- Language:

English ▼

English ▼

English ▼

English ▼ItemNo :

Lith-KJ5PMOQ :

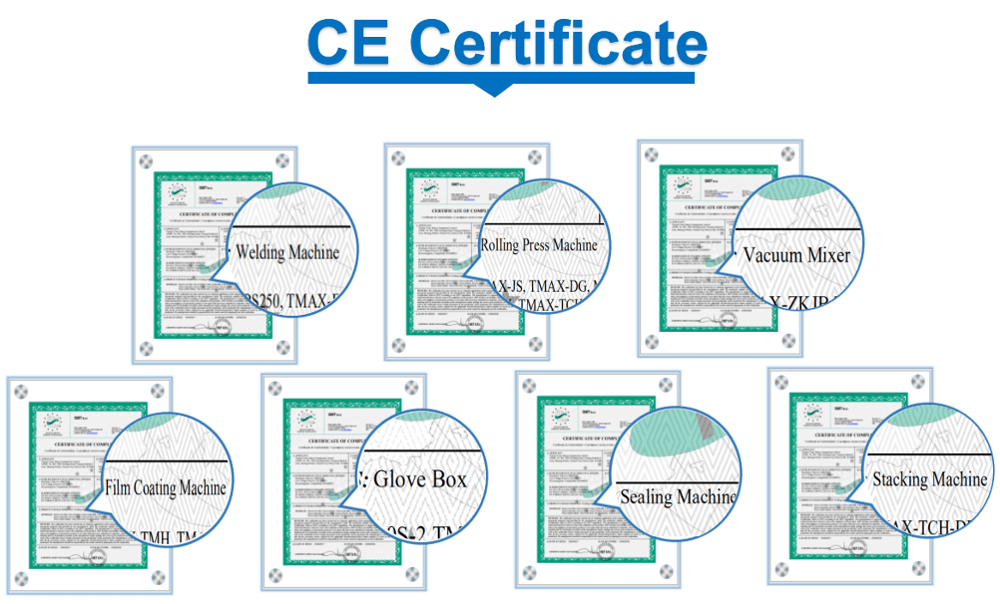

1Compliance:

CE CertifiedWarranty:

1 yearDelivery Time:

5 days

Chemical-Resistant Vacuum Spin Coater Unit With 10K RPM, 5" Chuck , 200°C Heating/UV

Application

Designed for thin-film coating processes in semiconductor, crystal, optical disc, and printing plate industries. Compatible with highly acidic/alkaline coating solutions.

1. Sample Fixation:

Vacuum chuck adsorption (up to -0.08MPa) ensures secure sample placement.

Includes two interchangeable polypropylene chucks (Φ19mm & Φ60mm) for varied sample sizes.

Centering tool minimizes eccentricity-induced vibration or sample slippage.

2. Programmable Control:

Stores 12 programs, each with 6 customizable stages.

Speed gradient control: Ramp rates (100–2000 rpm) prevent material waste and ensure uniform film thickness.

LCD + PCB microcontroller interface for intuitive operation (full English OS).

3. Motor & Performance:

24V DC brushless motor: Low noise, high stability, and rapid acceleration (500–10,000 rpm ±1% accuracy).

Ensures consistent coating uniformity and repeatability.

4. Vacuum System:

Oil-free dual-piston pump: Compact, maintenance-free, and environmentally friendly (exhaust flow ≥70 L/min).

Supports inert gas (Ar/N₂) environment for sensitive materials.

5. Construction:

Chamber: Chemical-resistant polypropylene (excellent stress-cracking resistance).

Body: Lightweight cast aluminum for durability.

6. Safety:

Lid-protection: Auto-deceleration upon opening during operation.

|

Parameter |

Detail |

|

Power Supply |

AC220V 50Hz, 10A (≤150W excluding pump) |

|

Speed Range |

500–10,000 rpm (adjustable in 100 rpm increments) |

|

Program Memory |

12 programs × 6 stages |

|

Stage Duration |

0–60 sec per stage |

|

Vacuum Pressure |

-0.08MPa (max) |

|

Chuck Material |

Polypropylene |

|

Dimensions |

450×340×280 mm (18 kg) |

· Environment: 0–45°C, 10–85% RH (non-condensing).

· Workspace: 800×600×700 mm bench (≥50 kg load capacity; cement recommended).

· Utilities:

o Single-phase grounded outlet (10A).

o Drain port for wastewater.

o No corrosive gases/vibrations nearby.

1. Vacuum chucks (Φ19mm & Φ60mm) with O-rings.

2. Centering tool (4 alignment pins).

3. Dropper +bracket.

4. Oil-free vacuum pump + rubber tube (clamped).

· Imported/domestic pipettes.

· Custom chuck sizes.

![]()

![]()

![]()

![]()

PACKAGE:

1 Standard exported package: Internal anticollision protection, external export wooden box packaging.

2 Shipping by express, by air, by sea according to customers' requirements to find the most suitable way.

3 Responsible for the damage during the shipping process, will change the damaged part for you for free.

DELIVERY TIME:15-20 days after confirming the order, detail delivery date should be decided according to

production season and order quantity.

ONLINE

ONLINE +86 13174506016

+86 13174506016 Louis@lithmachine.com

Louis@lithmachine.com +86 18559646958

+86 18559646958

18659217588

18659217588