ItemNo :

LITH-CY5V2A-64CHMOQ :

1Compliance:

CEWarranty:

2 yearsDelivery Time:

5 daysEmail :

Louis@lithmachine.com

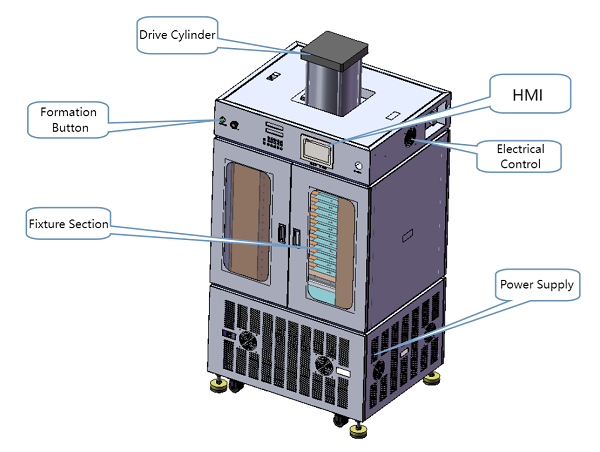

5V 2A 64-Channel Pouch Battery Hot Press Formation Machine

The equipment is composed of six major systems: temperature control, over/under-temperature alarm, over/under-voltage alarm, pressure control, formation cabinet system, and fixture mechanism.

It features: Independent temperature control for each board layer, pressure control, charge/discharge functions, overcharge/discharge protection, reliable contact between battery tabs and contact points, data connectivity, data storage upon process completion, voltage sorting after charging, capacity sorting after discharging, and smoke alarm system.

3. Equipment Structure

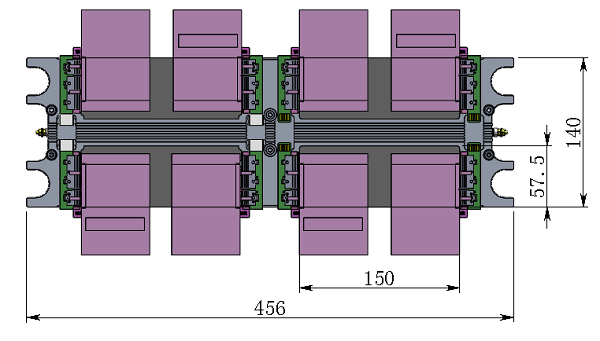

4. Fixture Structure and Overall Dimensions (for reference)

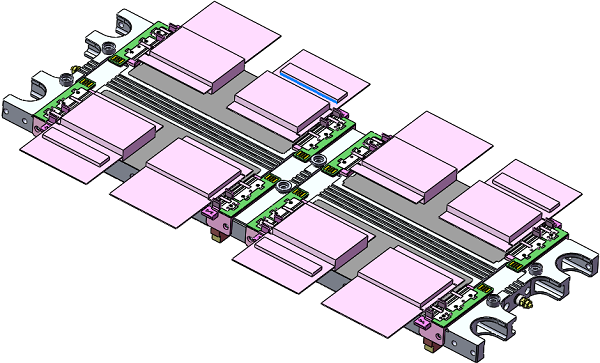

5. Battery Placement

(8 Cells per Layer )

(Airbag on Outer Side)

Power On → Open Cabinet Door → Place Cells in Fixture → Set Fixture Parameters → Fixture Descends & Starts → Place Next Set → Remove Batteries After Process Completion

· Supports battery thickness range of 2.5–11 mm without fixture adjustment or tab block replacement

· Fixture aluminum plates are 17mm thick, grid-structured, lightweight, high-strength, non-deforming

|

No. |

Parameter |

Specification / Description |

|

1 |

Heating Method |

Built-in heating tube, fire-resistant and corrosion-resistant |

|

2 |

Temperature Control |

Independent per layer, touchscreen setting |

|

3 |

Plate Structure |

Grid aluminum with stainless steel on both sides, laminated with namecard paper |

|

4 |

Time to 40℃ |

15–20 minutes (target temperature 65℃) |

|

5 |

Temperature Range |

Ambient to 85℃, control accuracy: ±2℃ |

|

6 |

Pressure Range |

80–1900 KG (Cylinder diameter: 200mm) |

|

7 |

Cylinder Drive |

Top-down vertical pressing |

|

8 |

Weight Reduction |

Hollow aluminum plates |

|

9 |

Pressure Accuracy |

≤±15KG (top and bottom layers) |

|

10 |

Sending Mode |

Single fixture independent step; system-wide temperature and pressure control |

|

11 |

Pressure Setup |

Input cell size, required surface pressure and duration; system calculates and applies automatically |

