- Language:

English ▼

English ▼

English ▼

English ▼ItemNo :

Lith-KJ-4AMOQ :

1Compliance:

CE CertifiedWarranty:

1 yearDelivery Time:

5 days

High-Speed 8000 RPM Vacuumless Spin Coater for 4 Inch Wafers

Product Introduction

The Lith-KJ-4A Spin Coater employs an advanced power supply system where the motor and control units operate on independent power sources. Its speed regulation system utilizes a high-interference-resistance microcontroller, ensuring exceptional speed stability within a broad range of 1000–8000 RPM.

The machine automatically stops after the preset homogenization time, completing the entire coating cycle.

Core Parameters

|

Category |

Specification |

|

Power Input |

AC 220V/110V, 50/60Hz (10A fuse, φ5×20mm) |

|

Power Consumption |

≤150W |

|

Chuck Material |

Polypropylene, φ100mm (grooved for substrate retention) |

|

Rotation Direction |

Counterclockwise |

|

Speed Range |

SPD1 (Low Speed): 500–8000 RPM <br> SPD2 (High Speed): 500–8000 RPM |

|

Timer Settings |

T1 (Low Speed Time): 1–60s <br> T2 (High Speed Time): 1–60s |

|

Speed Stability |

±1% |

|

Control System |

Microcontroller (PCB-based), keypad interface, digital display |

|

Dimensions |

260mm × 380mm × 330mm (L×W×H) |

|

Weight |

12kg |

Standard Accessories

|

Item |

Quantity |

Description |

|

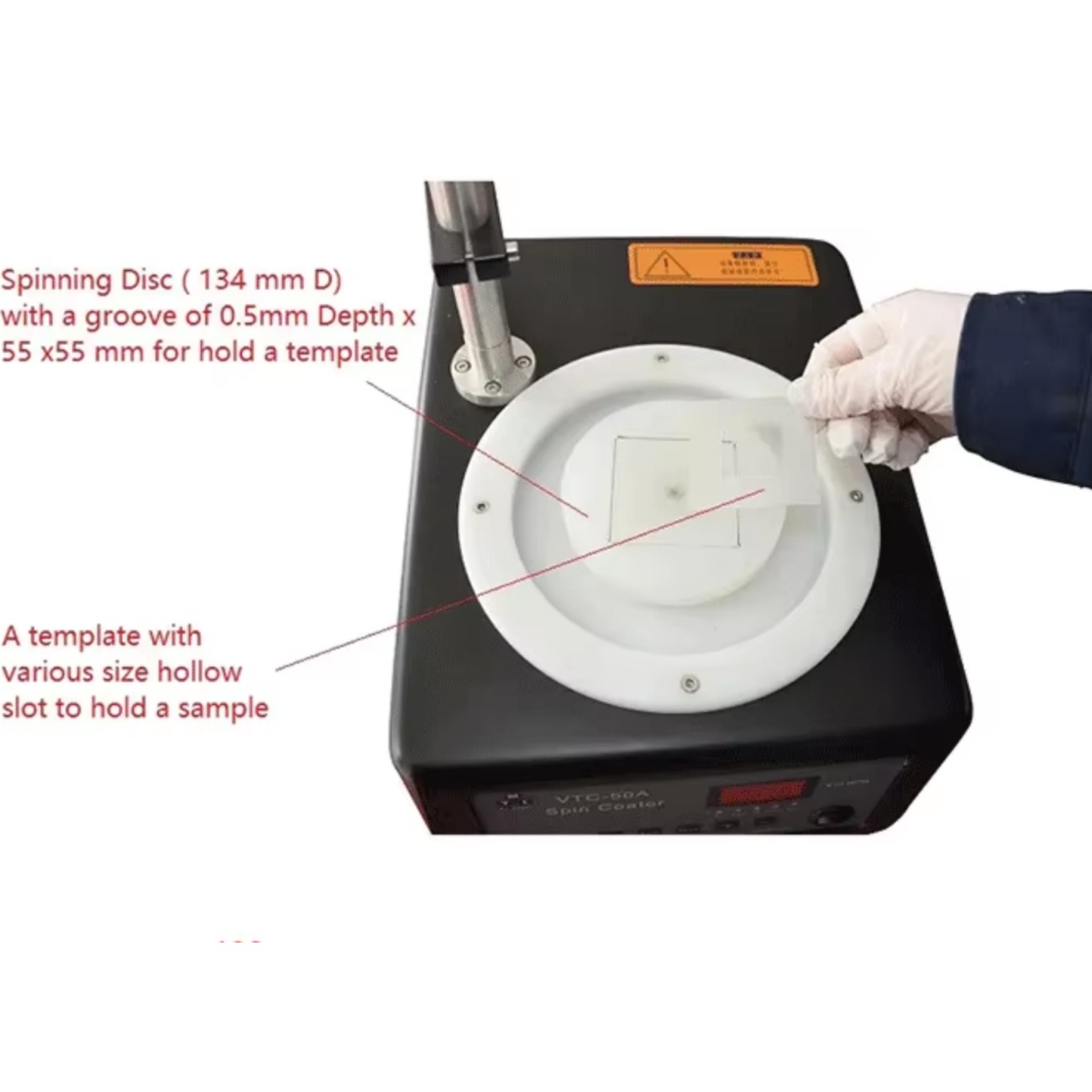

Polypropylene Sample Chuck |

1 |

Includes 55×55mm sample groove |

|

Resin Base Pad |

1 |

Provides stable support during operation |

|

Liquid Dropper |

1 |

For precise liquid dispensing |

|

Templates |

5 |

Customizable for different substrate shapes/sizes |

Optional Accessories

|

Item |

Type |

Notes |

|

Pipette (Domestic) |

Optional |

Compatible with standard liquids |

|

Pipette (Imported) |

Optional |

Higher precision for sensitive applications |

The coating process consists of two distinct phases:

· Phase 1 (SPD1 & T1): Low-speed rotation for gradual dispersion of film-forming liquid, completing the glue dispensing stage.

· Phase 2 (SPD2 & T2): High-speed rotation for uniform distribution of the liquid on the substrate, achieving precise film homogenization.

The Lith-KJ-4A is designed for processing liquids, gels, and flowable pastes, enabling rapid formation of uniform thin films on substrates through controllable high-speed rotation. It features a grooved polypropylene sample chuck for secure, non-damaging substrate fixation. Customizable template slots accommodate varying substrate shapes and sizes.

![]()

![]()

![]()

![]()

PACKAGE:

1 Standard exported package: Internal anticollision protection, external export wooden box packaging.

2 Shipping by express, by air, by sea according to customers' requirements to find the most suitable way.

3 Responsible for the damage during the shipping process, will change the damaged part for you for free.

DELIVERY TIME:15-20 days after confirming the order, detail delivery date should be decided according to

production season and order quantity.

ONLINE

ONLINE +86 13174506016

+86 13174506016 Louis@lithmachine.com

Louis@lithmachine.com +86 18559646958

+86 18559646958

18659217588

18659217588