- Language:

English ▼

English ▼

English ▼

English ▼ItemNo :

LITH-HDCG 3/4″-3MOQ :

1Warranty:

2yearsDelivery Time:

5 days

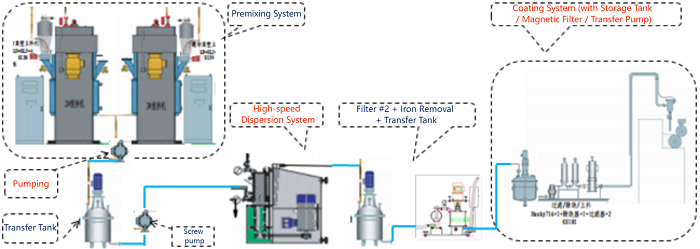

#1 Scheme:

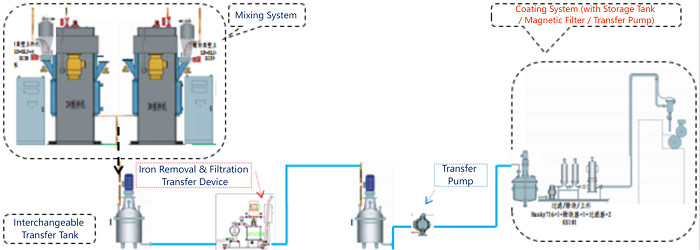

#2 Scheme:

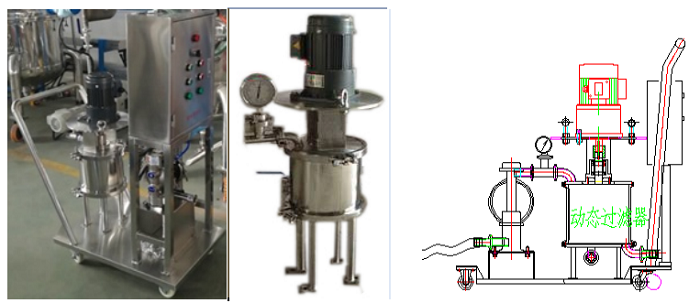

1. The slurry stored in the transfer tank is pumped via a diaphragm pump and piped through filter and de iron equipment, then delivered to the coating machine hopper.

2. All components are connected via quick disconnect fittings and supported on a stainless steel tray, with slurry transfer controlled via piping and the control system.

3. Important: The connecting pipeline valves and level control between this system and the coating hopper/storage tank must be installed and managed by the end user and coating machine supplier—as they are closely related to your facility and chosen coating line.

|

No. |

Name |

Model/Specification |

Unit |

Qty |

Remarks |

|

1 |

Pneumatic double diaphragm pump |

3/4″ – S.K.Y. or Graco |

pcs |

1 |

With standard ISO quick connect |

|

2 |

Filter cartridge |

Φ76 × 200 mm |

pcs |

1 |

100–250 mesh |

|

3 |

Magnetic rod |

Φ25 × 156 mm |

pcs |

3 |

10,000 Gauss each |

|

4 |

Pressure gauge |

Ø60 mm – 1 MPa |

pcs |

1 |

SUS304 stainless steel |

|

5 |

Squeegee (scraper) |

3 piece scraper set |

pcs |

1 |

Squeegee material: PTFE (Teflon); Spring in Japanese stainless steel |

|

6 |

Connection tube/valve/fittings |

Ø25 mm |

set |

1 |

SUS304 stainless steel |

|

7 |

Stainless steel tray |

Non standard (L×W×H) mm |

pcs |

1 |

SUS304 stainless steel |

|

8 |

System control cabinet |

Level, pressure, alarm, control |

pcs |

1 |

SUS304 stainless steel |

|

9 |

Conveyance capacity |

Operating capacity: 20 L/min |

– |

– |

– |

1. Shaft seals, squeegees, and filter cartridges are all consumable components.

2. This system is designed for continuous production using a single slurry formulation; frequent batch changes or intermittent operation are not recommended.

2-1. When switching slurry types, flush the pipelines and magnetic filters, replace key parts (filter cartridges, meshes), and it is advisable to replace the piping as well.

2-2. During normal operation, ensure that the pipelines are always filled with slurry to prevent air and moisture from entering, which could lead to slurry solidification.

2-3. External dimensions: 500 mm × 1000 mm × 900 mm (length × width × height).

Coin Cell Process:

Materilas → Powder Processing →Powder Grinding Mill → Vacuum Mixing → Electrode Coating → Roll Press → Vacuum Drying → Disc Cutter → Electrolyte Injection → Crimping Machine → Battery Analyzer

For the coin cell Assembly, we also recommend you the following items:

![]()

![]()

![]()

1 Standard exported package: Internal anticollision protection, external export wooden box packaging.

2 Shipping by express, by air, by sea according to customers' requirements to find the most suitable way.

3 Responsible for the damage during the shipping process, will change the damaged part for you for free.

DELIVERY TIME:15-20 days after confirming the order, detail delivery date should be decided according to

production season and order quantity.

ONLINE

ONLINE +86 13174506016

+86 13174506016 Louis@lithmachine.com

Louis@lithmachine.com +86 18559646958

+86 18559646958

18659217588

18659217588