|

12 |

Plate Spacing |

19mm (easy operation) |

|

13 |

Tab Contact |

Gold-plated copper spring clips |

|

14 |

Tab Block |

Teflon injection molding (flame-retardant, corrosion-resistant) |

|

15 |

Constant Current Channels |

64 channels, software controlled |

|

16 |

Voltage Output Range |

DC 20mV ~ 4500mV |

|

17 |

Voltage Accuracy |

±0.1%FS ±0.1%RD, resolution: 1mV |

|

18 |

Current Range |

DC 20 ~ 2000mA |

|

19 |

Current Accuracy |

±0.1%FS ±0.1%RD, resolution: 1mA |

|

20 |

Step Count |

1–32 steps |

|

21 |

Product Yield |

≥98% (excluding non-equipment factors) |

Applicable Cell Parameters

|

|

Parameter |

Range |

|

Cell Length (A) |

12–60mm (cells >60mm: place at half density) |

|

|

Cell Width (B) |

9–50mm |

|

|

Cell Thickness (H) |

2.5–11mm(shared press block) |

|

|

Tab Spacing (C) |

3–35 mm |

|

|

Tab Shoulder (D) |

≤14 mm |

|

|

Tab Length (E) |

≥6 mm |

|

|

Polarity Direction |

Airbag side is negative side |

III. Main Software Functions

1. Working Modes: Constant current charging, constant current/constant voltage charging, constant current discharging, rest, and cycling

Cut-off Conditions: Voltage, time, final current, final capacity

2. Formation Step Control: Supports power failure resume, manual pause/resume, software resume, communication interruption resume, abnormal stop resume

3. Data Management: Saves all process curves for each battery. Real-time and historical data can be viewed for each channel. Supports Excel export (single or batch). Can be configured for auto-export at test end.

4. Battery Inspection Interfaces: Graphical view, comprehensive view, categorized view, and abnormal data view.

5. Safety Protections: Voltage, current, temperature, and pressure anomaly protection with alarms.

6. Minimum PC Configuration: CPU PII/300+, 1GB RAM+, 80GB HDD+, EGA/VGA display, mouse and keyboard, Windows 2000 or above, 1 USB serial port

7. Software Provided: Comes with control software. Users supply their own PC. One PC provided for up to 6 units.

8. Protection Functions:

(1) Software overvoltage, undervoltage, overcurrent, undercurrent, overcapacity protection

(2) Configurable voltage/current thresholds with warnings and logs

(3) Temperature/pressure alarm indicators

(4) Emergency stop button: keeps fixture clamped and cuts power

(5) Smoke alarm with buzzer alert

9. Status Light Indicators:

(1) Yellow: Standby (fixture not pressed)

(2) Green: Processing (pressed & charging)

(3) Red: Fault (temperature, voltage, smoke, communication, etc.)

1. Power Supply: AC380V, 50Hz, three-phase four-wire; voltage fluctuation: ±10%

2. Power Consumption: MAX 1.3 KW; steady state at 1000mA: approx. 0.35 KW

3. Compressed Air: 0.6–0.8 MPa; ±1% fluctuation (clean, dry, oil-free, filtered, regulated)

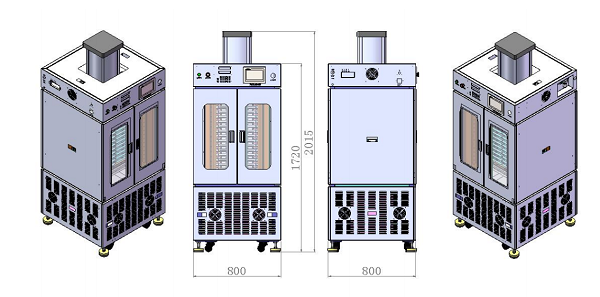

4. Equipment Specifications:

· Weight: approx. 0.6 tons

· Color: Light gray or customer-specified

5. Environmental Requirements:

· Temperature: 0–45℃

· Humidity: 30%–75% RH; dry, ventilated, non-corrosive

Grounding: Protective earthing required

![]()

![]()

![]()

PACKAGE:

1 Standard exported package: Internal anticollision protection, external export wooden box packaging.

2 Shipping by express, by air, by sea according to customers' requirements to find the most suitable way.

3 Responsible for the damage during the shipping process, will change the damaged part for you for free.

DELIVERY TIME:15-20 days after confirming the order, detail delivery date should be decided according to

production season and order quantity.

ONLINE

ONLINE Louis@lithmachine.com

Louis@lithmachine.com +0086 15959378975

+0086 15959378975