- Language:

English ▼

English ▼

English ▼

English ▼ItemNo :

LITH-PFSCMOQ :

1Compliance:

Warranty:

2yearsDelivery Time:

5 days

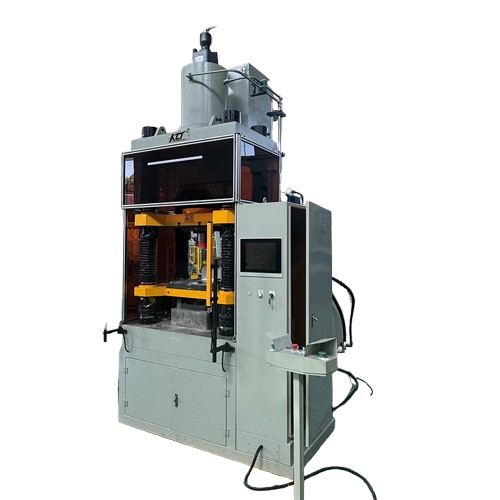

Introduction

The electronic ceramic powder servo forming machine uses a servo motor to drive the lead screw, which in turn drives the upper punch, mother mold and lower punch to perform high-precision up and down movements. The powder is injected into the female mold through the hopper, material pipe and material shoe to achieve fully automatic functions such as powder pressing and forming, demolding, material picking and tray loading. Pressure accuracy ±1%; Displacement accuracy ±0.01mm;

Drive mode: Pure electric, oil on top and electricity at the bottom, servo hydraulic

Formwork structure: top one bottom one, top one bottom two, top one bottom three, top two bottom two, top two bottom three, top two bottom four;

Product features

1. High-precision control

The servo press is equipped with an independent servo system and electrical system, capable of achieving floating pressing, precisely controlling pressure and displacement, and thus enabling high-precision shaping of fine powders. The forming accuracy can reach within 0.02mm, and the repeatability accuracy can reach within 0.005mm.

2. Flexible formwork structure

The die frame structure is diverse, including top-one-bottom-one, top-one-bottom-two, top-one-bottom-three, top-two-bottom-two, top-two-bottom-three, top-two-bottom-four, etc. It is suitable for pressing complex products with multiple section differences and multiple blind holes.

Quick effect, long service life, high quality and wide adaptability.

3. Multiple driving modes

Servo presses can adopt various drive methods, such as upper punch servo hydraulic cylinder drive + lower punch servo hydraulic cylinder drive, or upper punch AC servo motor + direct lead screw drive + lower punch AC servo motor + direct lead screw drive, etc., to ensure precise control of pressure and displacement, to meet different pressing requirements .

4. Intelligent automatic molding, saving time and effort

It features fully automatic functions such as powder feeding, molding, demolding, material picking and tray loading

Record and analyze the product forming process to achieve flexible line assembly operations

5. High efficiency and stability

Efficiency and stability : The equipment operates stably, is easy to operate, and is equipped with a mechanical limit device to ensure the consistency of the products. Meanwhile, the equipment has a simple structure, is easy to maintain, and is environmentally friendly and energy-saving.

Application

The electronic ceramic powder servo forming machine is suitable for the metal magnetic powder core industry, ferrite industry, multi-pole magnet industry: forming of powder products such as alumina, zirconia, silicon carbide, aluminum nitride, silicon nitride, and silicon oxide, such as: electronic ceramics, precision ceramics, ceramic structural components, 5G filters, fasteners, connectors, etc.

Technical parameter

|

Dry powder forming machine |

|||||||

|

Item |

Unit |

40T |

63T |

100T |

160T |

200T |

|

|

Nominal force |

KN |

400 |

630 |

1000 |

1600 |

2000 |

|

|

The maximum distance point between the lower plane of the slider and the worktable surface |

mm |

It is determined based on the type of cross frame and the loading height |

|||||

|

Slider operation parameters |

Maximum suppressing force |

KN |

400 |

630 |

1000 |

1600 |

2000 |

|

Maximum return force |

KN |

180 |

100 |

100 |

160 |

240 |

|

|

Maximum itinerary |

mm |

350 |

400 |

400 |

400 |

400 |

|

|

Rapid downward speed |

mm/s |

150 |

150 |

160 |

160 |

160 |

|

|

Slow downward speed |

mm/s |

15 |

15 |

15 |

10 |

12 |

|

|

Proportional floating pressing speed |

mm/s |

10-15 |

10-15 |

10-15 |

10-15 |

8-15 |

|

|

The speed of the rear pressure suppression |

mm/s |

10 |

10 |

10 |

10 |

12 |

|

|

Return speed |

mm/s |

140 |

140 |

150 |

160 |

170 |

|

|

Ejection piston operation parameters |

Maximum top force |

KN |

230 |

230 |

340 |

340 |

650 |

|

Maximum pulling force |

KN |

300 |

300 |

480 |

480 |

780 |

|

|

Maximum itinerary |

mm |

150 |

150 |

150 |

180 |

200 |

|

|

Lifting speed |

mm/s |

30 |

65 |

30 |

65 |

35 |

|

|

Floating downward velocity |

mm/s |

10-15 |

10-15 |

10-15 |

10-15 |

8-12 |

|

|

Return speed |

mm/s |

45 |

95 |

45 |

95 |

45 |

|

|

Operating parameters of the lower center cylinder piston |

Maximum outstretched force |

KN |

60 |

60 |

60 |

60 |

80 |

|

Maximum retraction force |

KN |

35 |

35 |

35 |

35 |

50 |

|

|

Maximum itinerary |

mm |

100 |

100 |

100 |

120 |

120 |

|

|

Main motor power |

KW |

12 |

12 |

12 |

15 |

22 |

|

|

Working frequency |

times/min |

2-8 |

|||||

|

High consistency of products |

mm |

±0.05-±0.2 |

|||||

![]()

![]()

![]()

1 Standard exported package: Internal anticollision protection, external export wooden box packaging.

2 Shipping by express, by air, by sea according to customers' requirements to find the most suitable way.

3 Responsible for the damage during the shipping process, will change the damaged part for you for free.

DELIVERY TIME:15-20 days after confirming the order, detail delivery date should be decided according to

production season and order quantity.

ONLINE

ONLINE +86 13174506016

+86 13174506016 Louis@lithmachine.com

Louis@lithmachine.com +86 18559646958

+86 18559646958

18659217588

18659217588