplies, 5 target materials can be sputtered at the same time for combinatorial sputtering

|

|

Magnetron Sputtering Head

|

-

Five 1" magnetron sputtering heads with water cooling jackets are included and inserted into quartz chamber via quick clamps

-

RF cable replacement can be purchased at TMAX

-

One manually operated shutter is built on the flange (See Pic #3)

-

One 10 L/min digitally controlled recirculating water chiller is included for cooling sputtering heads

-

|

|

Sputtering Target

|

-

Target size requirement: 1" diameter x 1/8" thickness max

-

Sputtering distance range: 50 – 80 mm adjustable

-

Sputtering angle range: 0 – 25° adjustable

-

1" diameter Cu target and Al2O3 target are included for demo testing

-

Various oxide 1” sputtering targets are available upon request at extra cost

-

For target-bonding, 1 mm and 2 mm copper backing plates are included. Silver epoxy (Pic #1) and extra copper backing plates (Pic #2) can be ordered at TMAX

|

|

Vacuum Chamber

|

-

Vacuum chamber is made of 304 stainless steel with reinforcing rib

-

Inside vacuum chamber size: 470 mm L × 445 mm D × 522 mm H (~105 Liters, 18.5“x17.5"x 20.5")

-

Round 380 mm Dia. hinged type door with 150 mm Dia glass window

-

Temperature range: -15 to 150 °C

-

Vacuum level: 4.0E-5 torr with turbo pump

|

|

Sample Holder

|

-

150 mm diameter rotatable sample holder for coating 16 sample one one batch with different compositions

-

Sample holder and mask rotation can be controlled manually by a button or automatically by a control software (Optional)

-

The sample holder temperature is adjustable from RT to 600 °C max

|

|

Vacuum Pump

|

-

KF40 vacuum port is built in for connecting to a vacuum pump.

-

A compact turbo pump is included

-

4.0E-5 Torr with optional turbo pump

|

|

Optional

|

-

Precision quartz thickness sensor is optional. It can be built into the chamber to monitor coating thickness with accuracy 0.1 Å (water cooling required)

-

Easy USB connection to PC for remote thickness and coating speed monitoring

-

5 pcs quartz sensors (consumable) are included

|

|

Net Weight

|

|

|

Compliance

|

-

CE approval

-

MET Certification (UL 1450) is available upon request at extra cost, please contact our sales representative for quote.

|

|

Warranty

|

-

One years limited warranty with lifetime support

|

|

Application Notes

|

-

This compact 1" RF magnetron sputtering coater is designed for coating oxide thin films on oxide single crystal substrates, which usually does not need high vacuum set-up

-

A two-stage pressure regulator (not included) should be installed on the gas cylinder to limit the output pressure of gas to below 0.02 MPa for safe usage. Please use > 5N purity Ar gas for plasma sputtering

-

For the best film-substrate adhesion strength, please clean the substrate surface before coating:

-

Ultrasonic cleaning with the following sequential baths - (1) acetone, (2) isopropyl alcohol - to remove oil and grease. Blow dry the substrate with N2, then hot bake in vacuum to remove absorbed moisture

-

Plasma cleaning may be needed for surface roughening, surface chemical bonds activation, or additional contamination removal

-

A thin buffer layer (~5 nm), such as Cr, Ti, Mo, Ta, could be applied to improve adhesion of metals and alloys

-

For best performance, the non-conductive targets must be installed with a copper backing plate. Please refer to the instruction video below (#3) for target-bonding

-

Lith supplies single crystal substrate from A to Z

-

Lith RF Plasma Sputtering Coaters have successfully coated ZnO on Al2O3 substrate at 500 °C

-

Test the flexibility of the thin film/coated electrode with EQ-MBT-12-LD mandrel bending tester.

-

HIGH VOLTAGE! Sputtering heads connect to high voltage. For safety, the operator must shut down the RF generator before sample loading and target changing operations

-

DO NOT use tap water in water chiller. Use coolant, DI water, distilled water, or anti-corrosive additives with water

-

|

English ▼

English ▼ English ▼

English ▼![]()

![]()

![]()

![]()

ONLINE

ONLINE +86 13174506016

+86 13174506016 Louis@lithmachine.com

Louis@lithmachine.com +86 18559646958

+86 18559646958

18659217588

18659217588