- Language:

English ▼

English ▼

English ▼

English ▼ItemNo :

Lith-KJ5UMOQ :

1Compliance:

CE CertifiedWarranty:

1 yearDelivery Time:

5 days

10K RPM Spin Coater Supplier with Ultrasonic Spray - 5" Wafer Capacity & Optional PTFE Heating Cover

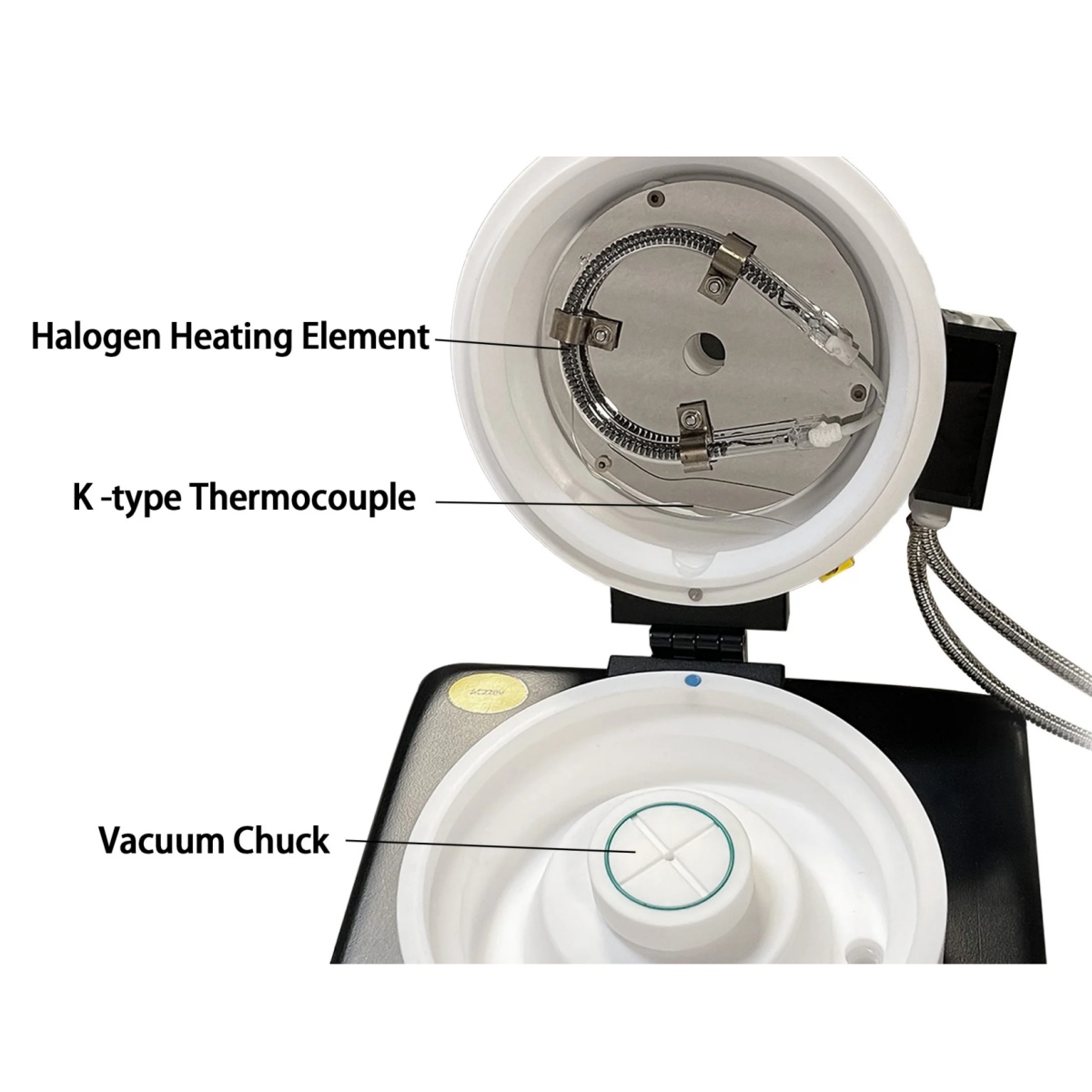

Lith-KJ5U is a benchtop spin coater supporting substrates up to 5" diameter with a maximum speed of 10,000 rpm, featuring a heat-resistant PTFE enclosure. The system includes dual ultrasonic spray nozzles and a temperature-controlled glass syringe for multifunctional operation, enabling either liquid atomization or heated solution dispensing. A precision DC servo motor drives the spin head with accurate speed/acceleration control, while vacuum chucking secures thin substrates. The intuitive interface combines a keyboard and LCD display for programming 12 customizable recipes with 6 segments each. All critical parameters (spin duration, speed, acceleration) are adjustable via the front panel. Corrosion-resistant construction ensures cleanroom compatibility.

Note: Compatible with glovebox operation under Ar atmosphere (requires external vacuum pump placement).

|

Category |

Specifications |

|

Key Features |

|

|

Programmable rotation speed |

500–10,000 RPM |

|

PTFE chamber heating |

Up to 200°C |

|

Substrate compatibility |

5 mm to 5" diameter |

|

Integrated ultrasonic spray nozzles |

Liquid atomization via gravity/low-pressure air |

|

Temperature-controlled glass syringe |

Max. 120°C (for heated solution deposition) |

|

Gas inlet port |

6 mm diameter (controlled atmosphere processing) |

|

Safety interlock |

Integrated into lid mechanism |

|

Liquid Injection Methods |

|

|

1. Ultrasonic Spray System |

• Titanium alloy nozzles with adjustable power controller (for spray pyrolysis) • Cylindrical nozzle: ~2 cm spray diameter (concentrated pattern) • Cone nozzle: ~4 cm spray diameter (wide pattern) |

|

2. Heated Dispensing |

Glass syringe with digital PID temperature control (max. 120°C) |

|

3. Standard Accessory |

20 mL plastic syringe included |

|

Coating Chamber |

|

|

Material |

PTFE (chemically resistant) |

|

Chamber diameter |

150 mm |

|

Maximum temperature |

200°C (≤10 minutes) |

|

Vacuum chucks |

PTFE (Ø40 mm and Ø10 mm, for 1"–4" wafers) |

|

Vacuum System |

120 L/min oilless pump, includes Ø8 mm plastic tubing |

|

Programmable Controls |

|

|

Program storage |

12 programs (6 segments each) • Segment duration: ≤60 sec • Acceleration: 100–2,000 RPM/sec (adjustable) |

|

Speed accuracy |

±5% |

|

Power Requirements |

|

|

Input voltage |

AC 220V (110V available upon request) |

|

Total power |

1,000 W (coater + pump) |

|

Motor type |

24V DC high-speed motor |

|

Optional Accessories |

|

|

PE heating cover |

PID-controlled (max. 120°C) |

|

UV LED curing system |

365 nm wavelength |

|

Glovebox feedthrough kit |

For Ar environments |

|

Plasma cleaner pre-treatment |

Recommended for optimal coating adhesion |

![]()

![]()

![]()

PACKAGE:

1 Standard exported package: Internal anticollision protection, external export wooden box packaging.

2 Shipping by express, by air, by sea according to customers' requirements to find the most suitable way.

3 Responsible for the damage during the shipping process, will change the damaged part for you for free.

DELIVERY TIME:15-20 days after confirming the order, detail delivery date should be decided according to

production season and order quantity.

ONLINE

ONLINE +86 13174506016

+86 13174506016 Louis@lithmachine.com

Louis@lithmachine.com +86 18559646958

+86 18559646958

18659217588

18659217588