- Language:

English ▼

English ▼

English ▼

English ▼ItemNo :

GSL-1100X-SPC-16C-LDMOQ :

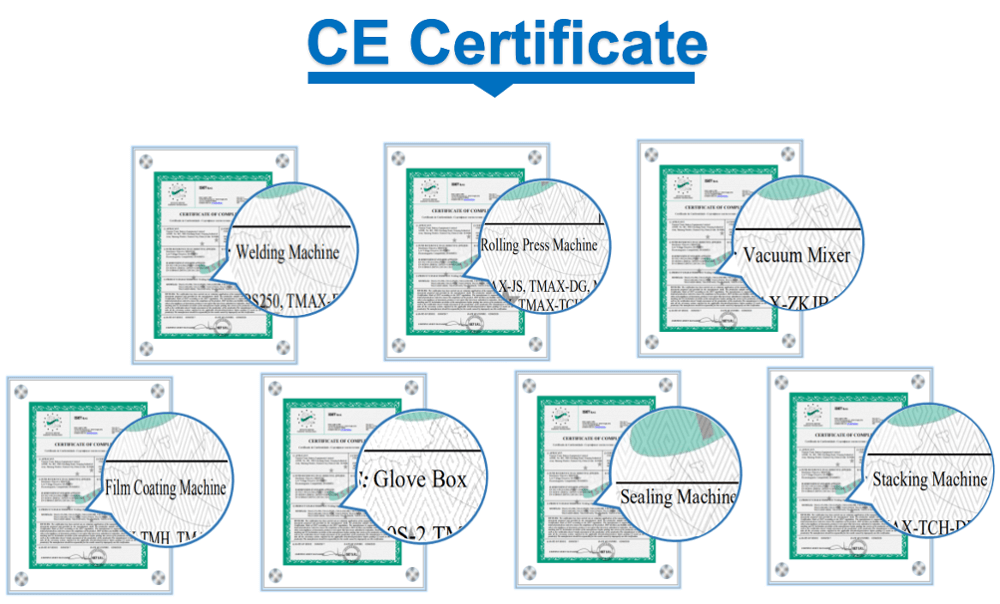

1Compliance:

CE CertifiedWarranty:

1 yearDelivery Time:

5 days

GSL-1100X-SPC-16C-LD is a two in one compact coating unit with Double Step Rotary Vane Vacuum Pump, which integrates plasma sputtering and evaporating into one small machine. It is specially designed for preparing SEM and EDAX sample for microstructure and micro-area composition analysis in material analysis at low cost. to coat various materials, including carbon.

SPECIFICATIONS

|

Input Voltage |

208 - 240 VAC, single phase, 50/60 Hz |

|

Power |

< 2000W (including pump) |

|

|

|

|

Working chamber |

|

|

Coating Head |

|

|

|

|

|

|

|

|

Gas atmosphere |

One needle valve installed to allow Ar gas inlet to achieve better plasma coating |

|

Target & Evaporating source |

|

|

Overall dimension |

L360mm x W300mm x H380mm |

|

Net Weight |

50 kg |

|

Compliance |

|

|

Warranty |

One year limited with lifetime support |

|

|

|

![]()

![]()

![]()

![]()

1 Standard exported package: Internal anticollision protection, external export wooden box packaging.

2 Shipping by express, by air, by sea according to customers' requirements to find the most suitable way.

3 Responsible for the damage during the shipping process, will change the damaged part for you for free.

DELIVERY TIME:15-20 days after confirming the order, detail delivery date should be decided according to

production season and order quantity.

ONLINE

ONLINE +86 13174506016

+86 13174506016 Louis@lithmachine.com

Louis@lithmachine.com +86 18559646958

+86 18559646958

18659217588

18659217588